Automobile dry cleaning pre-cleaning liquid and preparation method thereof

A technology for pre-washing liquid and automobiles, which is applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of high cleaning cost, pollute the environment, and take a long time, and achieves the elimination of body static electricity and a small amount of consumption. , The effect of saving cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

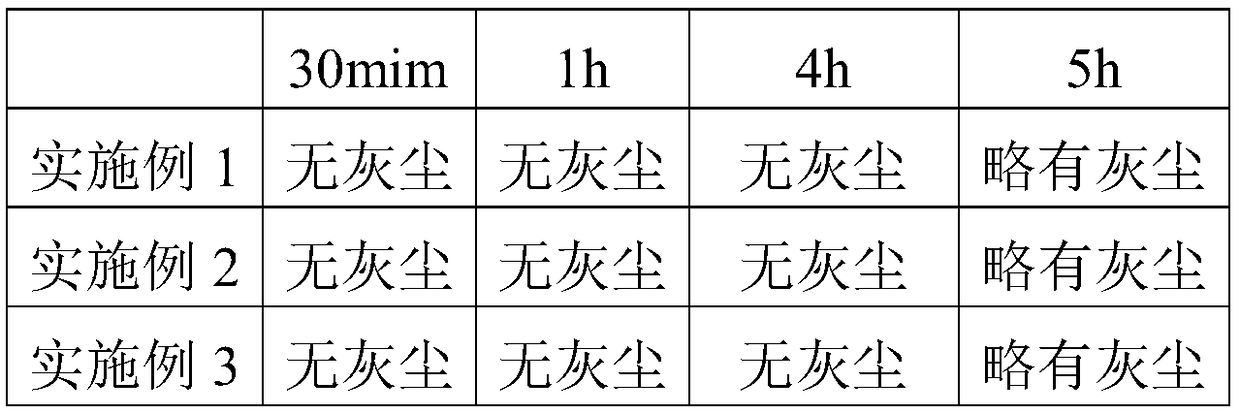

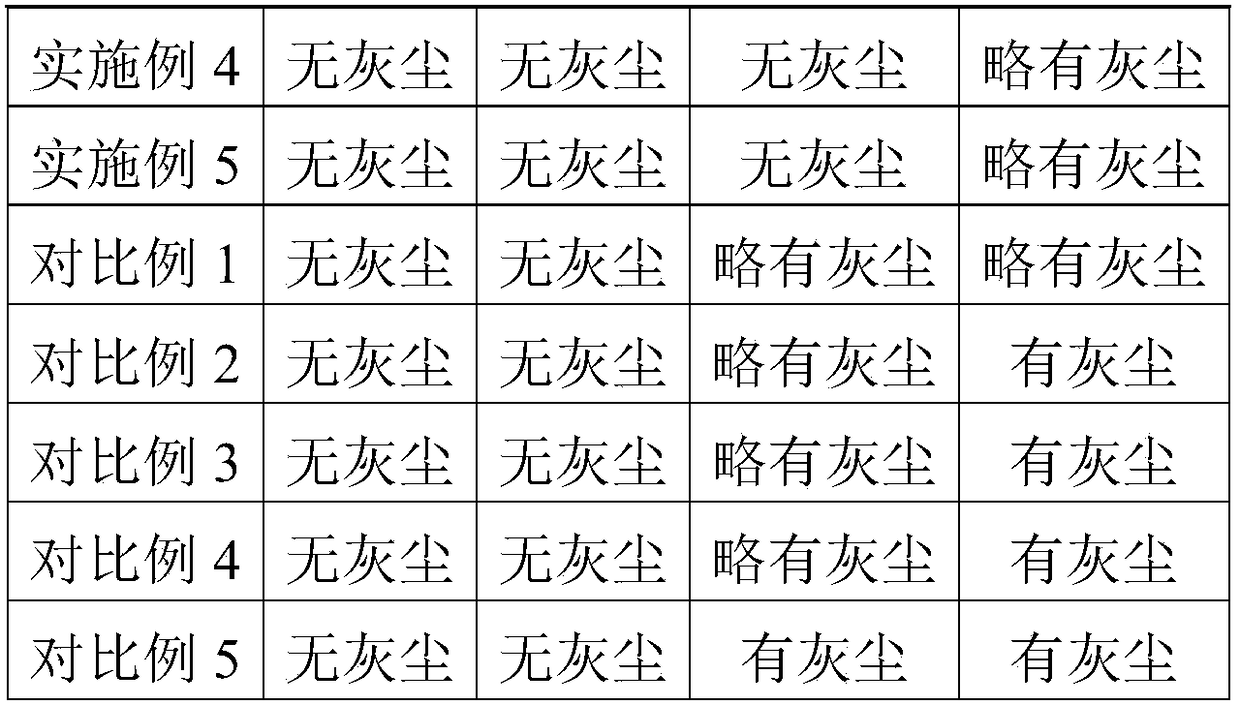

Examples

Embodiment 1

[0027] Cocamidopropyl betaine 69%, penetrant JFC 15%, bulking agent JF-804-50 7.99%, sodium alginate 5%, Kathon preservative 3%, essence 0.01%, put all raw materials into emulsification in proportion Carry out emulsification in the machine, the rotating speed of emulsification machine is 3000 revs, and the time is 20 minutes, gets dry-cleaning prewash.

Embodiment 2

[0029] Cocamidopropyl betaine 65%, penetrant JFC 14%, bulking agent JF-804-50 9.98%, sodium alginate 8%, Kathon preservative 3%, essence 0.02%, put all raw materials into emulsification in proportion Carry out emulsification in the machine, the rotating speed of emulsification machine is 3000 revs, and the time is 20 minutes, gets dry-cleaning prewash.

Embodiment 3

[0031] Cocamidopropyl betaine 72%, penetrant JFC 12%, bulking agent JF-804-50 8.99%, sodium alginate 4%, Kathon preservative 3%, essence 0.01%, put all raw materials into emulsification in proportion Carry out emulsification in the machine, the rotating speed of emulsification machine is 3000 revs, and the time is 20 minutes, gets dry-cleaning prewash.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com