Laser deicing device

A laser and measurement device technology, applied in overhead installation, cable installation, electrical components, etc., can solve problems such as insufficient intelligence and automation, low work efficiency, and poor real-time feedback, so as to reduce work safety risks and improve work efficiency , the effect of high level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

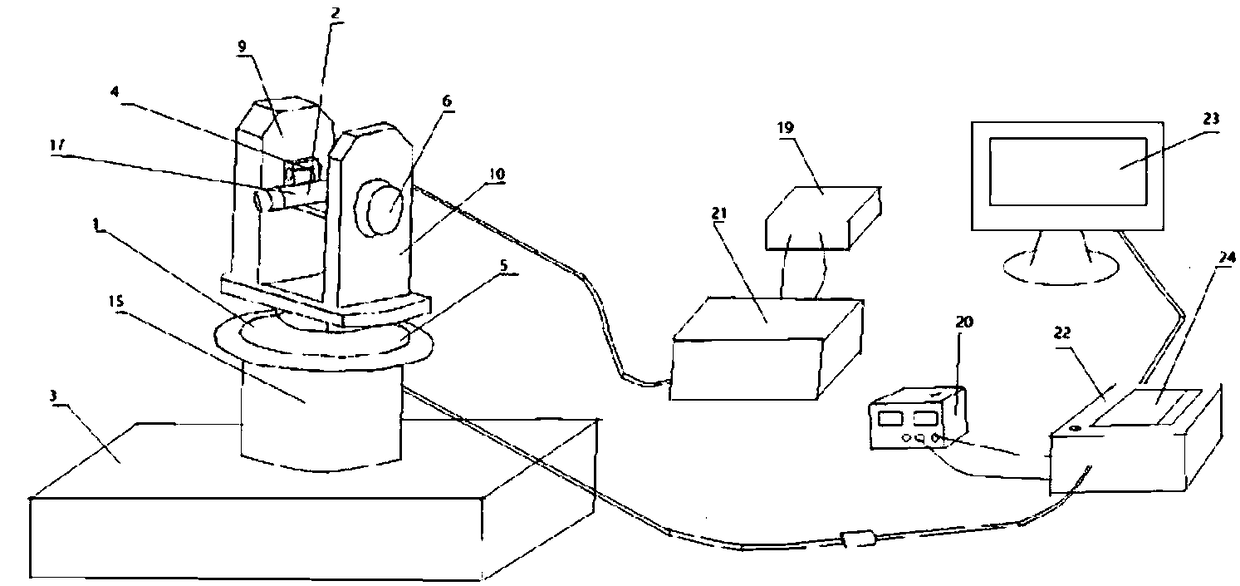

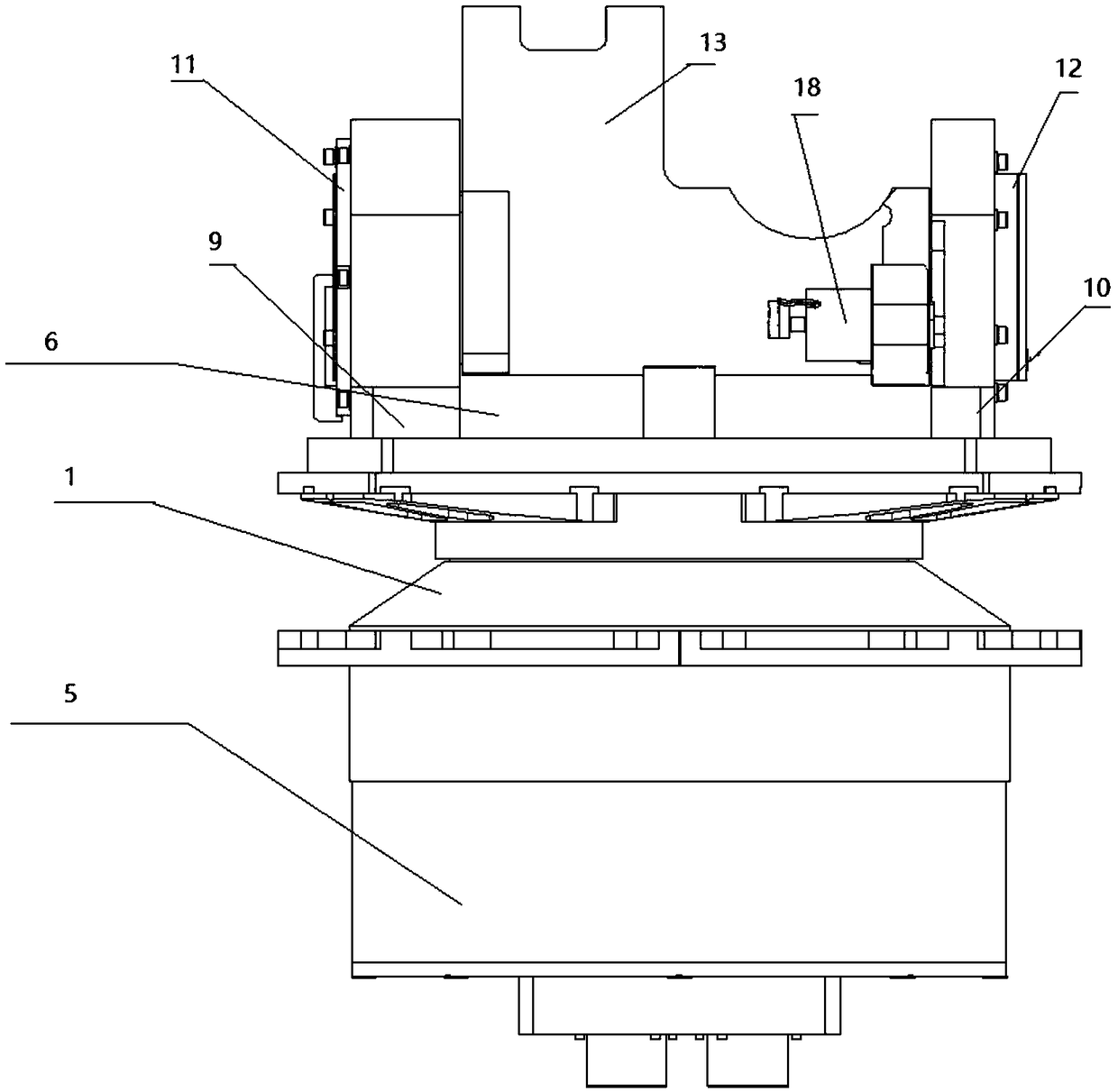

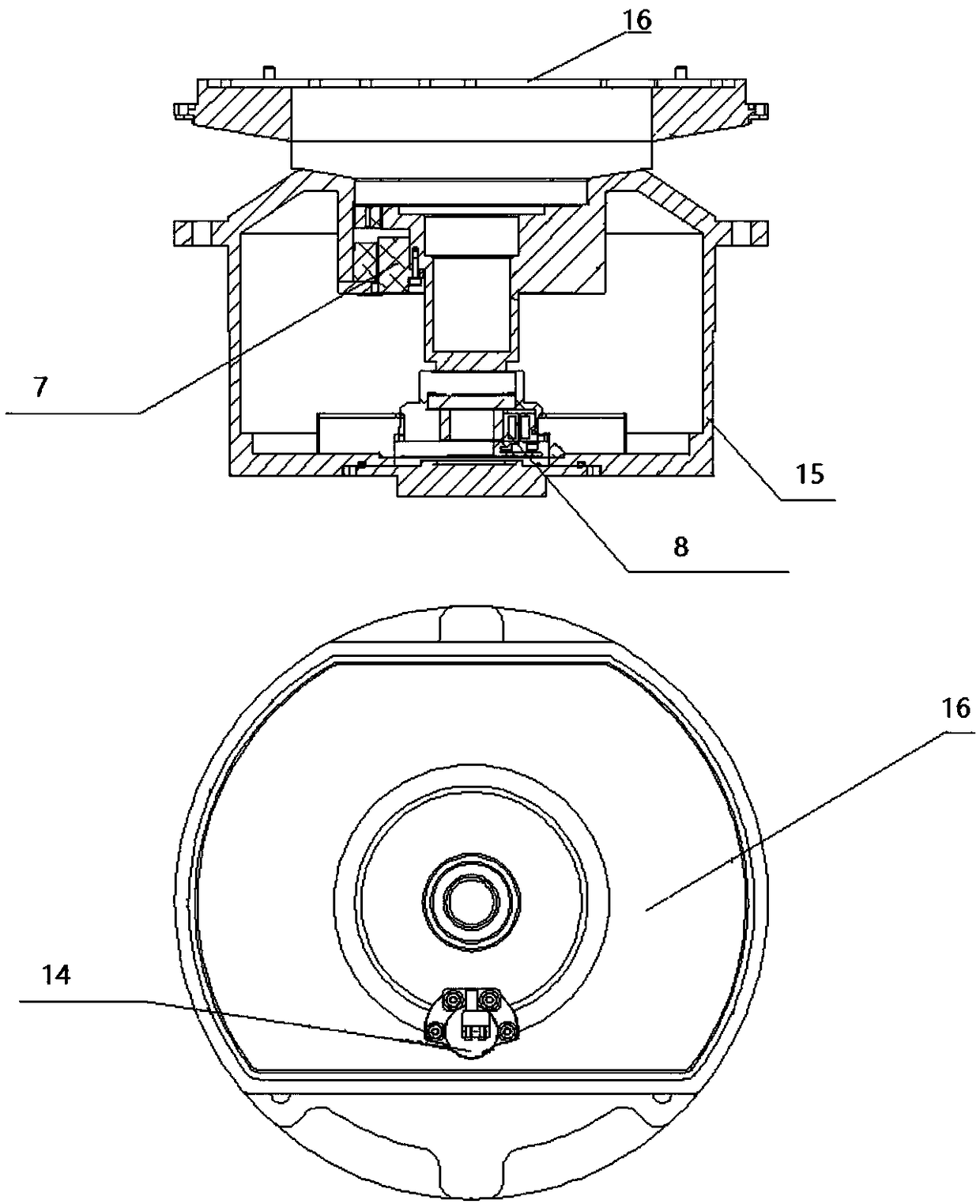

[0016] Such as figure 1 As shown, a laser deicing device of the present invention includes a turntable 1, a laser component 2, a base 3, a power supply system, an input and output device, a control system and a visual sensor module 4, wherein the turntable 1 includes an azimuth component 5 and a pitch component 6. The azimuth component 5 is installed above the base 3, including the azimuth torque motor 7, the azimuth angle measuring device 8, the azimuth limit lock parts 14, the azimuth base 15 and the azimuth bracket 16; the pitch component 6 is installed on the azimuth component 5 above, including bearing seat one 9, bearing seat two 10, pitching moment motor 11, pitching angle measuring device 12, connecting part 13, pitching limit lock parts 18; the connecting part of pitching part 6 is installed in part of the laser part 2 13 ; the visual sensor module 4 is installed on the coupling part 13 of the pitching part 6 .

[0017] In the control system, the industrial computer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com