Portable underwater wet-method non-electric welding method

A welding method and portable technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of inability to meet the needs of maneuverability, limit the flexibility of welding maneuvers, danger of electric shock in underwater arc welding, etc., and achieve recovery. The effect of equipment combat effectiveness, extended docking maintenance cycle, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

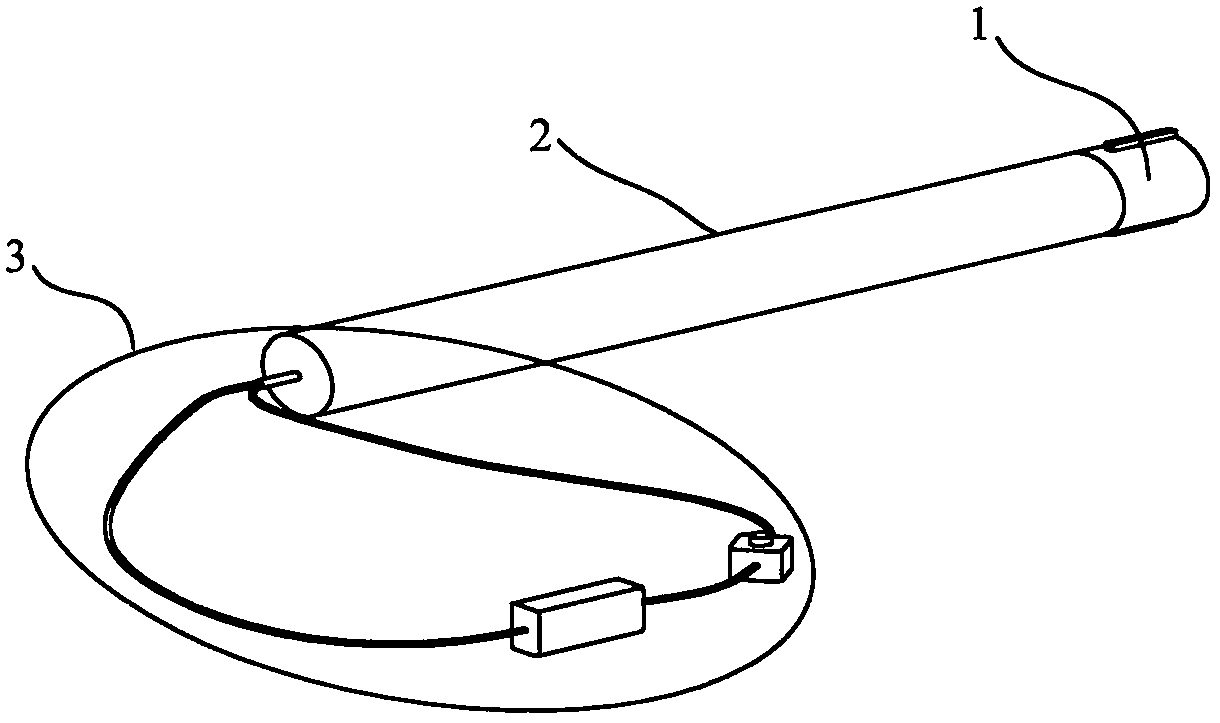

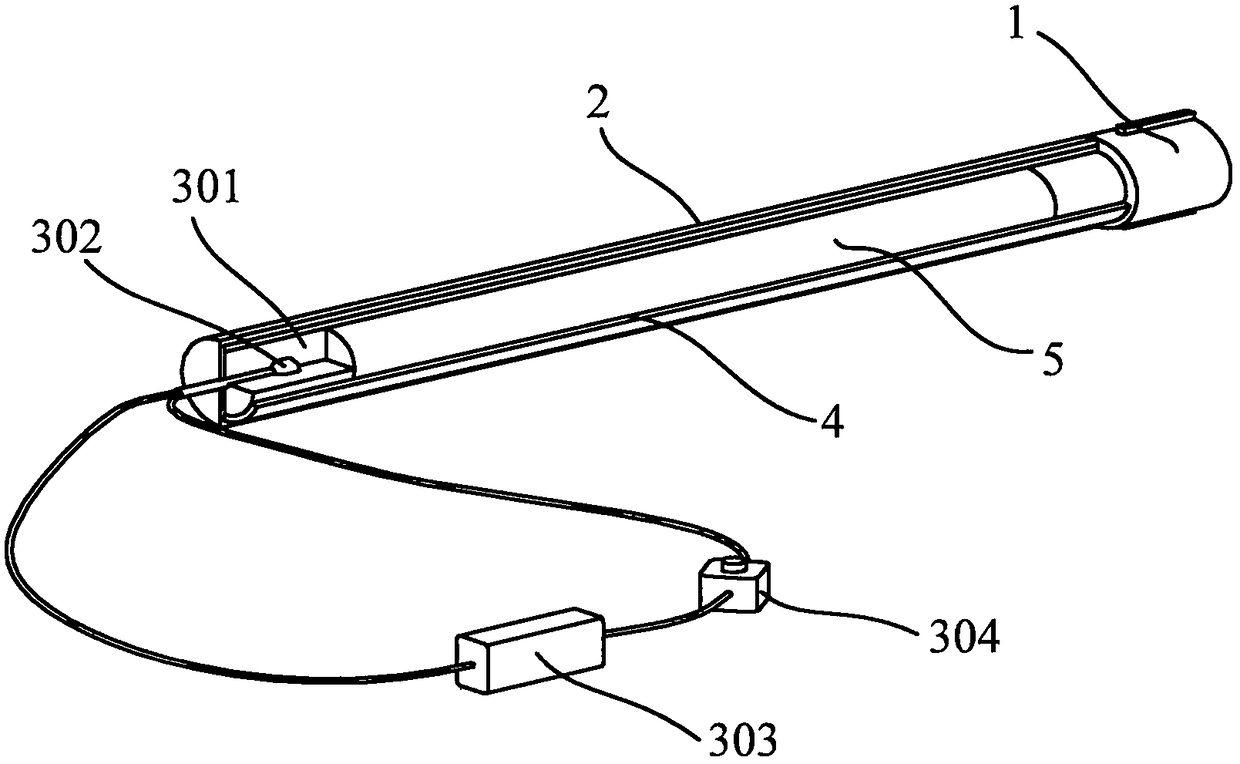

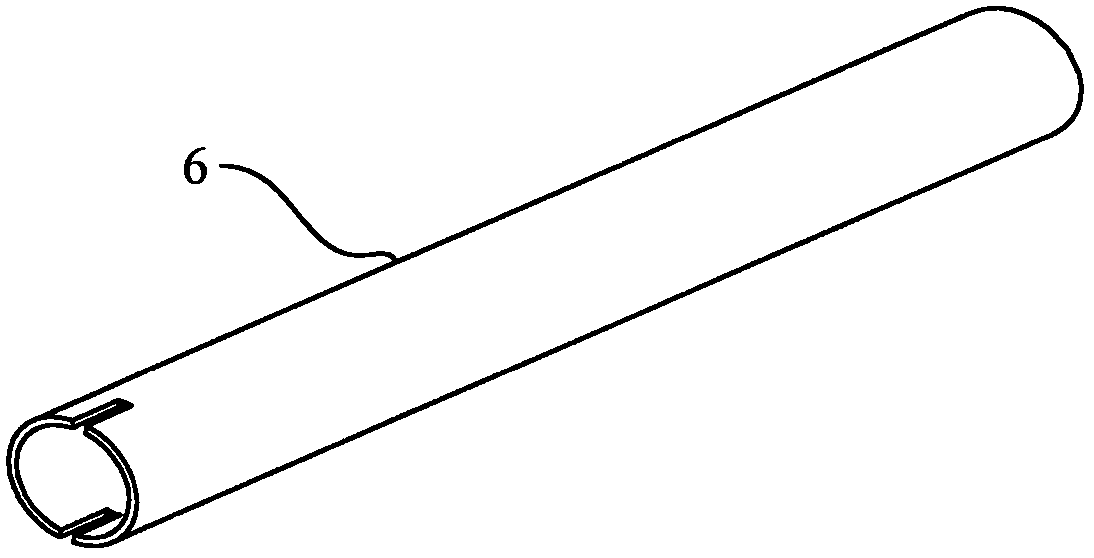

[0031] This embodiment provides an underwater emergency welding method for performing wet electroless welding on a 5mm thick Q235 steel plate. The welding material used is a special electrode for underwater electroless welding. For its structure, please refer to figure 1 with figure 2 .

[0032] Calculated by weight, Al powder 5g (-250 mesh), Mg powder 3g (-250 mesh), B powder 2g (-200 mesh), CuO powder 35g (-200 mesh), Fe 2 o 3 Powder 15g (-200 mesh), SiO 2 Powder 1.2g (-100 mesh), Cr 2 o 3 Powder 2g (-200 mesh), CaO powder 1.5g (-80 mesh), CaF 2 Powder 2g (-160 mesh), CaCO 3 Powder 1.5g (-160 mesh), W powder 1g (-200 mesh), CrFe powder 2g (-80 mesh), MnFe powder 1.5g (-80 mesh), TiFe powder 1.2g (-80 mesh), KNO 3 1g of powder (-80 mesh), mixed evenly in a three-dimensional mixer, baked at 200°C for 2 hours, pressurized and formed on a paper shell 4 with a diameter of 16mm and a length of 160mm, with a plastic or steel cylindrical plug 1 installed at one end , form ...

Embodiment 2

[0036] This embodiment provides an underwater emergency welding method for performing wet electroless welding on a 3 mm thick E32 marine structural steel plate. The welding material used is a special electrode for underwater electroless welding. For its structure, please refer to figure 1 with figure 2 .

[0037] Calculated by weight, Al powder 4.1g (-250 mesh), Mn powder 1.4g (-250 mesh), B powder 2.1g (-200 mesh), CuO powder 19.4g (-200 mesh), Fe 2 o 3 Powder 11g (-200 mesh), ZrO 2 Powder 4g (-200 mesh), SiO 2 Powder 1.2g (-100 mesh), Cr 2 o 3 Powder 1g (-200 mesh), CaO powder 0.8g (-80 mesh), NaF powder 1.2g (-160 mesh), CaCO 3 Powder 1g (-160 mesh), W powder 0.5g (-200 mesh), CrFe powder 0.5g (-80 mesh), MnFe powder 1.2g (-80 mesh), Ni powder 1g (-160 mesh), SiFe powder 0.8 g(-80 mesh), KNO 3 Powder 0.5g (-80 mesh), mix evenly in a three-dimensional mixer, bake at 200°C for 2 hours, press and form a paper shell with a diameter of 11mm and a length of 160mm with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com