Multi-vehicle edge rolling flexible switching system

A switching system and multi-vehicle technology, applied in the field of body-in-white hemming welding production line, can solve the problems of unfavorable enterprise application, complex system structure, high manufacturing cost, etc., and achieve the effect of high repeat positioning accuracy, simple positioning method and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

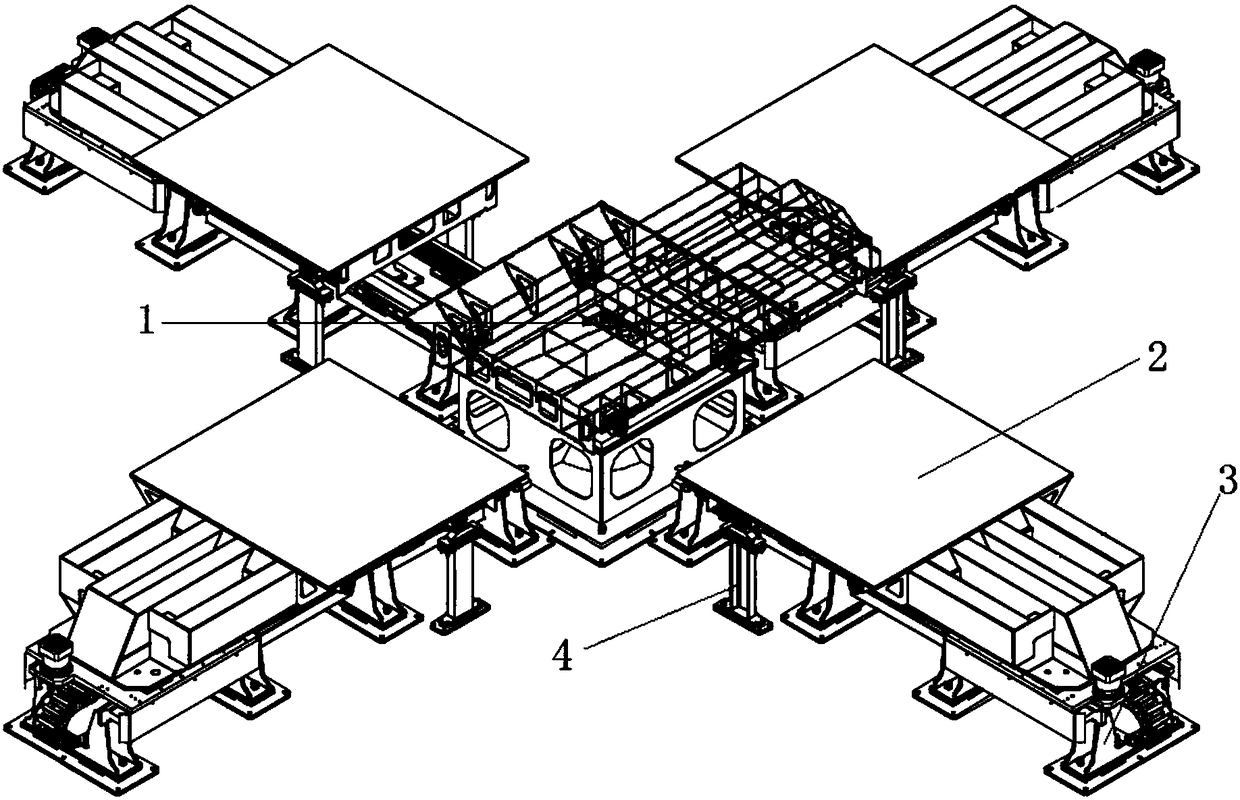

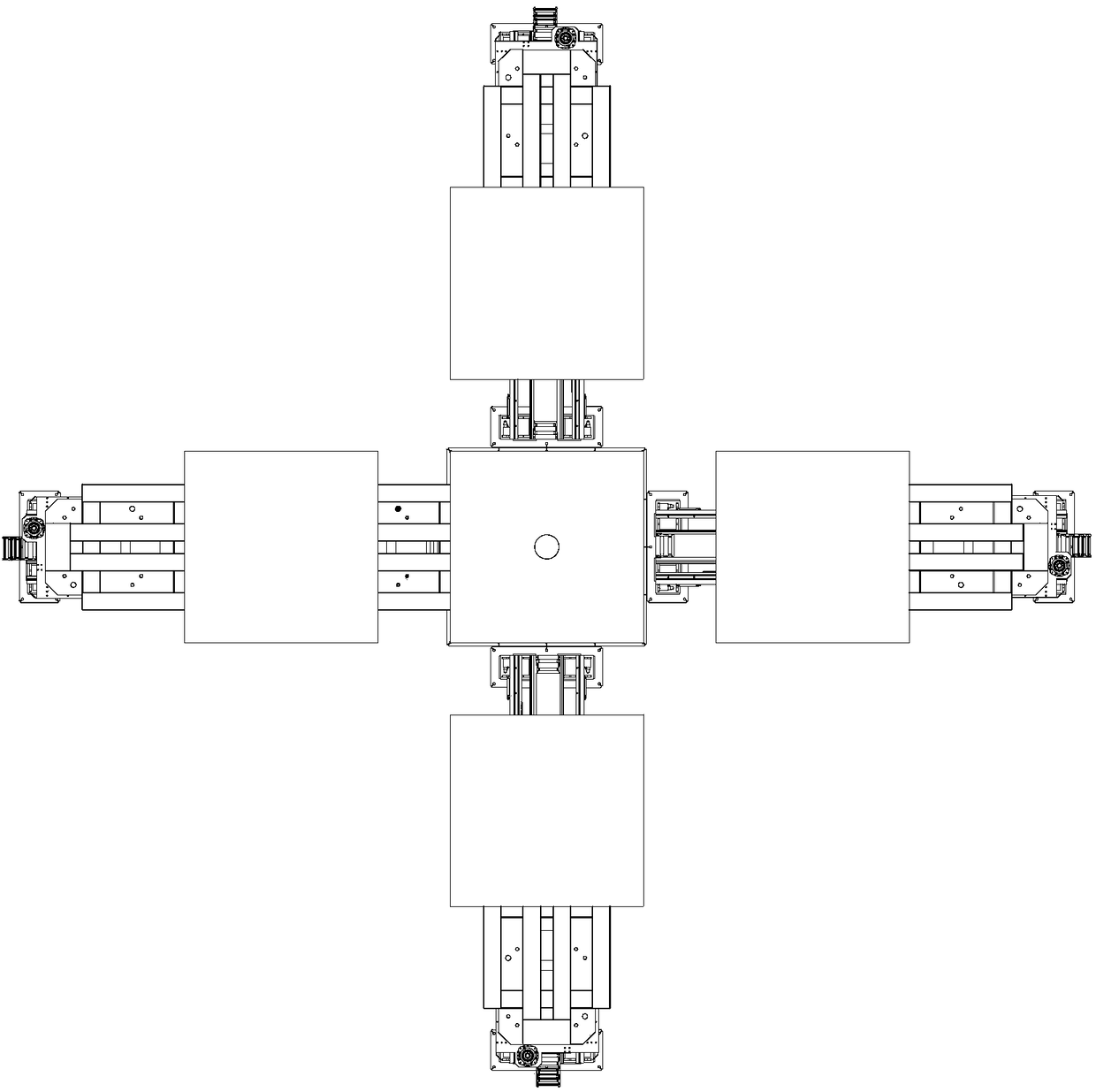

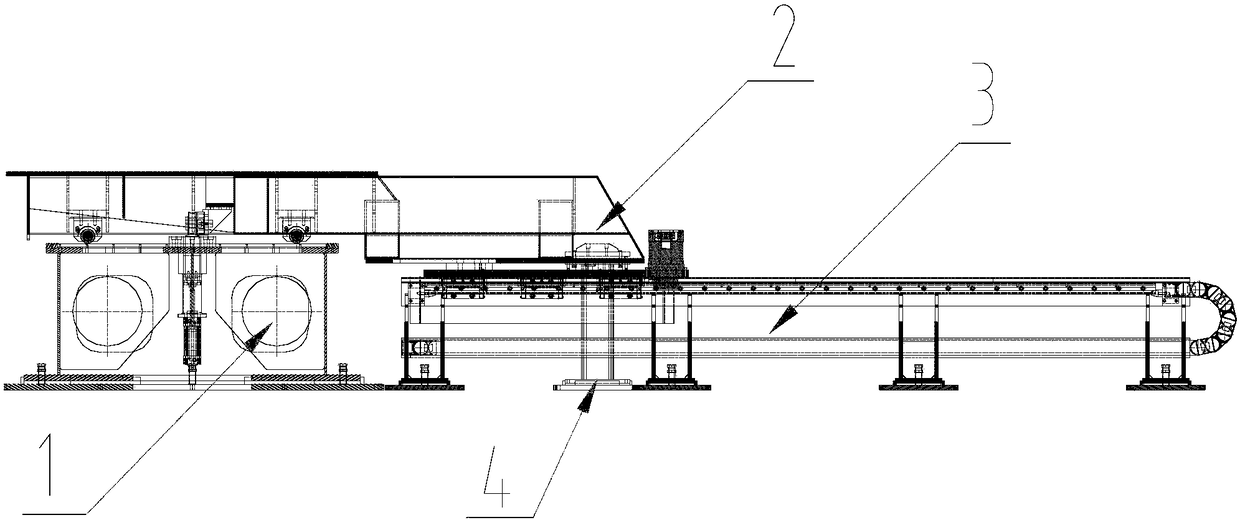

[0026] refer to Figure 1-8 The flexible track switching system of this embodiment is composed of a central working station 1 and four conveying line mechanisms distributed in a cross shape. The conveying line mechanism includes a slide unit 2 and a track unit 3. The slide unit 2 is installed on the track unit 3 and Moving along it, the slide unit 2 is provided with a positioning part 24, and the positioning part 24 is composed of a pair of positioning rollers with a gap. The slider unit 2 is positioned through the gap of the positioning rollers, and the bottom of the positioning shaft 12 is connected to the driving cylinder. The sliding table unit 2 includes a sliding table base frame 21. The sliding table basic frame 21 is equipped with a gear motor 23 that drives the sliding table unit 2 to move. Both sides of the sliding table basic frame 21 are provided to guide the sliding table unit 2 to move at the central working position 1. The walking roller 22 of the track unit 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com