Brushing electroplating process method, clad layer and application

A process method and electric brush plating technology, applied in electric brush plating process method and coating and application fields, can solve the problems of unstable product batch quality, difficult to control coating thickness, high purchase cost, and difficult to improve coating thickness. Control, hardness controllable, simple process operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

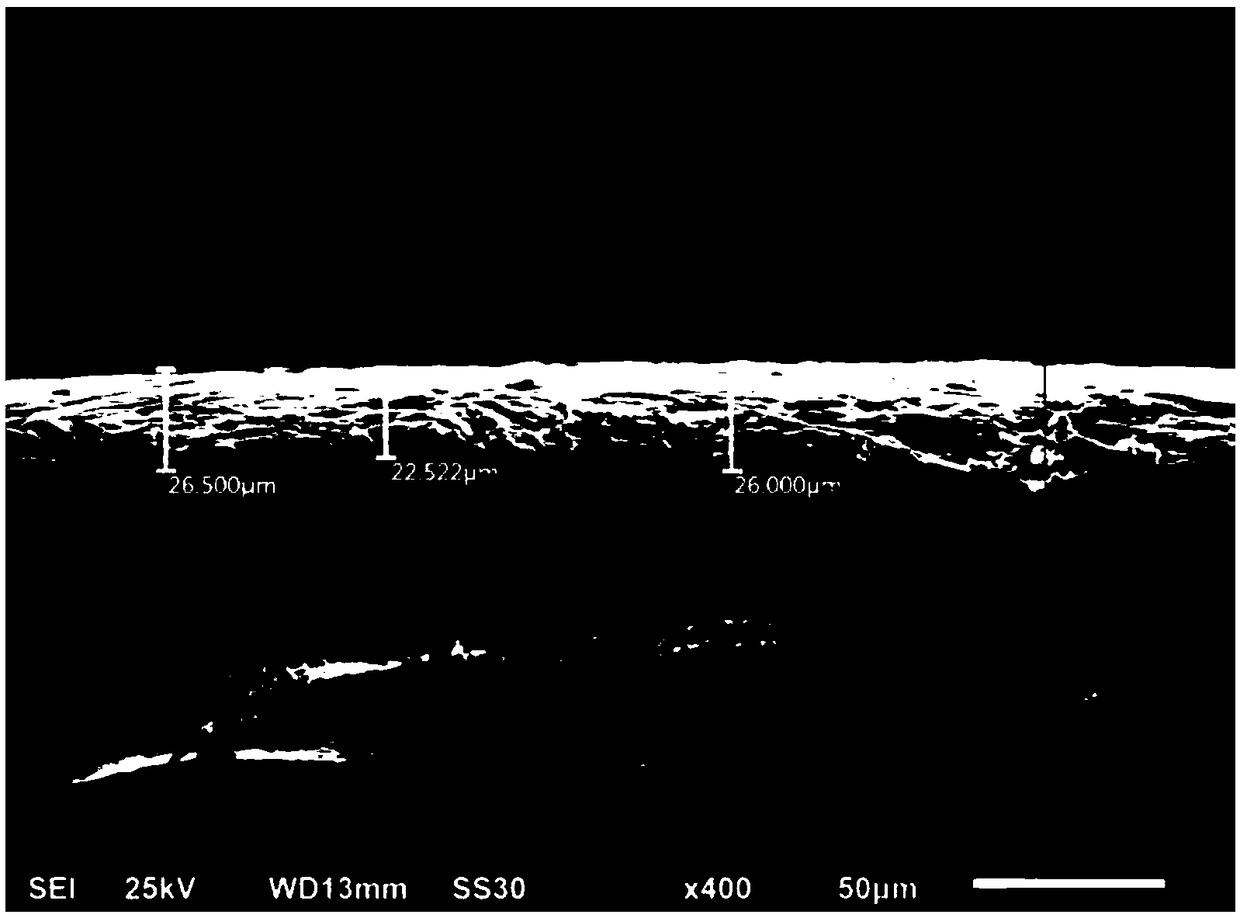

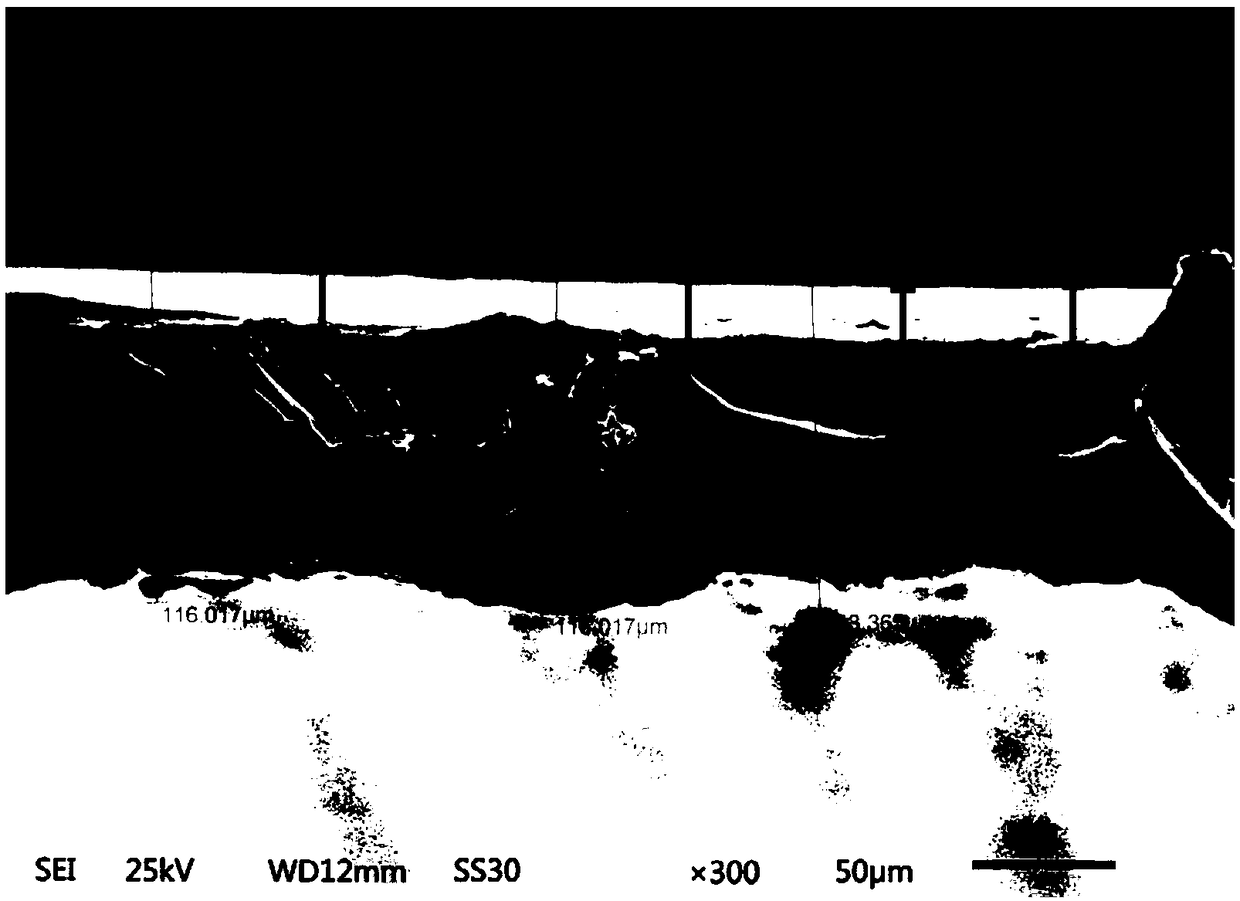

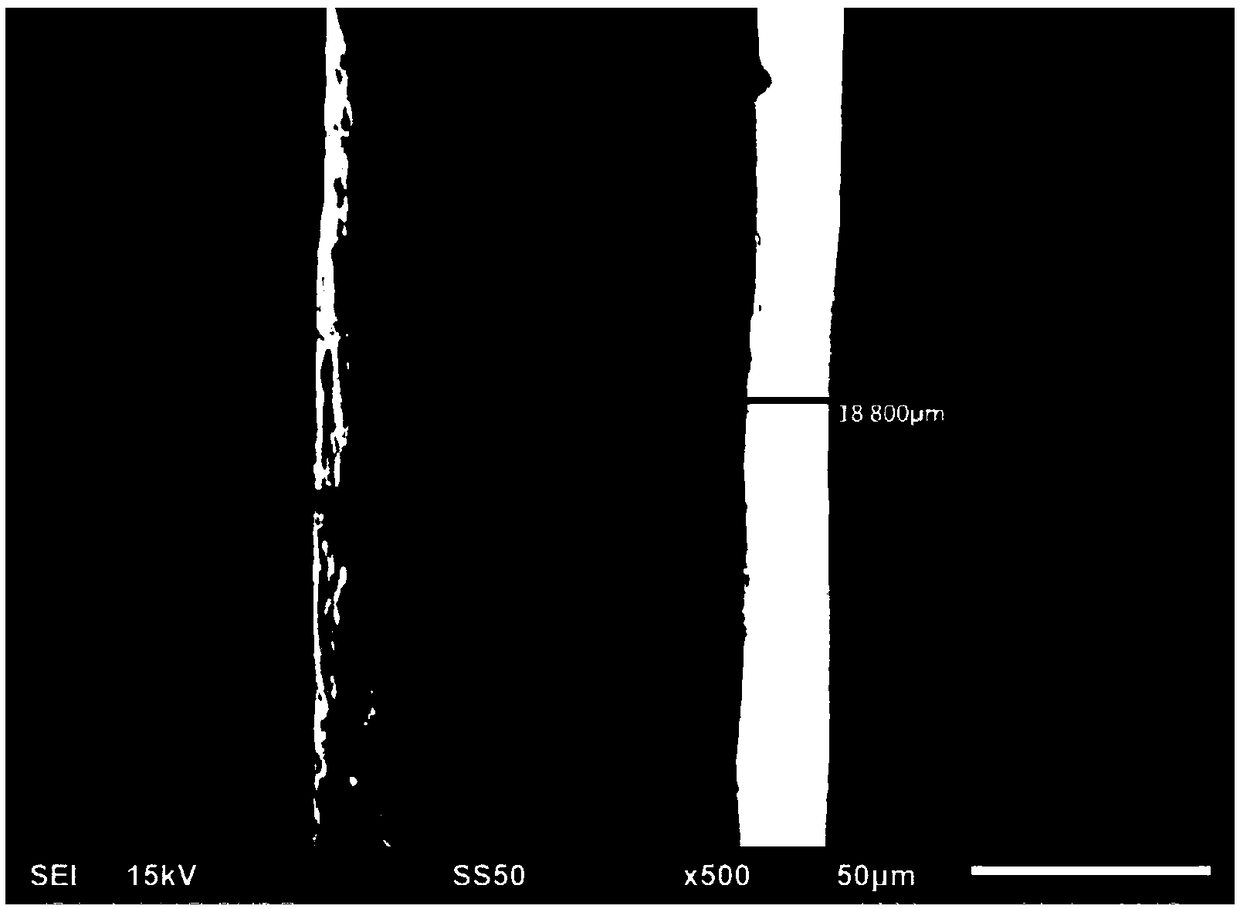

Image

Examples

Embodiment approach

[0093] As a preferred embodiment of the present invention, in step (d), the post-plating treatment includes cleaning, drying, polishing and oiling the plated parts;

[0094] As a preferred embodiment of the present invention, the brush plating process method includes the following steps:

[0095] (a) rough grinding the surface of the plated piece, then fine grinding, and then mechanically polishing the surface of the plated piece;

[0096] (b) Use electrocleaning liquid to carry out electrocleaning treatment on the polished plated parts. During the electrocleaning process, the plated part is used as the cathode, and the brush plating pen is used as the anode, and the working voltage is 8-12V;

[0097] Use activation solution to activate the plated parts after electro-cleaning treatment. During the activation process, the plated parts are used as anode, and the brush plating pen is used as cathode. The output voltage is 15-25V, and the activation time is 5-15s;

[0098] (c) Us...

Embodiment 1

[0106] The present embodiment provides a brush plating process, comprising the following steps:

[0107] (a) Copper is used as the base material of the plated part, and the surface of the plated part is roughly ground with a hand-held grinder loaded with 600 mesh sandpaper, and then slightly unidirectionally finely ground the surface of the plated part with a grinder loaded with 1000 mesh sandpaper. Remove the impurities on the surface of the plated parts, and at the same time mechanically polish the surface of the plated parts to obtain a bright, fresh and microscopically rough surface of the plated parts;

[0108] (b) Electrocleaning is carried out to the polished plated parts with electrolytic solution;

[0109] During the electro-cleaning treatment, the plated parts are used as the cathode, and the brush plating pen is used as the anode. The working voltage is 8V. Sodium chloride 2g / L;

[0110] Use the activation solution to activate the electro-cleaning treatment of the...

Embodiment 2

[0116] This embodiment provides a brush plating process, except that the composition of the electrolytic solution in step (b) is different, other steps and process parameters are the same as those in embodiment 1.

[0117] The electric cleaning liquid is mainly made of the following raw materials: sodium hydroxide 9g / L, sodium carbonate 50g / L, trisodium phosphate 50g / L and sodium silicate 9g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com