Multi-orientation solar colored steel macromolecule rolling material composite roof system

A composite roof and polymer technology, applied in the direction of roof covering, roof, building roof, etc., can solve the problems of increased load, waste of building components, and impact on power generation income.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with embodiment.

[0046] A color steel composite roofing system suitable for multi-facing solar polymer coils, such as Figure 12 As shown, it includes thermal insulation layer 12.1, color steel tile cross purlin fixing screws 12.2, light steel structure cross purlin 12.3, light steel structure longitudinal purlin 12.4, polymer waterproof membrane 12.5, mouthpiece suitable for multi-facing roofs Type color coated steel tile module 12.6, general photovoltaic module fastener 12.7, general photovoltaic module 12.8, sealant 12.9, photovoltaic module connecting cable 12.10.

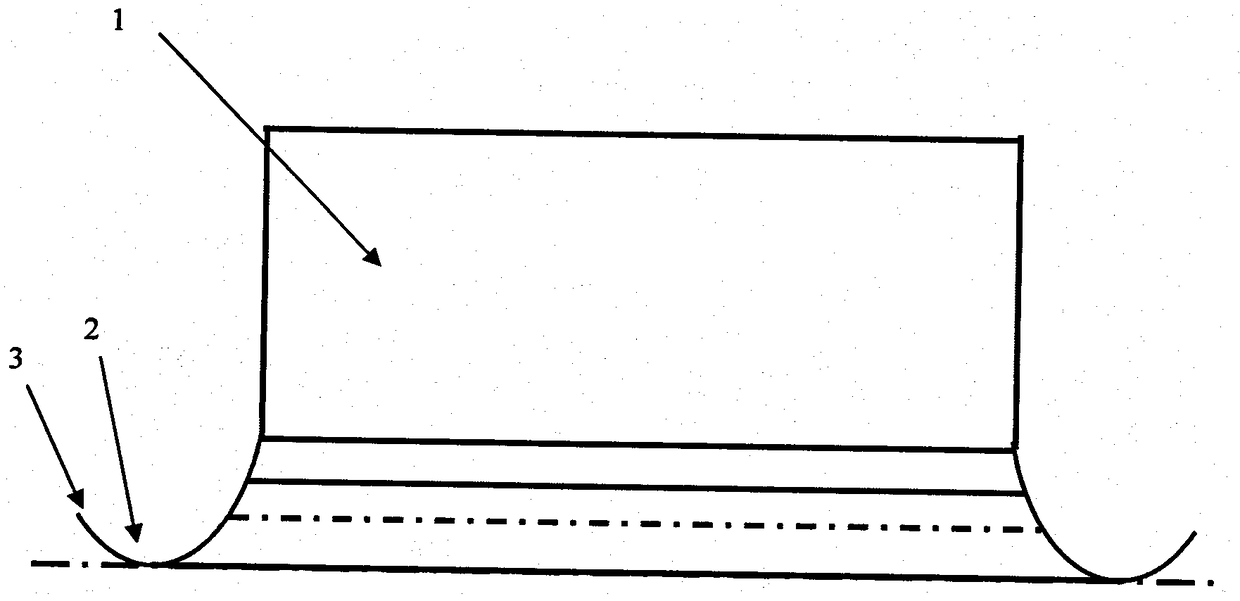

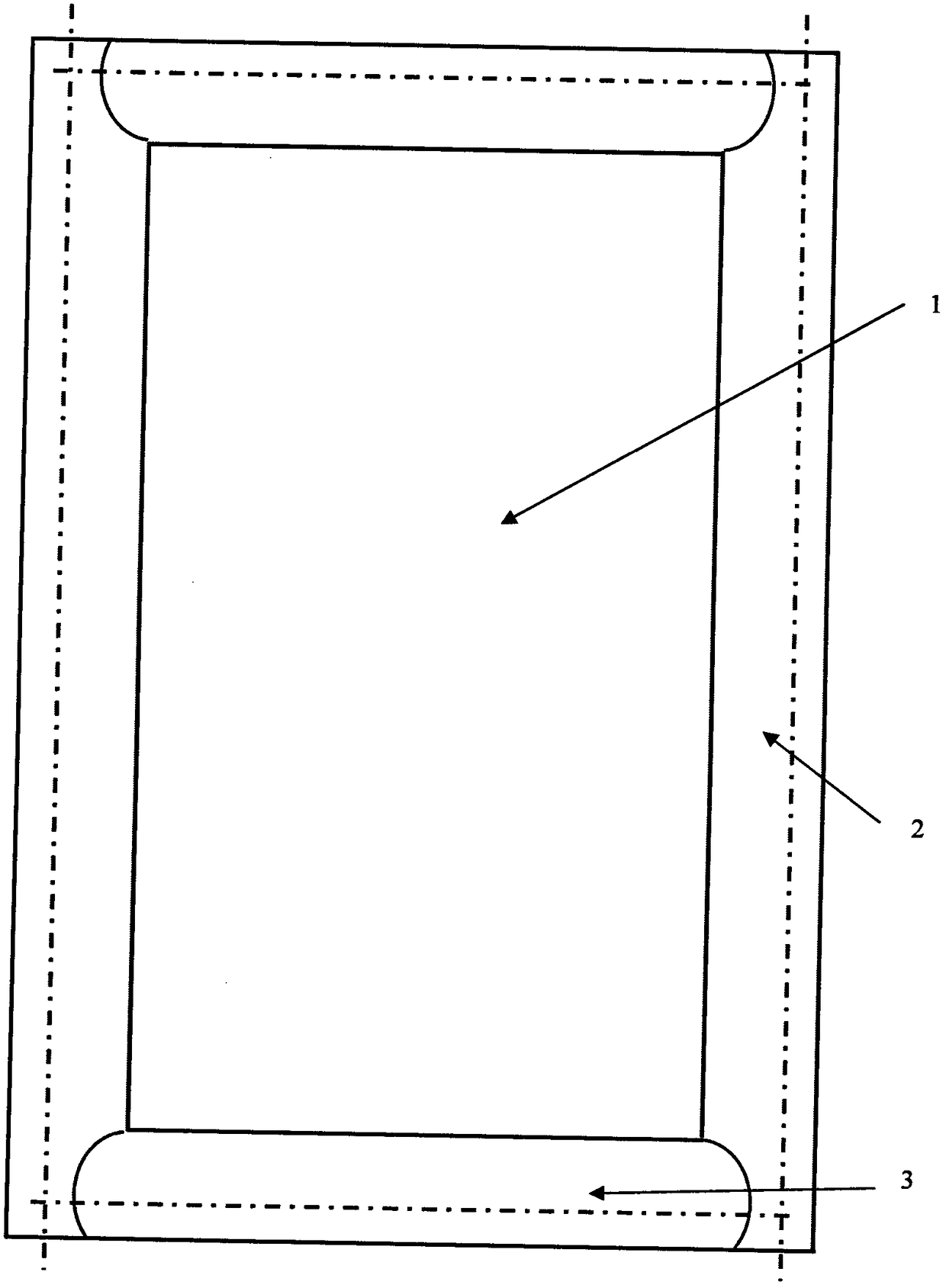

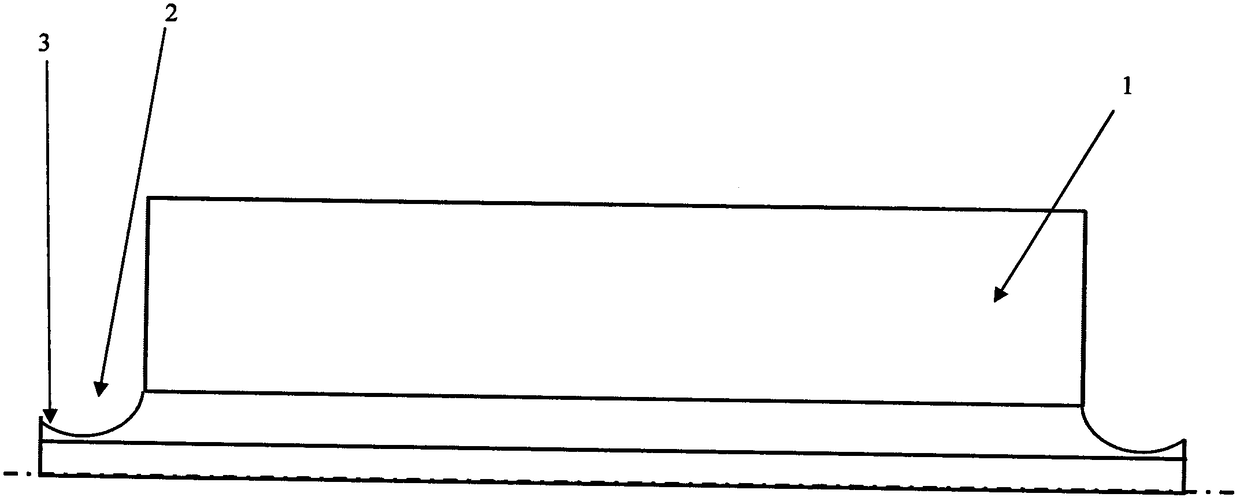

[0047] The cross-shaped color-coated steel tile module 12.6 suitable for multi-facing roofs, the detailed structure before pressing the top edge of the cross-shaped structure according to the orientation and inclination requirements of the project site is as follows figure 1 , figure 2 , image 3 As shown, it is obtained by stampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com