White tea extract with high tea polyphenol content

A technology of white tea extract and tea polyphenols, applied in tea extraction, pre-extraction tea treatment, tea, etc., to achieve the effect of improving extraction rate and promoting dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

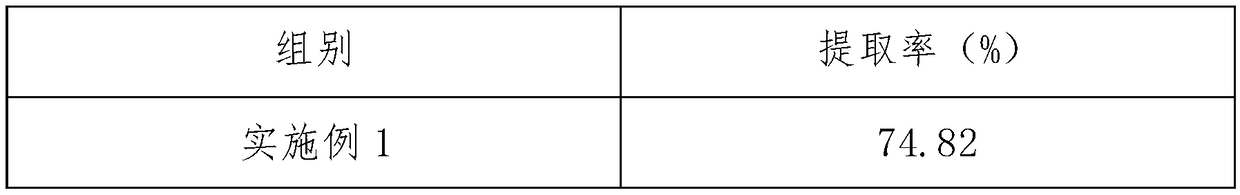

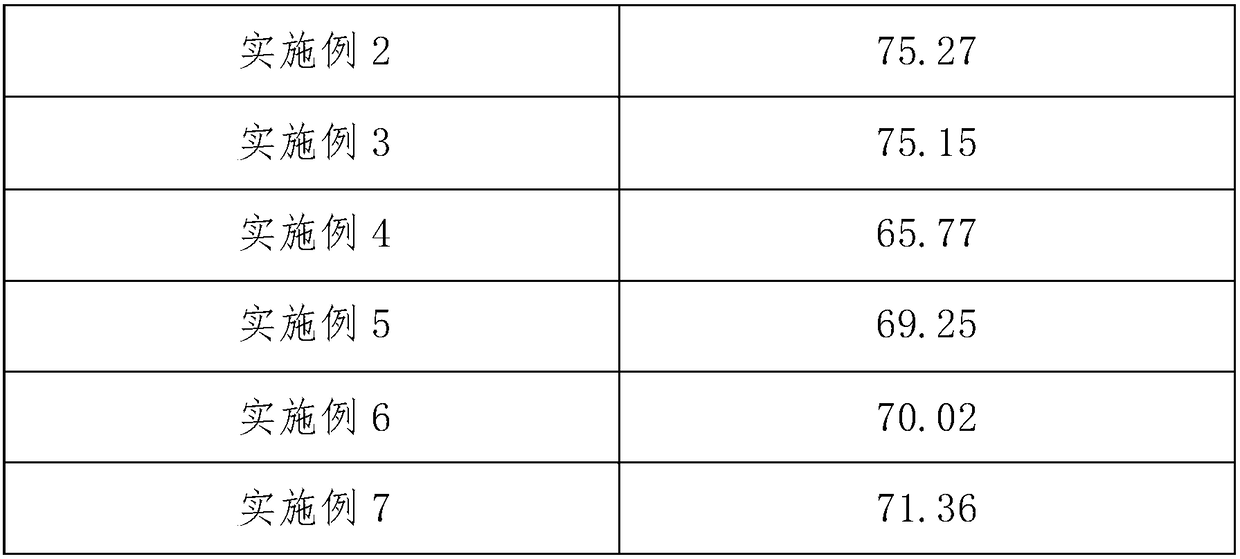

Examples

Embodiment 1

[0026] A white tea extract with high tea polyphenol content is characterized in that the preparation method of the white tea extract comprises the following steps:

[0027] (1) After the white tea leaves are dried, they are crushed into 20 mesh powders;

[0028] (2) Weigh 8g of white tea leaf powder and place it in a 500ml conical flask, add 350mL of distilled water and extract it in a hot water bath at 85°C, leaching at a constant temperature and shaking for 20 minutes, repeat the leaching 3 times, and decompress while hot after the leaching is completed Filtrate, put the filtrate into a clean container to obtain white tea powder water extract, and wash the residue with hot distilled water;

[0029] (3) Put the white tea leaf powder water extraction residue obtained in step (2) into a 500ml conical flask, add 350mL of 30% ethanol solution at 55°C, leaching with constant temperature and vibration for 35min, and depressurize immediately after the leaching is completed Filter, ...

Embodiment 2

[0037] A white tea extract with high tea polyphenol content is characterized in that the preparation method of the white tea extract comprises the following steps:

[0038] (1) Drying the white tea leaves and pulverizing them into 10 mesh powders;

[0039] (2) Weigh 6g of white tea leaf powder and place it in a 500ml conical flask, add 250mL of distilled water and extract it in a hot water bath at 75°C, leaching at a constant temperature and shaking for 15 minutes, repeating the leaching twice, and decompressing while hot after the leaching is completed Filtrate, put the filtrate into a clean container to obtain white tea powder water extract, and wash the residue with hot distilled water;

[0040] (3) Put the white tea powder water extraction residue obtained in step (2) into a 500ml conical flask, add 250mL of 20% ethanol solution at 45°C, leaching with constant temperature and vibration for 30min, and depressurize immediately after the leaching is completed Filter, and the...

Embodiment 3

[0048] A white tea extract with high tea polyphenol content is characterized in that the preparation method of the white tea extract comprises the following steps:

[0049] (1) Drying the white tea leaves and pulverizing them into 30 mesh powders;

[0050] (2) Weigh 10g of white tea powder and place it in a 500ml conical flask, add 400mL of distilled water and extract it in a hot water bath at 95°C, leaching at a constant temperature for 30 minutes, repeating the leaching 3 times, and decompressing while hot after the leaching is completed Filtrate, put the filtrate into a clean container to obtain white tea powder water extract, and wash the residue with hot distilled water;

[0051] (3) Place the white tea powder water extraction residue obtained in step (2) in a 500ml conical flask, add 400mL of 40% ethanol solution at 65°C, leaching for 40min with constant temperature and vibration, and depressurize immediately after the leaching is completed Filter, and the filtrate is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com