Solar photovoltaic-photothermal integrated pavement prefabricated part and power generation system

A technology of solar photovoltaic and prefabricated components, applied in the direction of photovoltaic thermoelectric hybrid power generation, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of aggravating the urban heat island effect, aggravating road rutting, and accelerating the thermal aging of asphalt pavement materials, so as to achieve simple construction procedures, The effect of reducing the pressure on the power grid and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

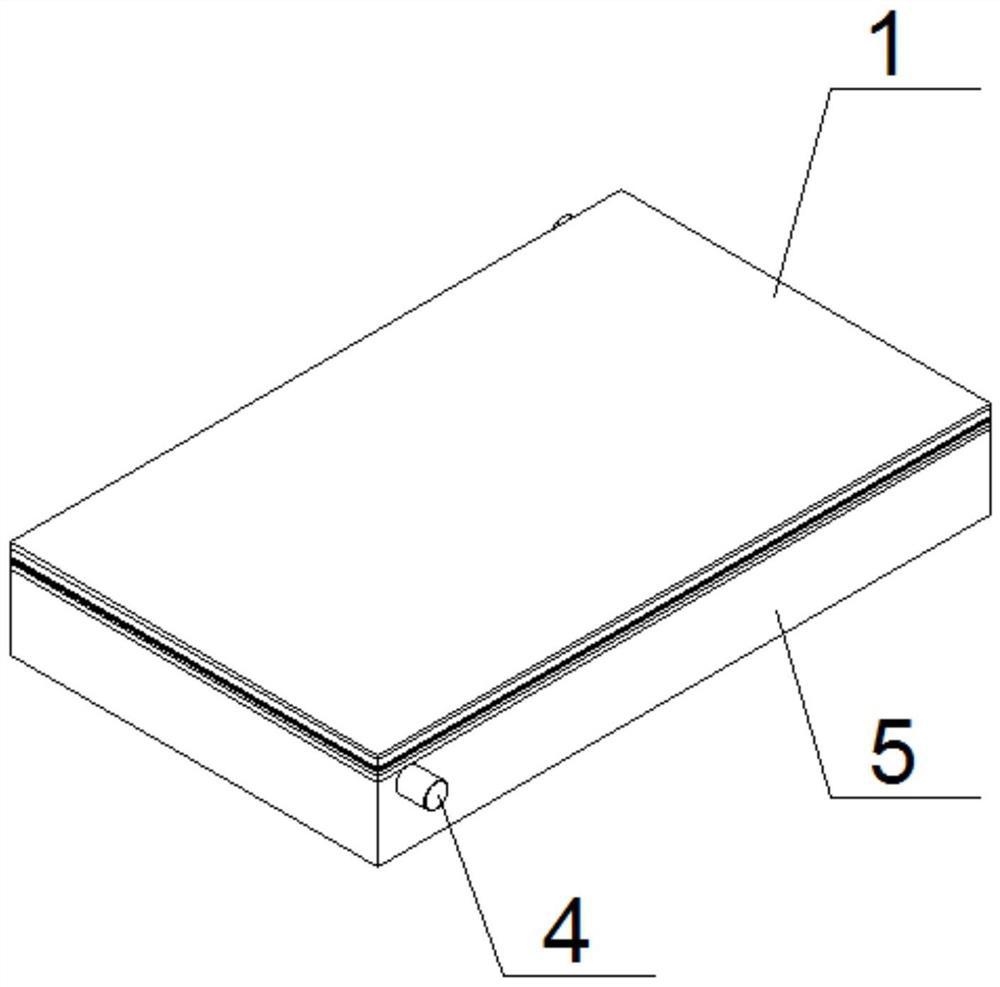

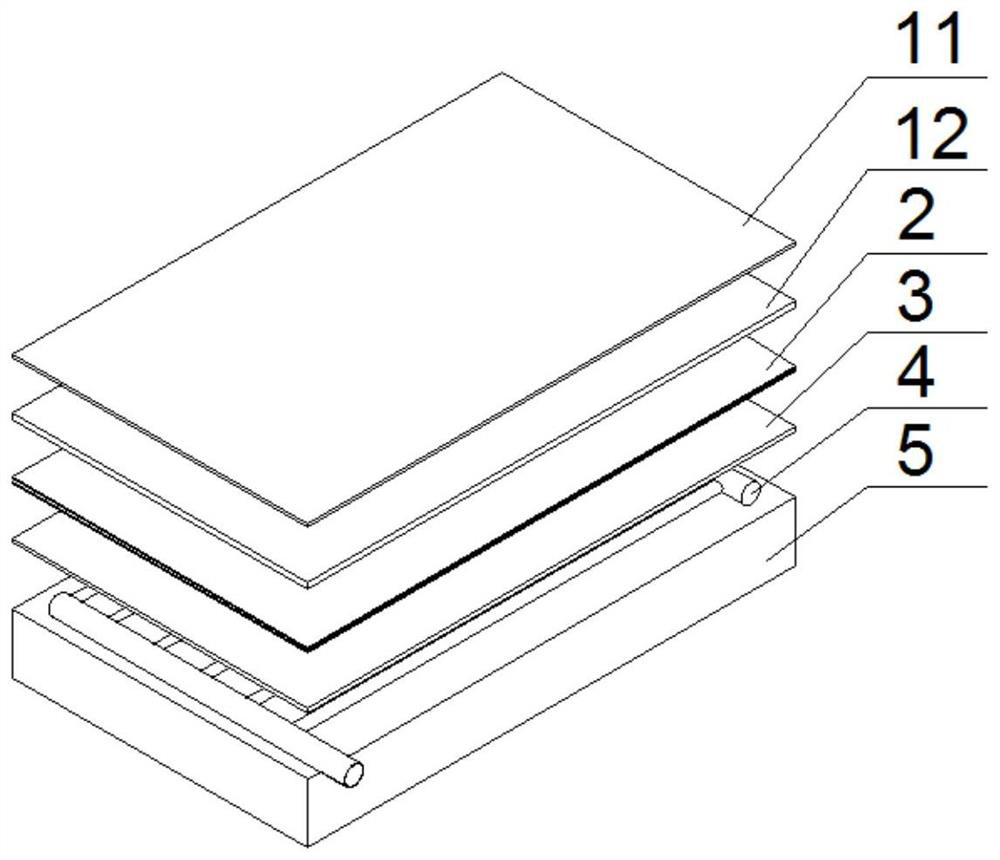

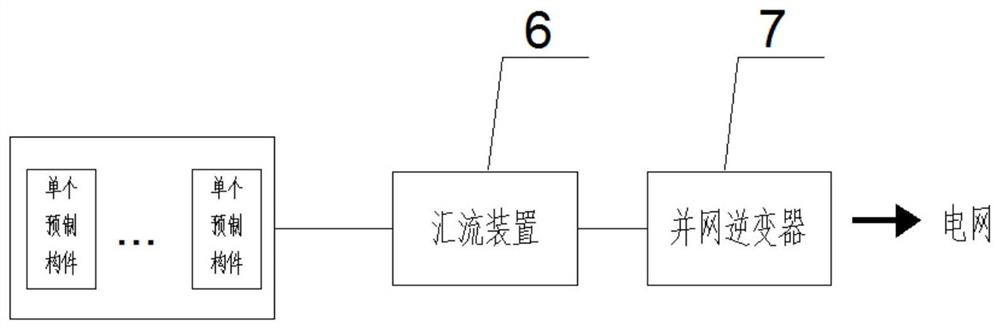

[0024] like figure 1 and figure 2 As shown, the present invention is a solar photovoltaic photothermal integrated pavement prefabricated component, including a solar photovoltaic collection structure and a photothermal conversion structure arranged from top to bottom.

[0025] The solar photovoltaic collection structure is used to collect sunlight energy and convert it into electrical energy, which includes a transparent wear-resistant panel 1, solar cells 2 and a thermally conductive backplane 3, and the solar cells 2 are encapsulated in the transparent wear-resistant panel 1 Between the heat-conducting back plate 3 and around the solar photovoltaic collection structure, transparent sealant is provided to ensure the overall airtightness and water resistance of the solar photovoltaic collection structure, and the appearance is beautiful and convenient for construction.

[0026] The transparent wear-resistant panel 1 should have good mechanical properties, anti-skid and wear-...

Embodiment 2

[0033]In this example, the tempered glass panel 12 has a size of 500mm*850mm and a thickness of 10mm, covered with a transparent anti-slip and wear-resistant layer 11 with a thickness of 5mm. The transparent anti-slip and wear-resistant layer 11 is made by mixing the following raw materials: 8- 80 parts by weight of 16-mesh toughened glass particles, 16 parts by weight of E-type epoxy resin (HJ2-741-72), and 4 parts by weight of curing agent (ethylenediamine). The thickness of the heat-conducting back plate 3 is 8 mm, and the material is aluminum with excellent heat-conducting properties. The solar cell 2 uses 15 monocrystalline silicon solar cells (3*5 arrangement), the size of each cell is 156mm*156mm, and the factory efficiency is 17.8%. Therefore, under the standard test state, the entire solar photovoltaic photothermal The output electric power of the integrated pavement prefabricated component is about 76W. 15 solar cells 2 cells are connected in series, and a transpare...

Embodiment 3

[0036] like Figure 4 As shown, in this example, the tempered glass panel 12 and the thermally conductive backplane 3 both have a size of 500mm*500mm and a thickness of 10mm, wherein the tempered glass panel 12 is covered with a transparent anti-skid and wear-resistant layer 11 with a thickness of 3mm. The transparent anti-slip and wear-resistant layer is made by mixing the following raw materials: 70 parts by weight of tempered glass particles of 8-16 mesh, 24 parts by weight of E-type epoxy resin (HJ2-741-72), and 6 parts by weight of curing agent (ethylenediamine) . The solar cell 2 adopts 9 polysilicon solar cells (3*3 layout), the size of each solar cell 2 is 156mm*156mm, and the factory efficiency is 16%. Therefore, under the standard test state, the whole solar photovoltaic light The output power of thermal integrated pavement prefabricated components is about 35W. Nine solar cells 2 are connected in series, and a transparent EVA film layer is added between the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com