Air temperature testing box

An air temperature and test chamber technology, applied in laboratory utensils, air pressure chambers/airlocks, housings or chambers, etc., which can solve the problems of low calibration efficiency, poor air thermal conductivity, temperature fluctuation, uniformity and other indicators that cannot achieve relatively high performance. High precision and other issues to achieve rapid cooling effect, wide range of applicability, uniform temperature of the medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

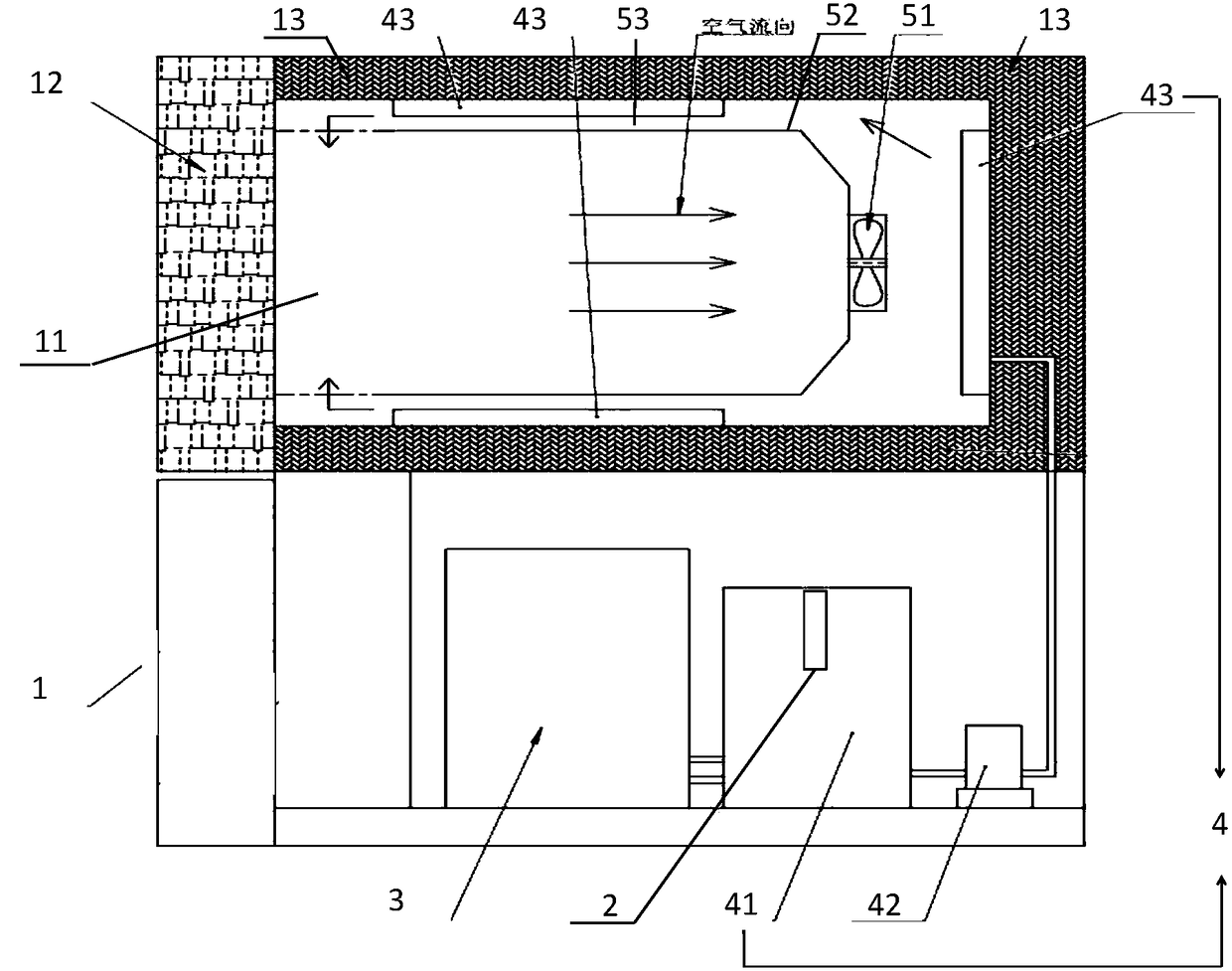

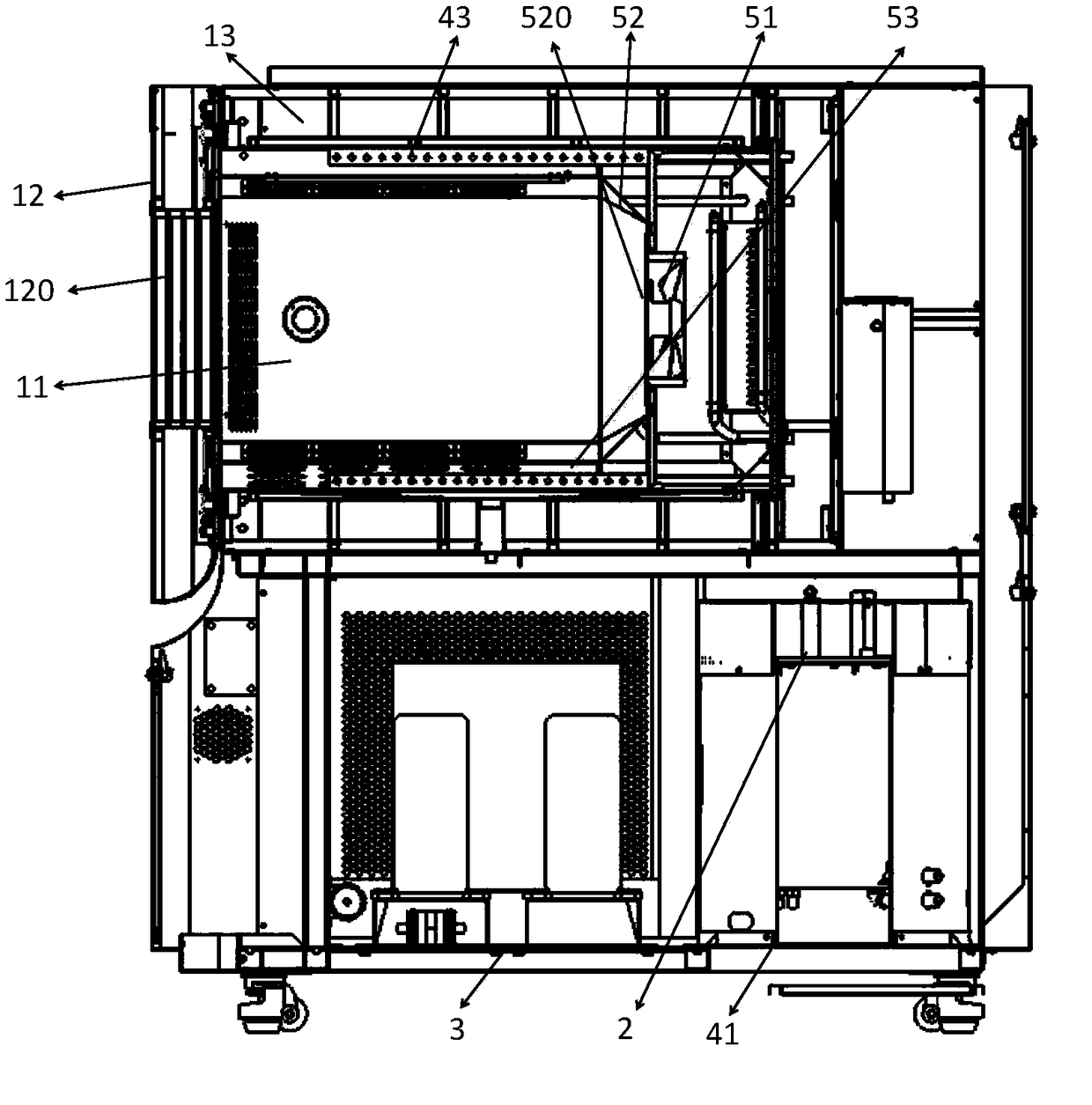

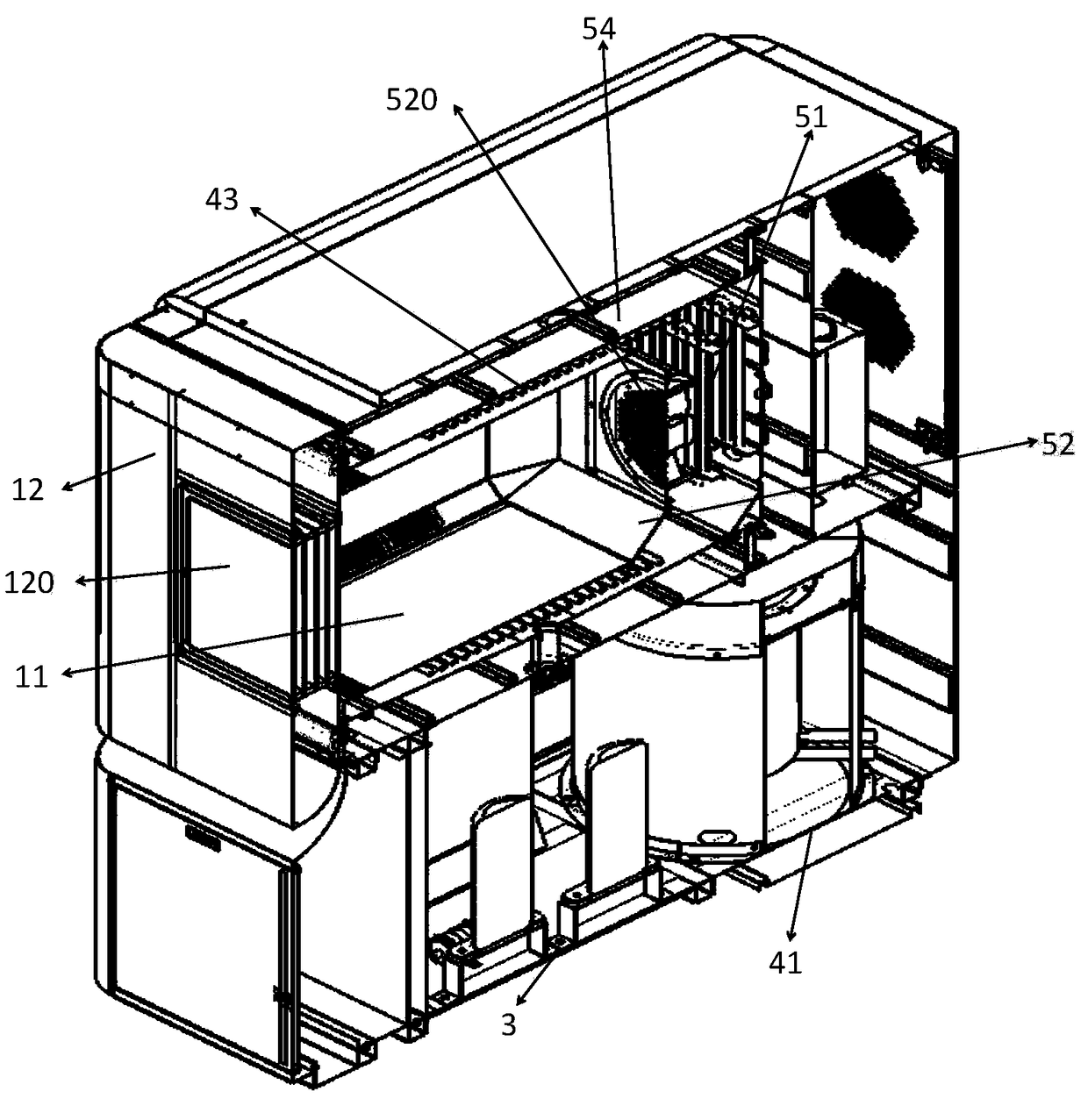

[0034]The present invention provides an air temperature test box, comprising: a control system, a box body 1, a heater 2 arranged in the inner cavity of the box body 1, a refrigeration device 3, a medium circulation device 4 and an air circulation device 5, the medium circulation device 4 are respectively connected with the heater 2 and the refrigerating device 3, and the medium circulation device 4 includes a closed circulation tank 5, a circulation pump 42, and a heat exchanger 43 connected in sequence to form a closed circuit, and the closed circulation tank 5 and The refrigeration device 3 is connected, the heater 2 is set in the closed circulation tank 5 for direct heating of the medium, the air circulation device 5 includes a frequency conversion fan 51 and an air duct plate 52, and the box body 1 is provided with a working area 11 and the working area door 12, the heat exchanger 43, the frequency conversion fan 51 and the air channel plate 52 are arranged in the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com