Brush grinding head for a grinding machine

A technology of grinding head and grinding machine, which is applied in the direction of portable grinding bed, wheel with flexible working part, grinding machine, etc. It can solve the problems of wood rot and other problems, and achieve the effects of simplifying manufacturing, improving surface quality and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

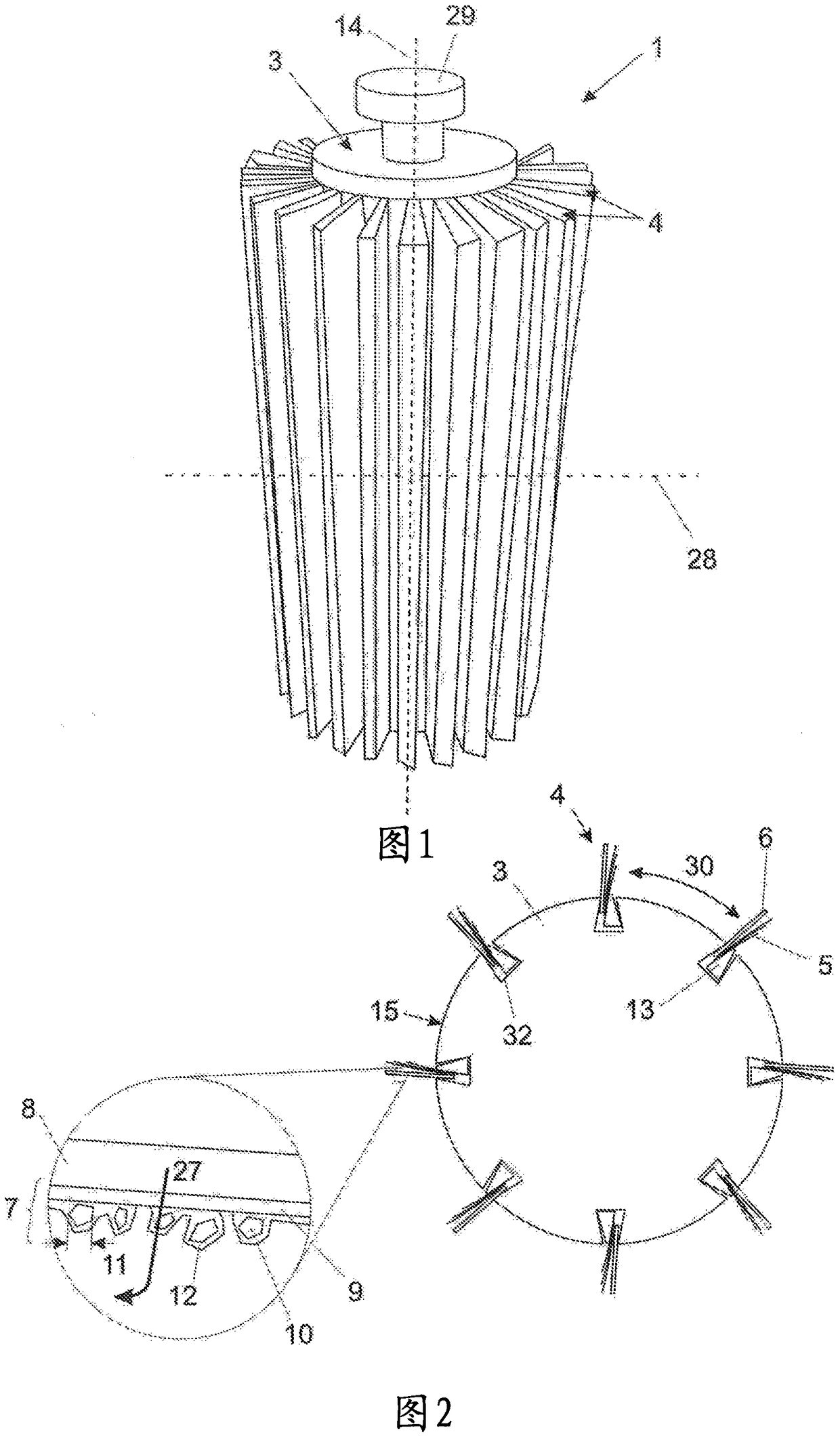

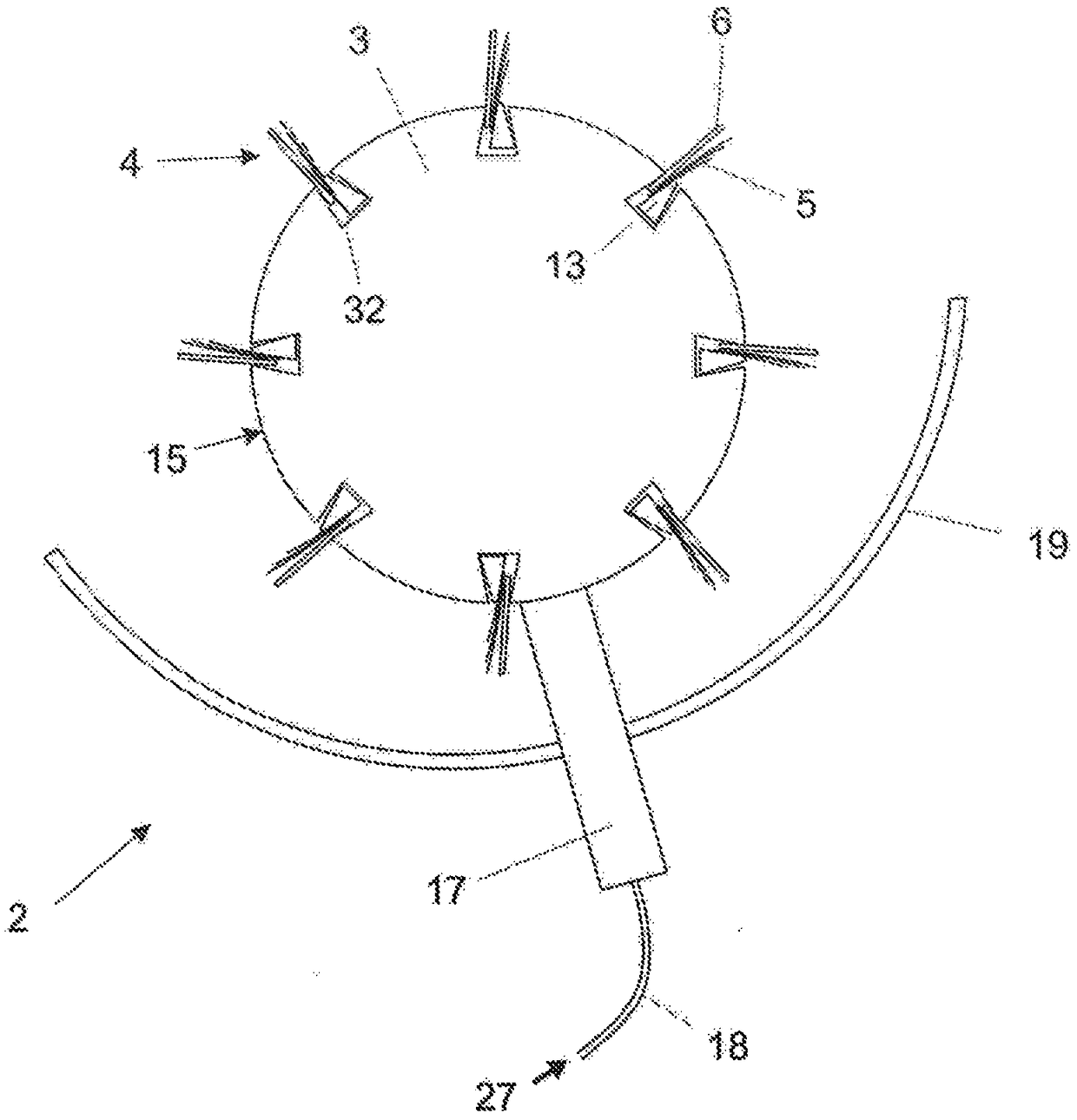

[0031] figure 1 A brush grinding head 1 for a grinding machine 2 is shown, which comprises a roller-shaped carrier 3 , wherein the carrier 3 is designed in the present case to be rotationally symmetrical.

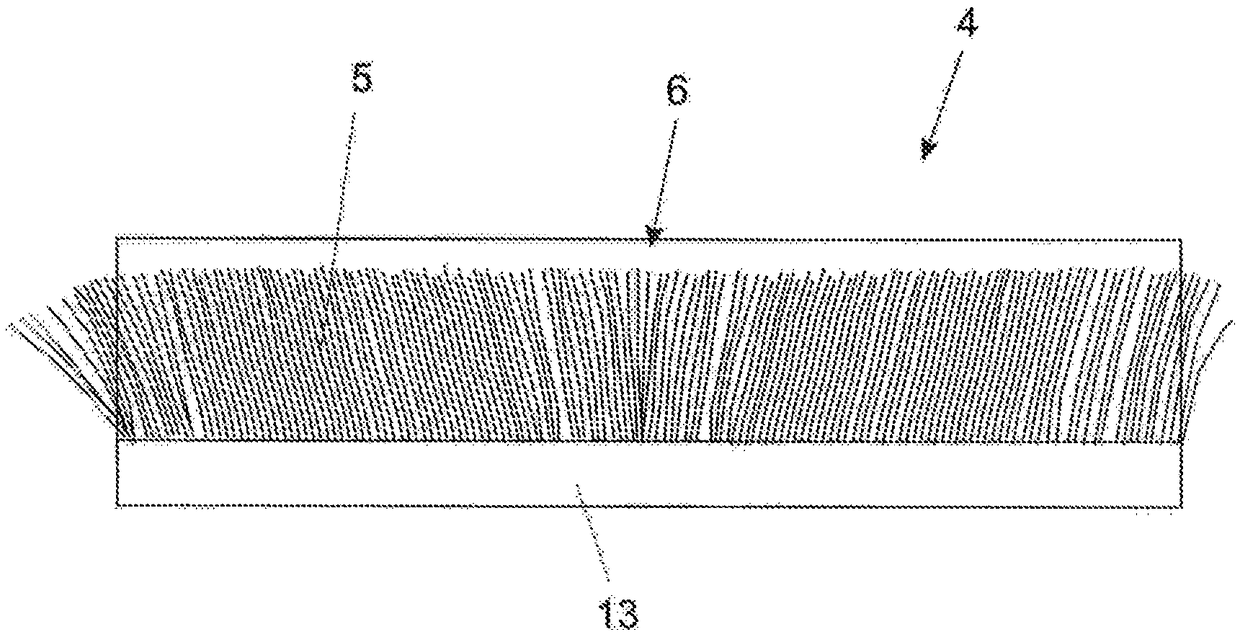

[0032] The brush grinding head 1 also includes a grinding plate 4 which is arranged on the support 3 on the circumferential side. Brush grinding head 1 has an axis of rotation 14 . The grinding disc 4 is arranged on the carrier 3 parallel to this axis of rotation 14 . Alternatively, an arrangement in which the grinding disc 4 is oriented obliquely to the axis of rotation 14 is also conceivable. In this case, the grinding disc 4 itself is bent around the radius of the carrier 3 and is arranged helically on the carrier 3 as a whole.

[0033] The carrier 3 has projections 29 which are arranged on both end sides of the carrier 3 and with which the brush grinding head 1 can be inserted into the grinder 2 .

[0034] The drive of the brush grinding head 1 can also be realized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com