Device and method for measuring heat conductivity coefficient of buffer/backfill material

A technology of thermal conductivity and measuring device, which is used in the field of thermal conductivity testing of buffer/backfill materials for geological disposal of high-level radioactive waste, and achieves the effects of high precision, convenient measurement and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

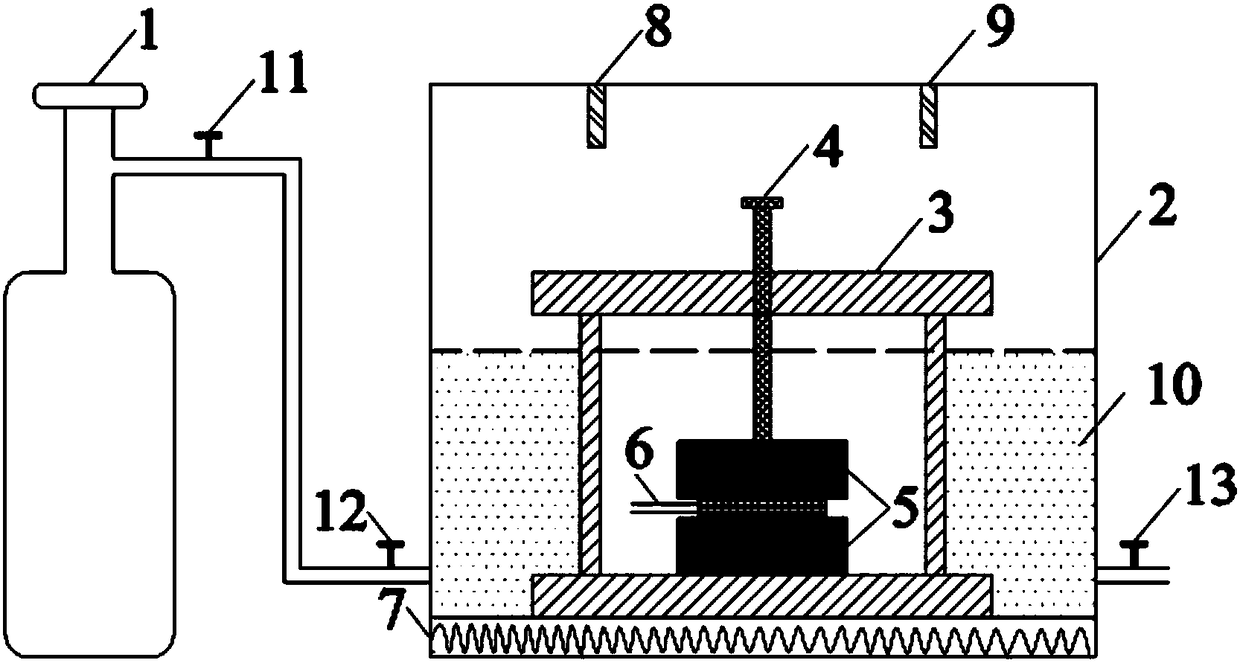

[0045] Step 1. Sample preparation

[0046] (1.1) Weigh the mass of bentonite and additives according to a certain ratio (9:1), prepare test samples with different water content (10%) by spray method, and keep them sealed for at least 48 hours to ensure their uniformity;

[0047] (1.2) According to the predetermined dry density (1.7g / cm 3 ) And volume (Φ30mm×10mm), calculate and weigh the corresponding mass of bentonite and additives;

[0048] (1.3) Load the weighed bentonite and additives into the pressing mold, start the press for sample pressing, record the mass and volume of the test sample after demolding, and quickly put it into a sealed bag for later use;

[0049] Step 2. Sample installation

[0050] (2.1) Clamp the test probe 6 between the two test samples 5, put it into the sample holder 3, and tighten the screw 4 to make the test sample 5 and the test probe 6 closely contact;

[0051] (2.2) Put the sample rack 3 with the sample installed into the test box 2, pour the liquid 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com