The tightening and control device of the roll gap measuring arm of the pincer-type online roll gap meter

A control device and measuring arm technology, applied in the configuration of indicating equipment/measuring equipment, manufacturing tools, casting equipment, etc., can solve the problems of damaged roll gap meter mechanism and roll gap probe damage, and achieve the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

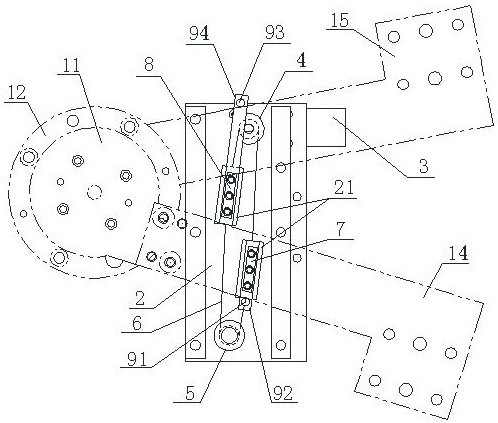

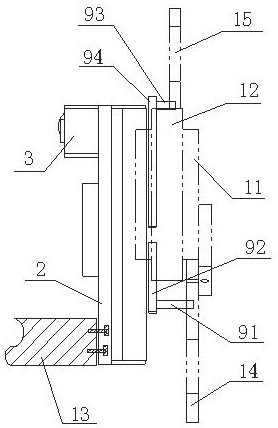

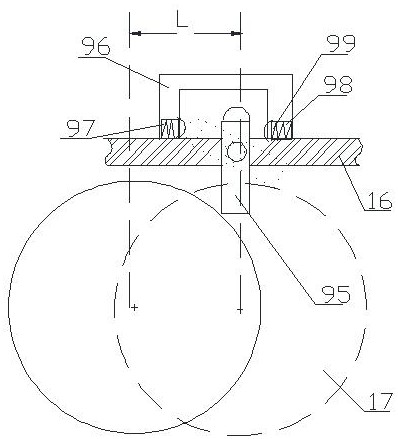

[0014] The tightening and control device of the clamp-type online roll gap measuring arm of the present invention comprises a rotating shaft 11, a rotating sleeve 12, a mounting base 13, an upper measuring arm 14 and a lower measuring arm 15 of the rolling gap meter. 11 is set in the roll gap meter box 16 through the mounting seat 13, the rotating shaft sleeve 12 is inserted into the rotating shaft 11, the upper measuring arm 14 is connected to the rotating shaft 11, and the lower measuring arm 15 is connected to the rotating shaft Axle sleeve 12, this device also comprises base plate 2, driving motor 3, driving sprocket 4, driven sprocket 5, chain 6, upper slider 7, lower slider 8, the upper connecting arm 92 of belt hook end 91, belt The lower connecting arm 94 of the hook end 93, the trigger lever 95 and the combined switch, the base plate 2 is arranged on the mounting seat 13 and is positioned behind the upper measuring arm 14 and the lower measuring arm 15, the driving spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com