Thermoplastic resin composition and molding product thereof

A technology of resin composition and plasticity, which is applied in the field of thermoplastic resin composition and molded products, and can solve the problems of poor compatibility and reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

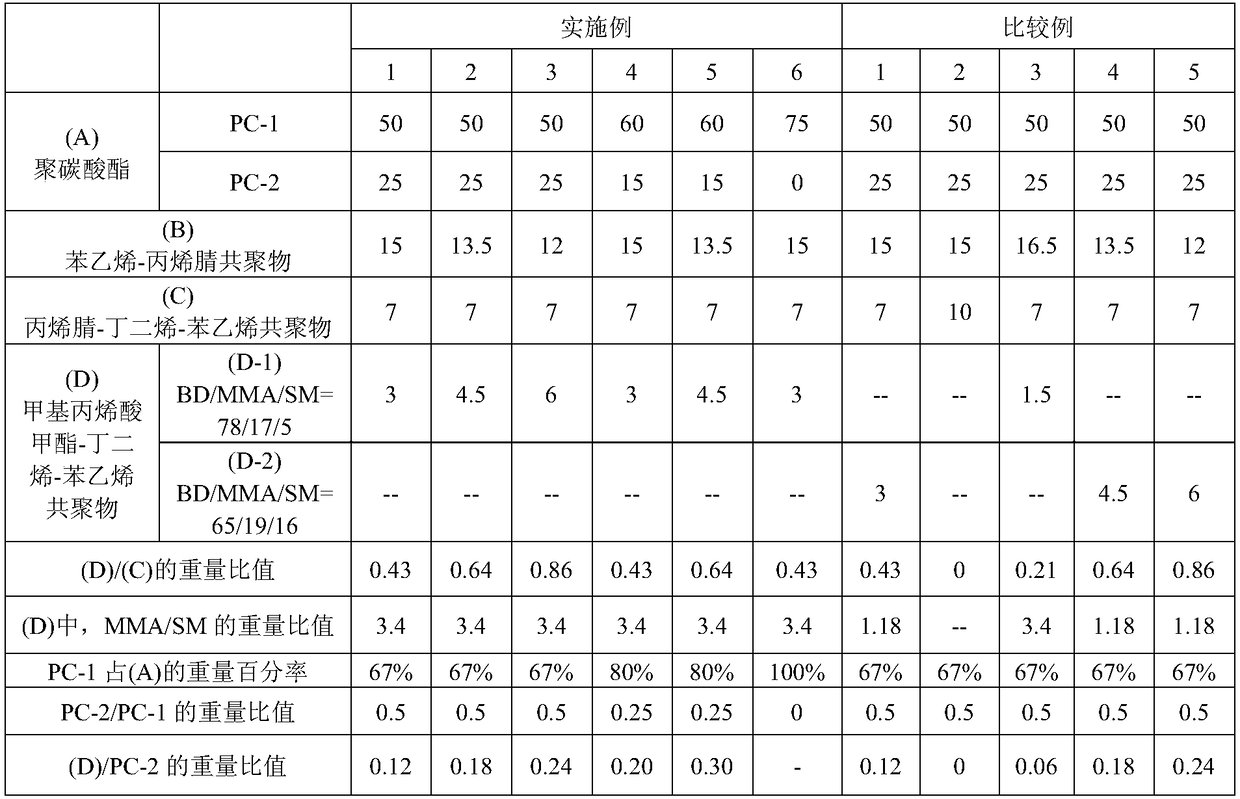

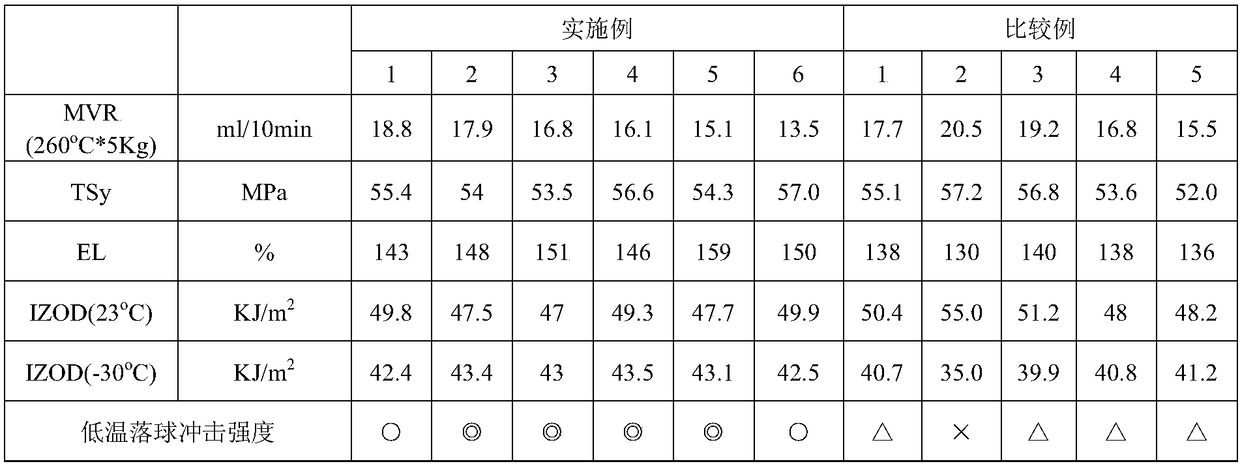

Examples

preparation example Construction

[0024] The polymerization method of styrene-acrylonitrile copolymer can adopt block polymerization method, solution polymerization method, suspension polymerization method, emulsification polymerization method, etc., among which block polymerization method or solution polymerization method is preferred. In addition, the method for preparing the styrene-acrylonitrile copolymer preferably includes performing polymerization using a reactor capable of continuous block or solution polymerization. The reactor includes: a columnar flow reactor, a completely mixed reactor (CSTR), or a tube reactor with static mixing elements, among which the completely mixed reactor is preferred. The number of reactors used may be one, or two or more reactors may be used in combination.

[0025] In one embodiment, the preparation method of the styrene-acrylonitrile copolymer is carried out by solution polymerization. The solvent used in the solution polymerization reaction is, for example, toluene, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com