Automatic packing machine

An automatic packaging machine and packaging bag technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of low bag opening success rate, increased production cost, and low production efficiency, and achieve high bag opening success rate and detection The effect of high precision and improved success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

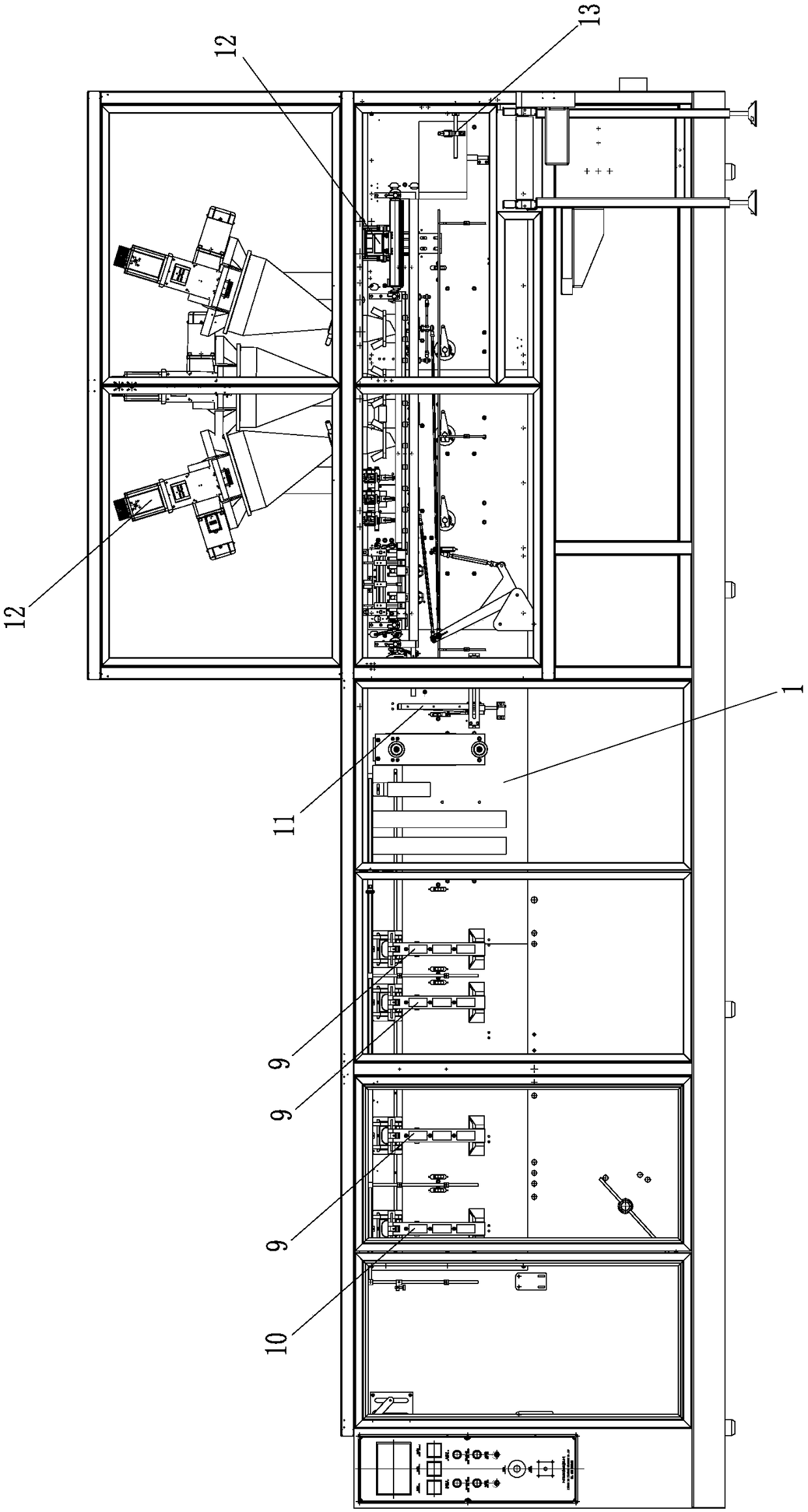

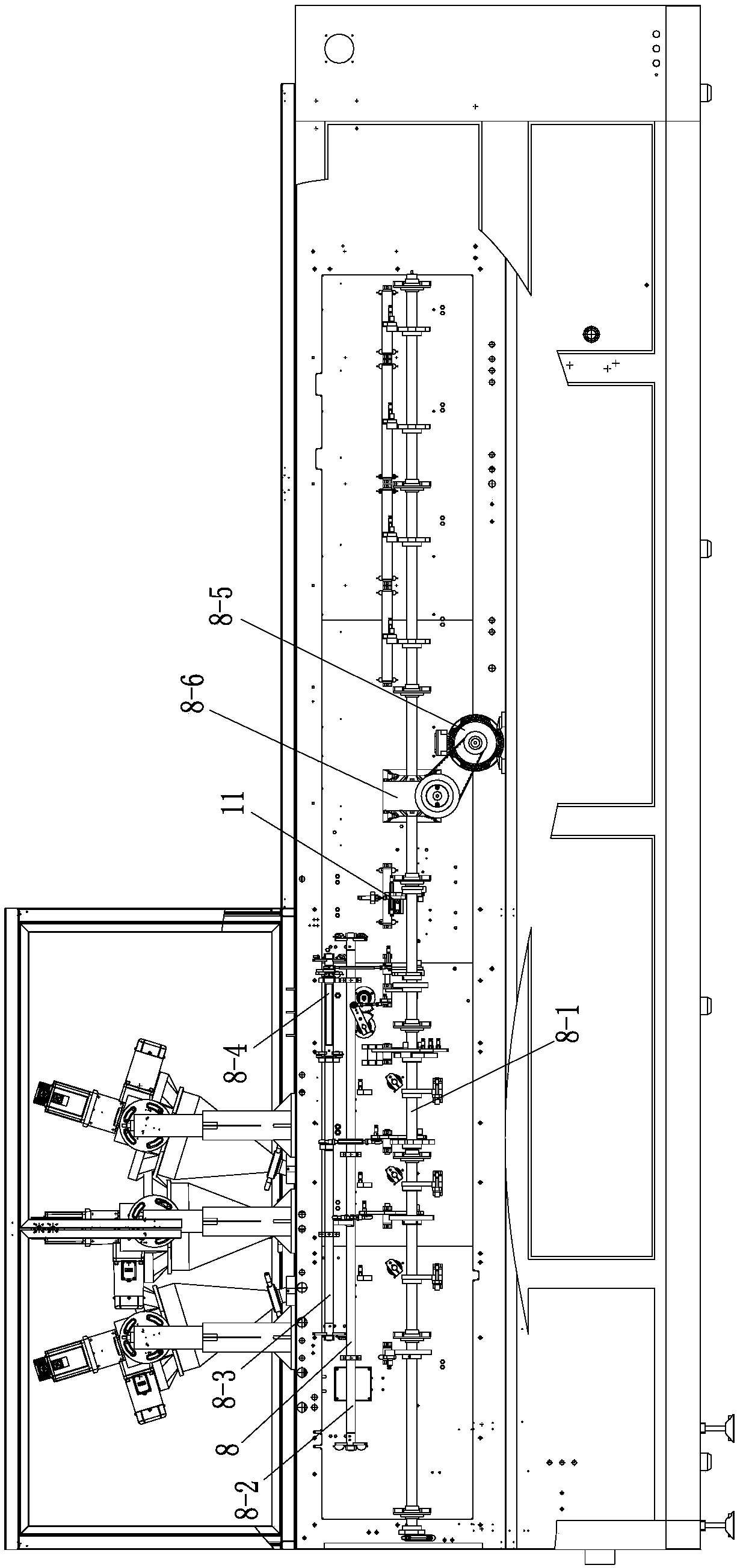

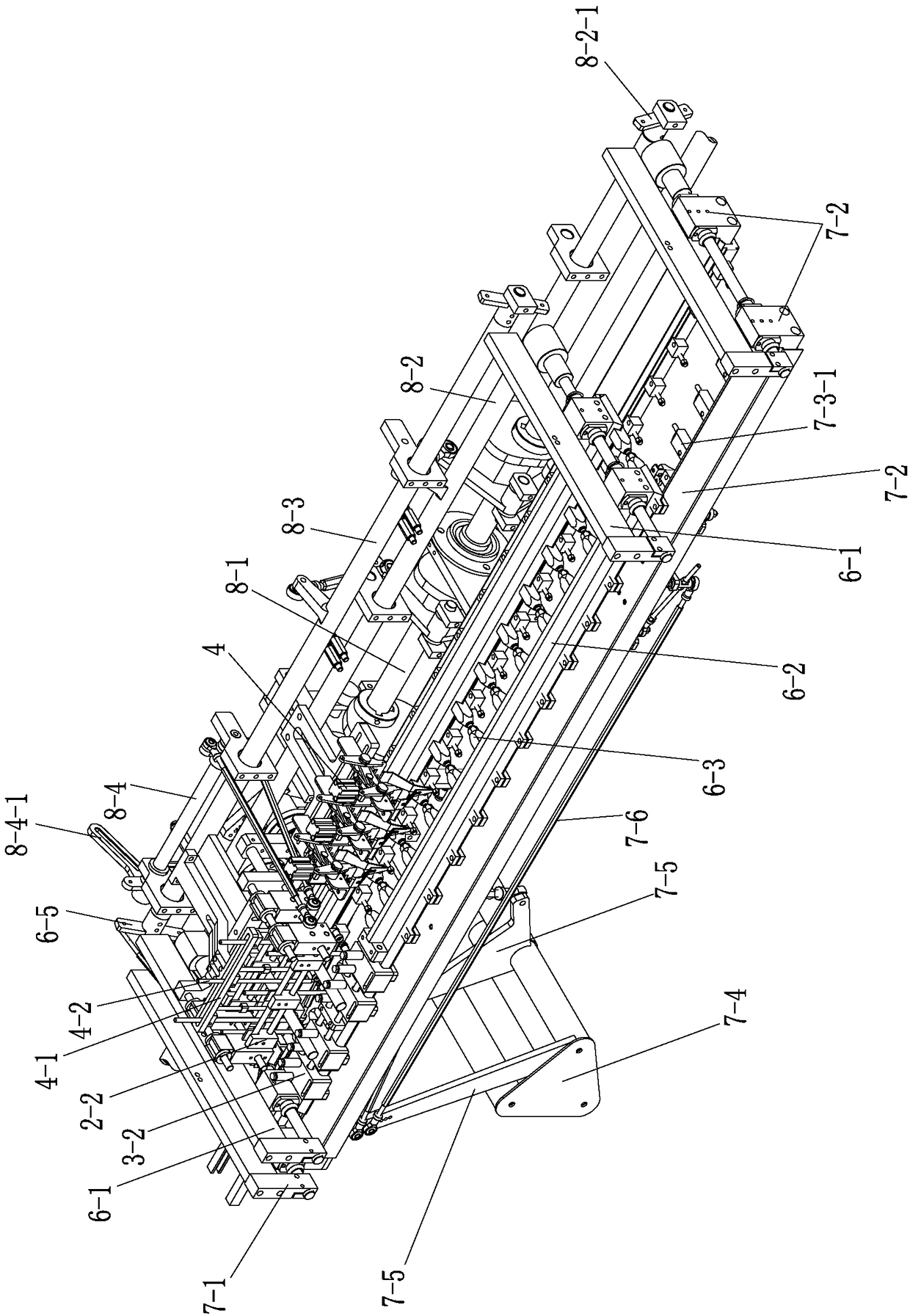

[0047] See Figure 1 to Figure 11 , the automatic packaging machine of this embodiment includes a frame 1 and a bag opening device arranged on the frame 1, a detection mechanism 5, a material clamping platform 6, a feeding trolley 7, a cam driving mechanism 8, a vertical sealing mechanism 9, a bottom seal Mechanism 10, bag cutting mechanism 11, filling mechanism 12, top sealing mechanism 13 and receiving mechanism 14.

[0048] The feeding trolley 7 grips the packaging bag and transfers the packaging bag to the middle part of the clamping platform 6 corresponding to the position of the processing station. The bag opening device is arranged on one side of the material clamping platform 6, and is used to open the mouth of the packaging bag. The clamping platform 6 is arranged on the top of the feeding trolley 7, and the packaging bags clamped by the feeding trolley 7 are clamped by two parallel clamping components moving towards each other. The cam driving mechanism 8 drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com