Assembled large tent

A prefabricated, large-scale technology, applied in tents/canopies, building types, buildings, etc., can solve problems such as complex bracket structure, inconvenient use, deformation of internal accounts and canopy, etc., to reduce the weight of tents, avoid fires, and improve portability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

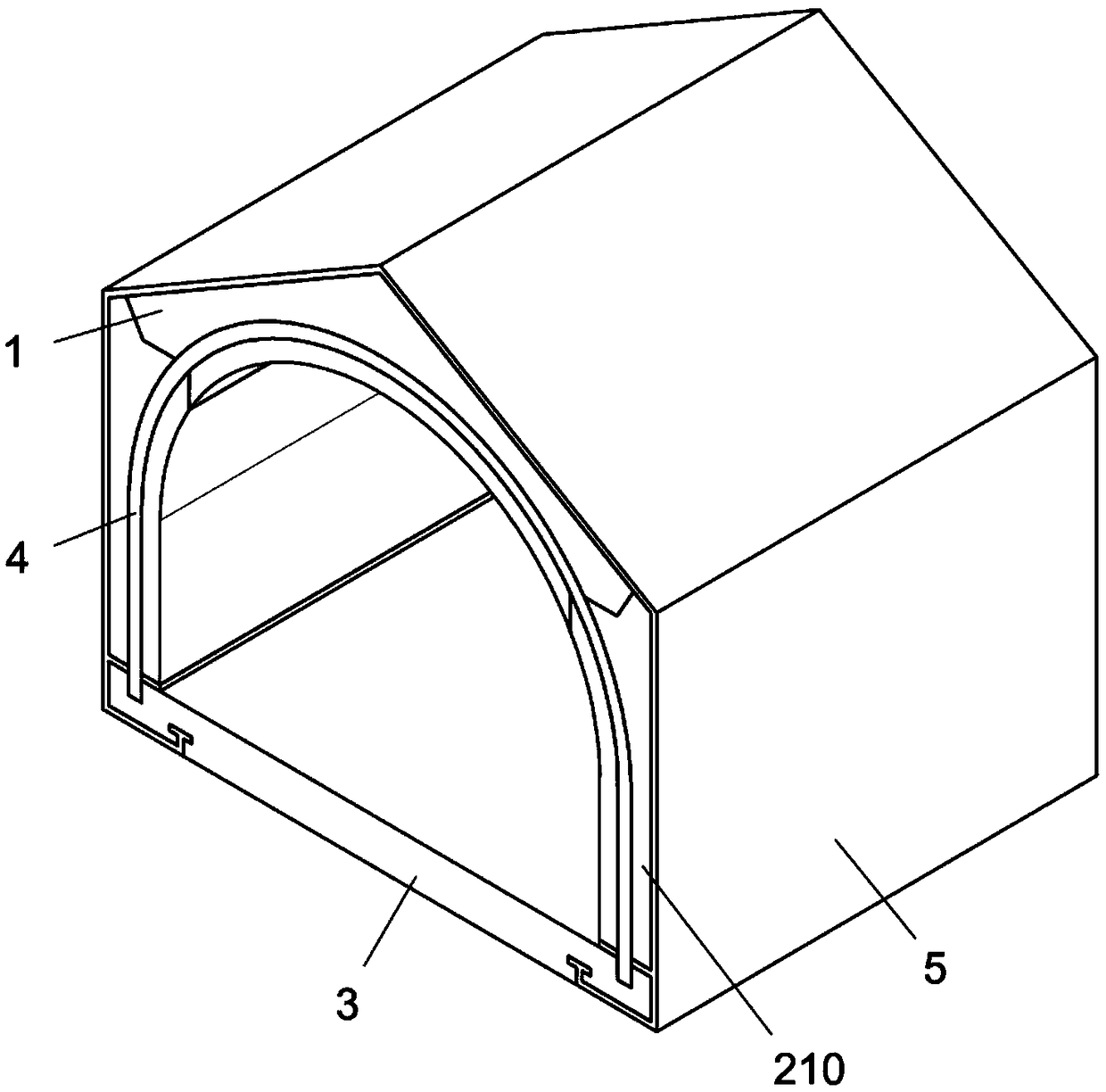

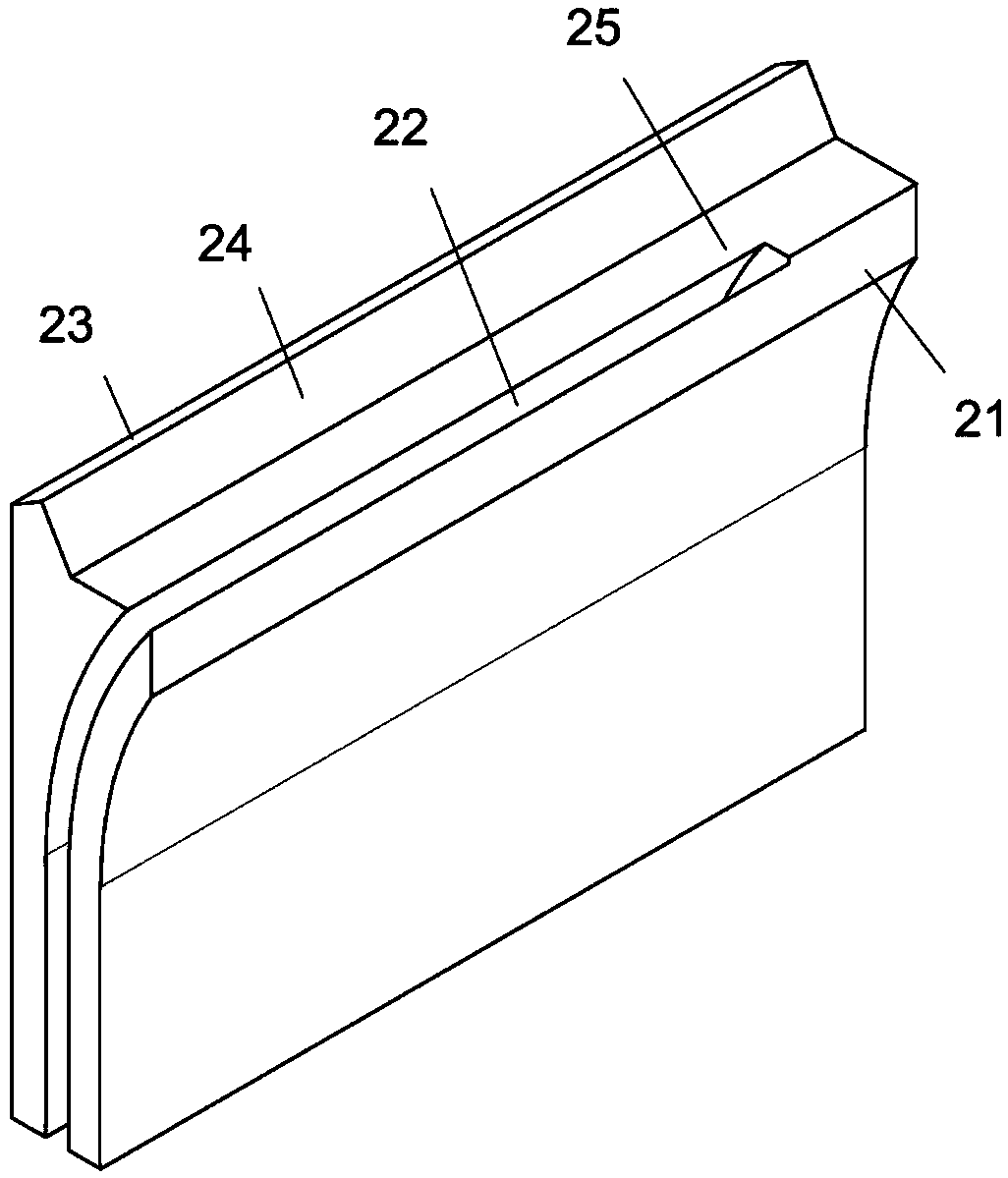

[0021] Such as Figure 1-6 As shown, an assembled large-scale tent includes a base 3, an internal support 4 is installed on the upper part of the base 3, the internal support is an inverted U-shaped structure, and two side walls of the internal support 4 are respectively inserted with a side The wall assembly 210, the upper end of the inner support 4 is plugged with the sky curtain assembly 1, and the sky curtain assembly 1 and the two side wall assemblies 210 are closely combined; the sky curtain assembly 1 and the two side wall assemblies 210 constitute the main body of the arched tent, and the main body of the arched tent An outer decorative layer 5 is installed on the outer side of the wall.

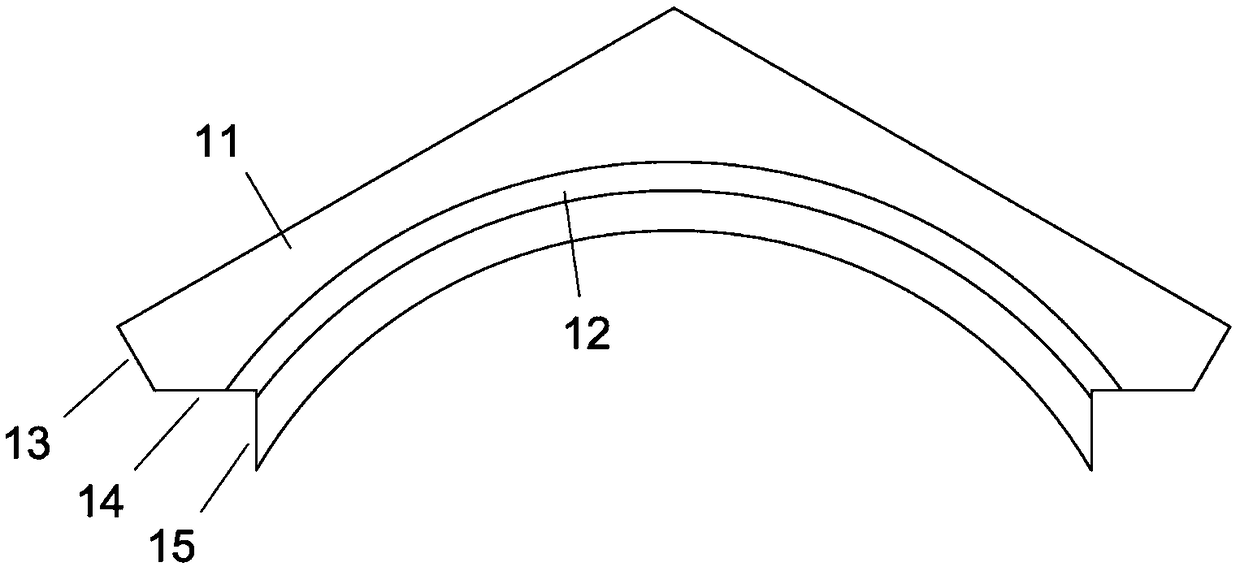

[0022] The sky curtain assembly 1 inc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap