Combined automatic liquid inlet chromatographic device

A technology of automatic liquid feeding and chromatography device, applied in the field of column chromatography, can solve problems such as poor chromatography effect and damage to the surface of silica gel, and achieve the effects of convenient and stable connection, reduction of volatilization and improvement of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

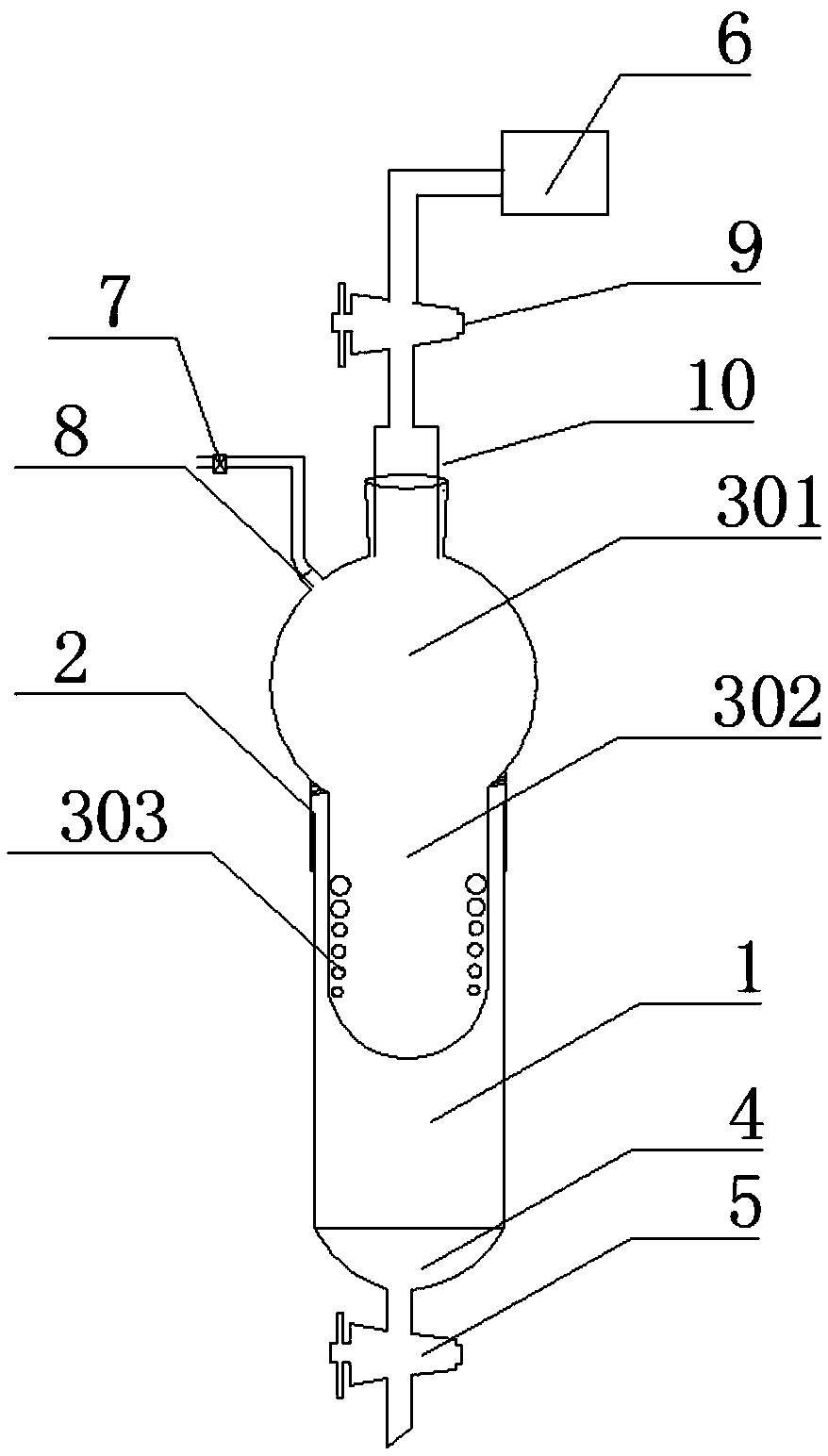

[0021] Such as figure 1 As shown, a combined automatic liquid-feeding chromatography device includes a chromatography column 1, a height-adjusting sleeve 2 threadedly connected with the chromatography column 1, a spherical sprue container movably connected with the height-adjusting sleeve 2, and a speed-regulating Type peristaltic pump 6 and booster pump 7, the spherical sprue container includes a spherical main body 301 and a cylindrical tube 302 whose lower end is closed and fixedly connected to the spherical main body 301, the top of the spherical main body 301 is connected to a rotary valve with a regulating valve 9 Joint 10, the speed-regulating peristaltic pump 6 is connected to the adapter 10 through a rubber hose; the top side of the spherical body 301 is provided with an air port 8 and the air port 8 is connected to the booster pump 7; The bottom wall of the spherical body 301 abuts against the upper end of the chromatography column 1, the upper end of the cylindrical...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap