Removable protection barrel, and protection barrel and method for cast-in-place pile construction in water

A technology of cast-in-situ piles and casings, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of increased construction cost, laborious demolition work, low safety, etc., and achieves accelerated construction speed, low demolition cost, and easy to use The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] Production:

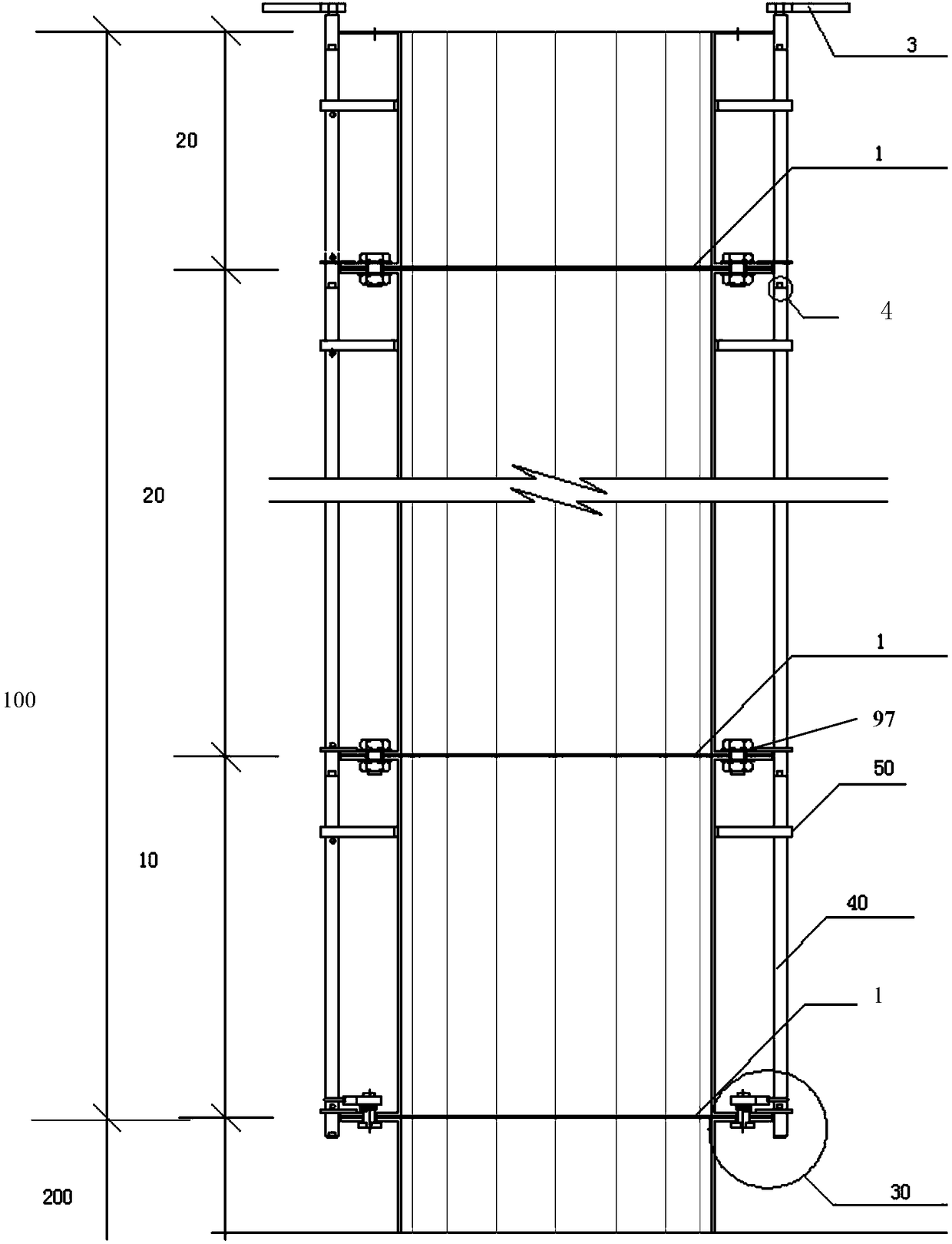

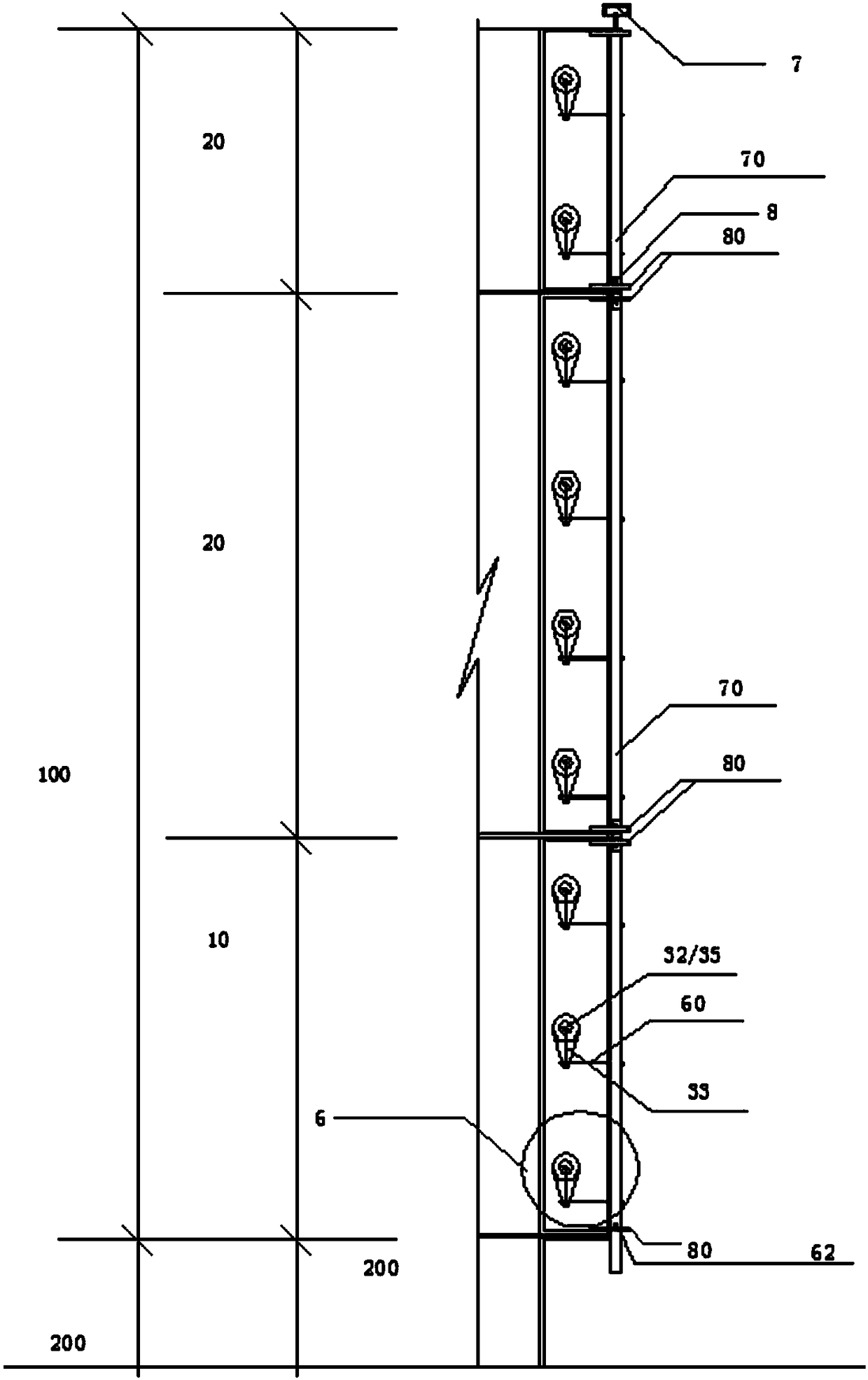

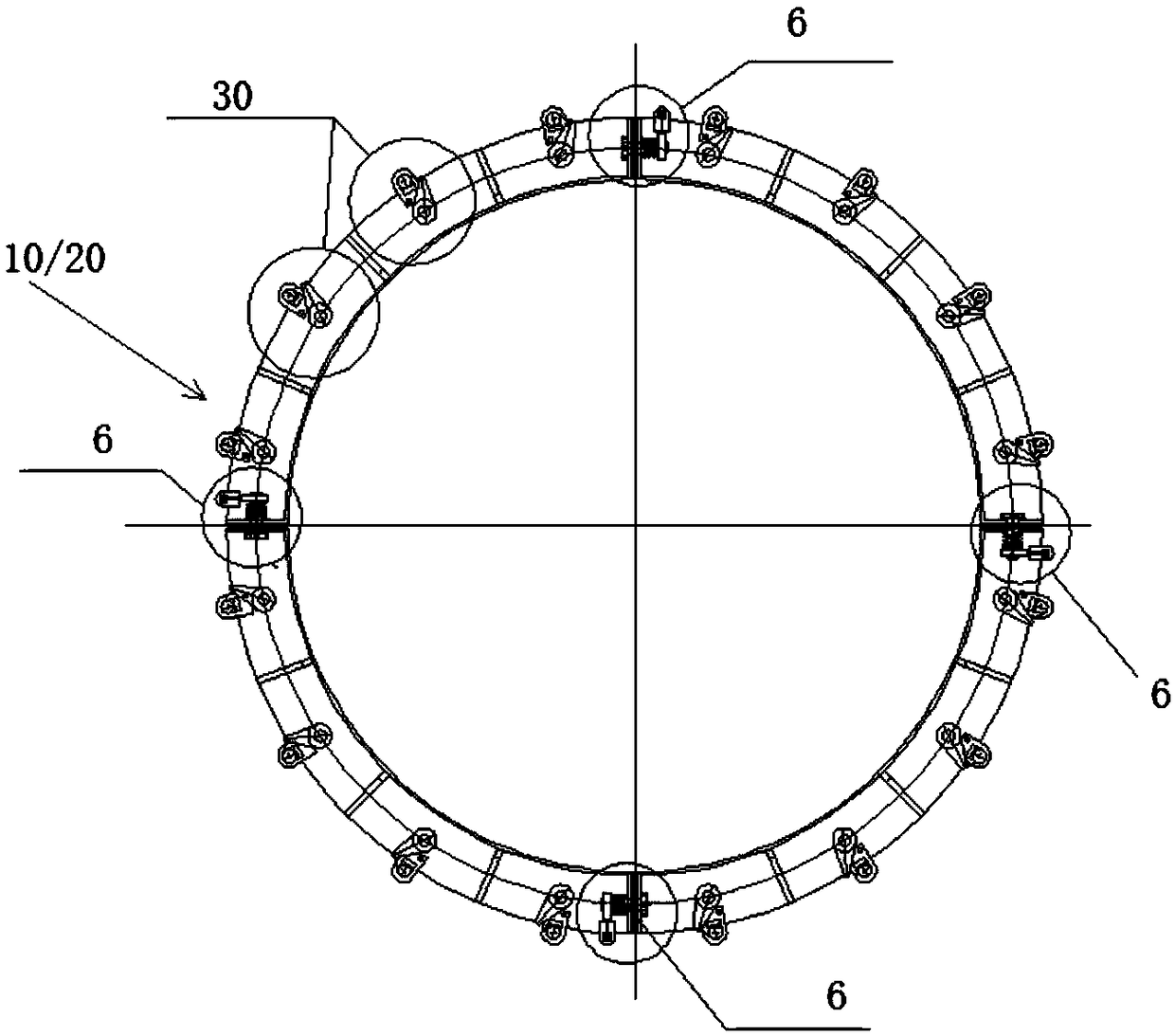

[0103] Several concrete cast-in-place piles are to be constructed in a water area. Due to the change of water depth, the length of the removable protective tube is 5-28 meters. The inner diameter of the removable section of the protective tube is 1.0 m, divided into four equal parts along the circumference. Ordinary protective cylinders are made 5 meters, 2 meters, and 1 meter long to suit the change of removable length caused by changes in water depth.

[0104] The ordinary protective cylinder and the bottom section protective cylinder are all made of steel. The cylinder body, flange piece, cylinder piece connecting plate, and lifting lugs are all 8 mm thick and connected by welding.

[0105] The tie rod is a square steel tube: 40 mm × 40 mm × 4 mm; the rotating rod is a round steel tube: a diameter of 48 mm × 3.5 mm.

[0106] The locking spring has an inner hole diameter of 60 mm, a working load of 8.0 kN, and a working range of 10 mm.

[0107] The diameter of t...

Embodiment 2

[0116] Production:

[0117] Several concrete cast-in-place piles need to be constructed in a sea area. Due to the change of water depth, the length of the removable protective tube is 12 to 32 meters. The inner diameter of the removable section of the protective cylinder is 1.8 meters, divided into four pieces along the circumference. The piece-type protective tube is made 5 meters, 2 meters long, and 1 meter to suit the change of the removable length caused by the change of water depth.

[0118] Ordinary protective cylinder and bottom section protective cylinder are made of steel. The cylinder body, flange piece, cylinder piece connecting plate, and lifting lugs are all 10 mm thick steel plates and welded.

[0119] The tie rod is a square steel tube: 40 mm × 40 mm × 4 mm; the rotating rod is a round steel tube: a diameter of 48 mm × 3.5 mm.

[0120] Locking spring, inner hole diameter 60 mm, working load 15 kN, working range 10 mm.

[0121] The diameter of the lock shaft is 45 mm.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com