A stator for an electric motor and a method of manufacturing a stator

A motor and stator technology, which is applied in the manufacture of stator/rotor bodies, motor generators, and motor components, etc., can solve problems such as the reduction of motor efficiency and power capability, and achieve the effect of improving retention force and structural integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

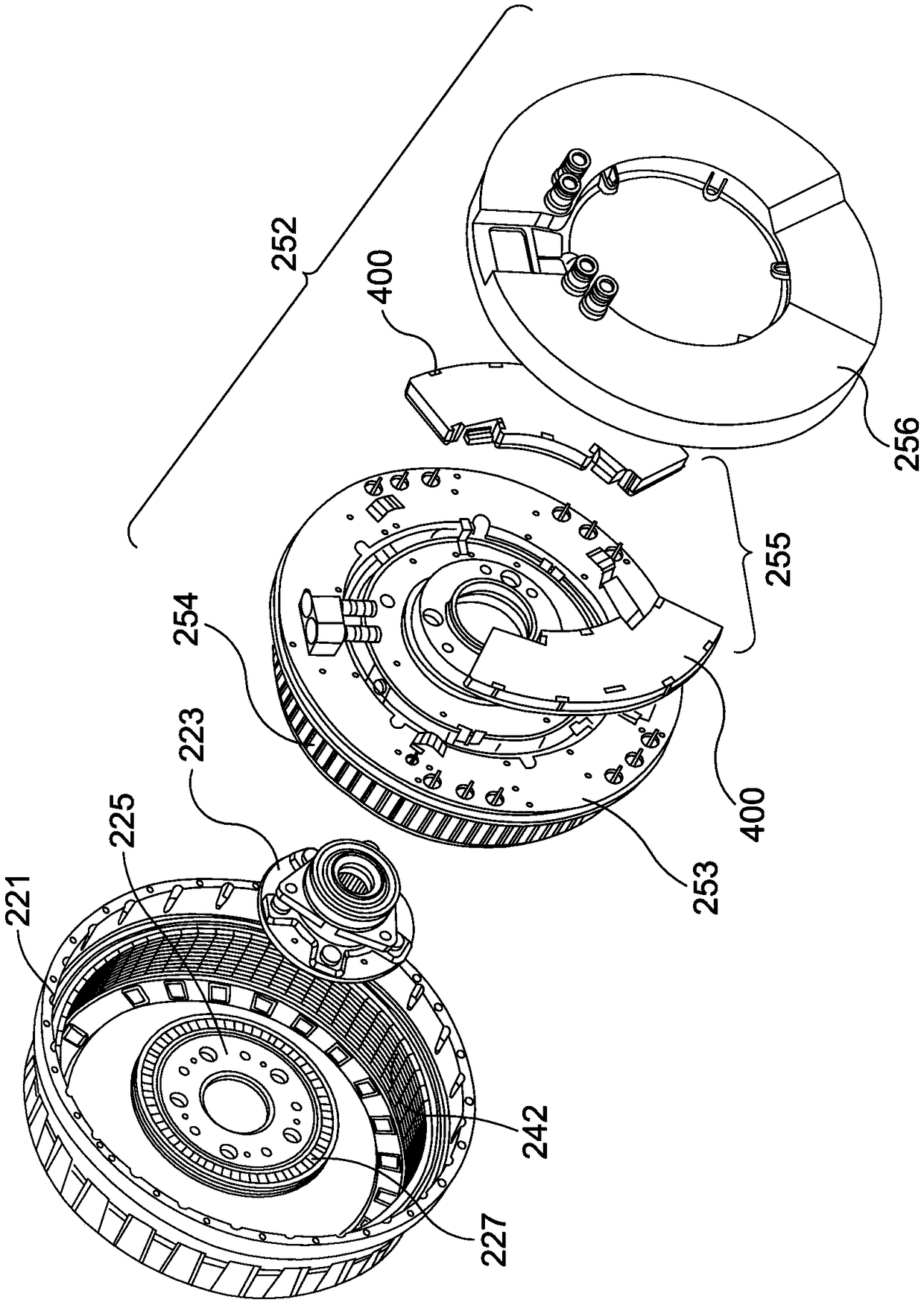

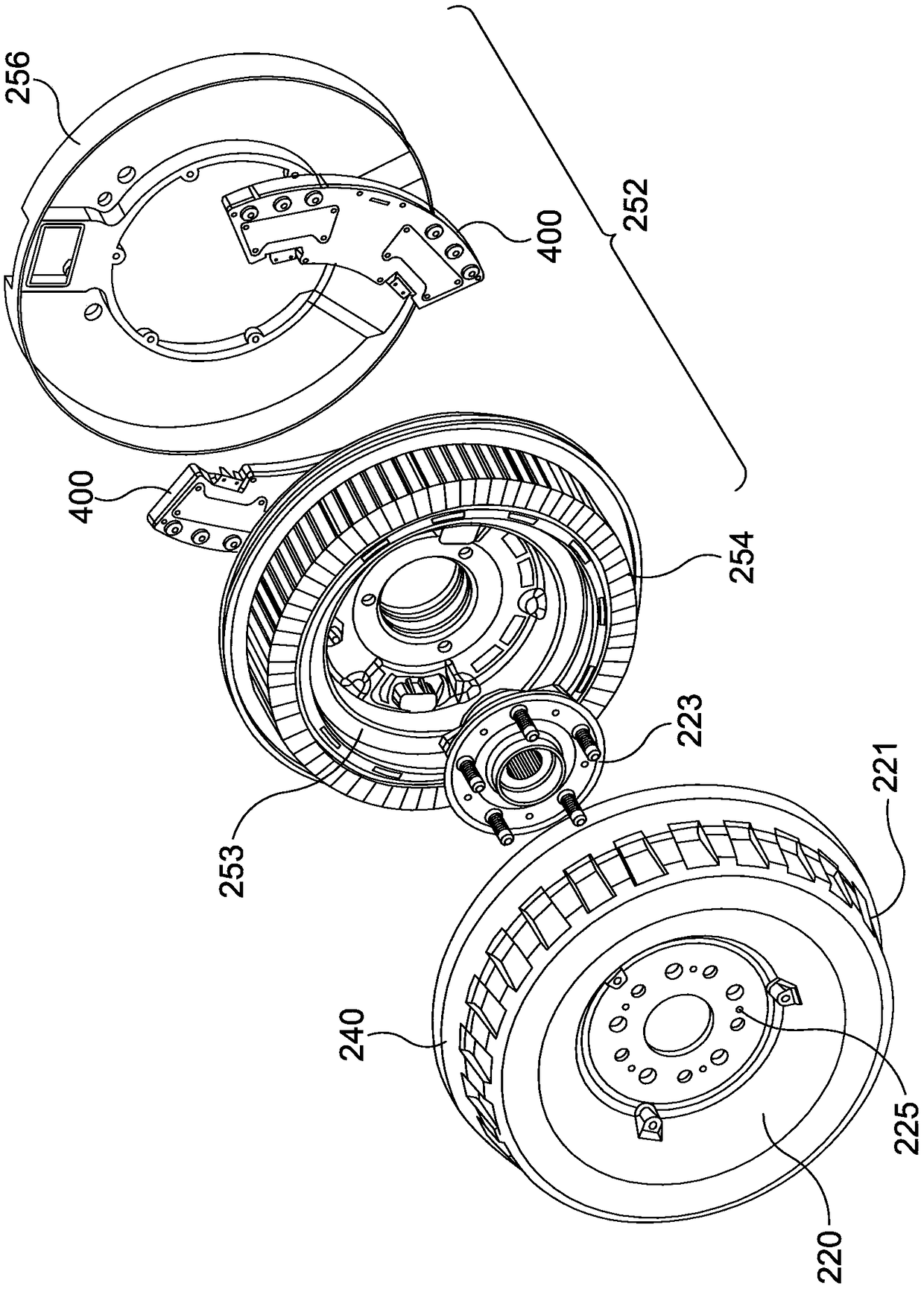

[0025] figure 1 with figure 2 Shown is an electric motor assembly according to the invention and having an electric motor with a stator, wherein the electric motor assembly includes built-in electronics and is configured to function as an in-wheel or in-wheel motor arranged to be housed within a wheel. However, the invention can be incorporated into any form of electric motor. The electric motor can also be configured as a generator.

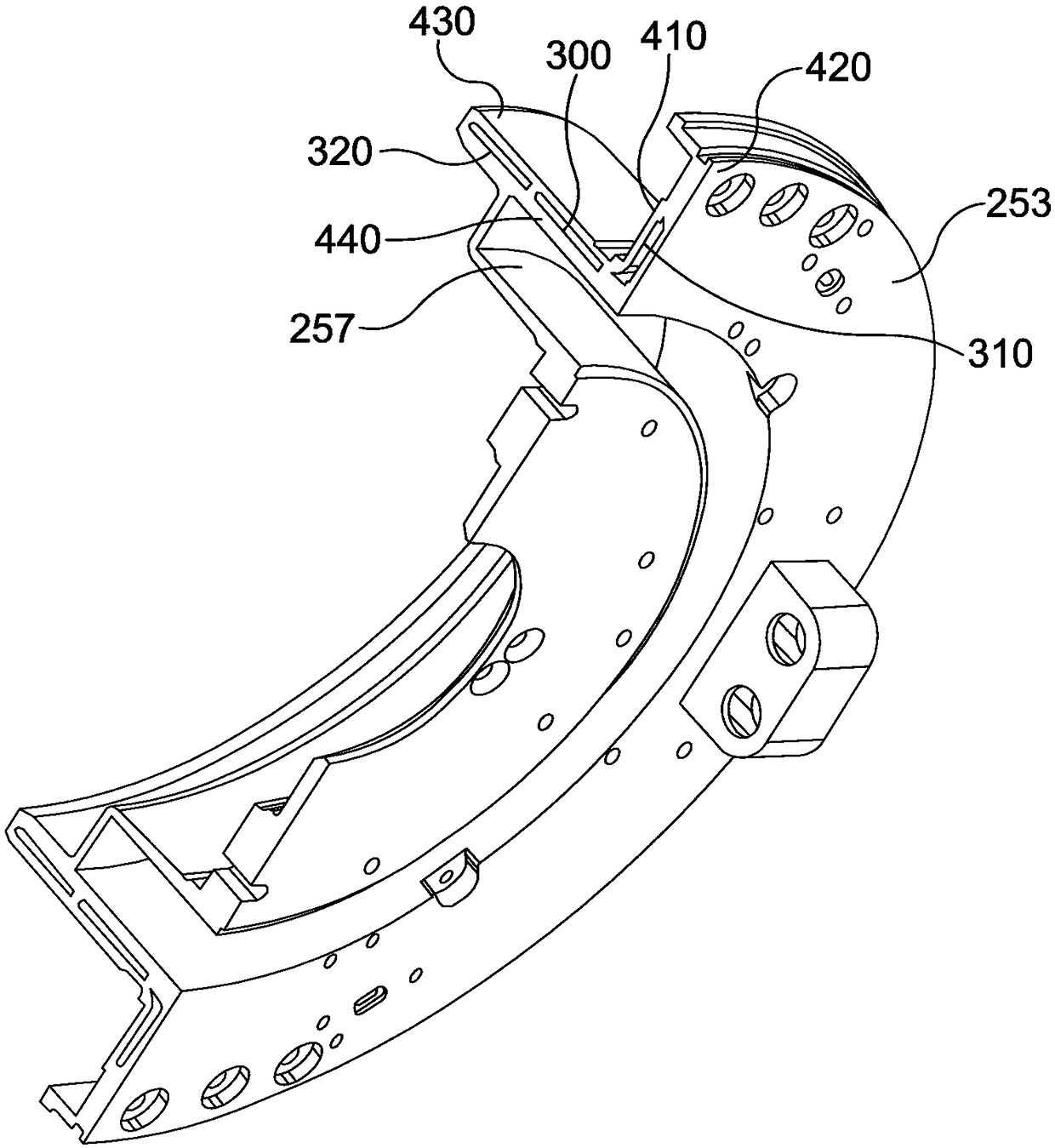

[0026] For the purposes of this embodiment, if figure 1 with 2 As shown, the in-wheel motor includes a stator assembly 252 and a rotor assembly 240 . The stator assembly 252 includes a heat sink 253 with cooling channels, a laminated back iron (not shown), multiple coils 254, an electronics module 255 mounted on the rear of the stator for driving the coils, and capacitors (not shown) as described below, The capacitor is mounted on the stator in a recess 257 formed at the rear of the stator. In a preferred embodiment, the capacitor is a ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com