Falling-film type absorbing and condensing device and method

A condensing device and falling film technology, applied in the field of falling film absorption condensing devices, can solve the problems of unstable operation, unsatisfactory mass transfer and heat transfer effect, etc., achieve strong operability, save equipment fixed investment, prevent The effect of flooding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

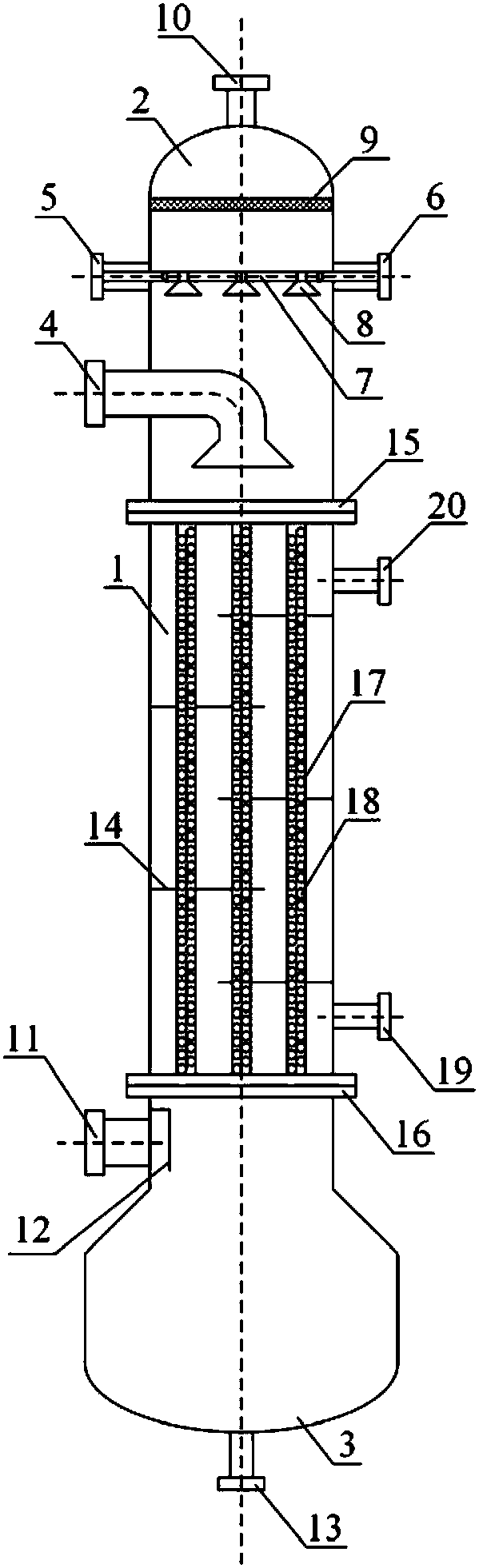

[0024] Such as figure 1 As shown, a falling film absorption and condensation device for treating ammonia-containing waste gas includes a cylinder, an upper tube box, a bottom liquid collection tank, an ammonia-containing waste gas inlet, a sulfuric acid solution inlet, an absorption liquid loop, a nozzle, and a wire mesh defoamer device, top gas outlet, bottom gas outlet, arched baffle, absorption liquid outlet, distance baffle, tube sheet, heat exchange tube, packing, circulating cooling water inlet and circulating cooling water outlet. The ammonia-containing waste gas inlet and the sulfuric acid solution inlet are located in the upper pipe box, and the gas inlet is below the absorption liquid inlet. There is a top gas outlet on the head of the upper pipe box, and the absorption liquid flows into the bottom liquid collection tank through the tube side. A bottom gas outlet is set above the surface, and an absorption liquid outlet is set at the bottom of the kettle. Two absorp...

Embodiment 2

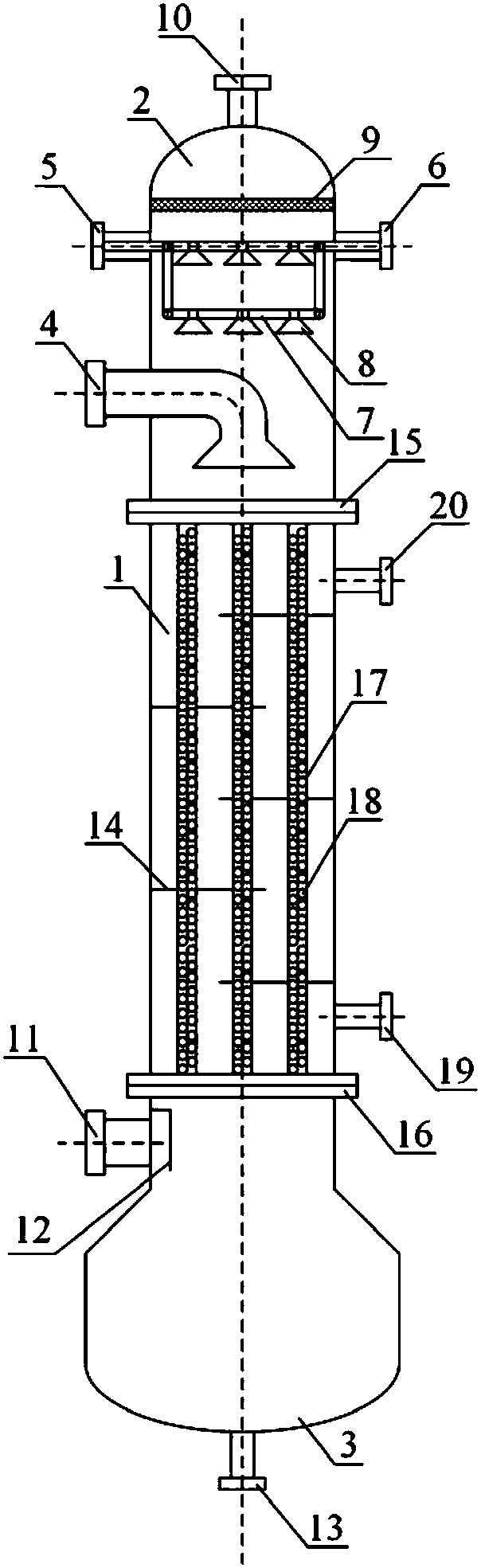

[0028] Such as figure 2 As shown, a falling film absorption and condensation device for methacrylic acid reaction gas, including a cylinder, an upper tube box, a bottom liquid collection tank, a reaction gas inlet, a methacrylic acid aqueous solution inlet, an absorption liquid loop, a nozzle, and a screen Demister, top gas outlet, bottom gas outlet, arched baffle, absorption liquid outlet, distance baffle, tube sheet, heat exchange tube, packing, circulating chilled water inlet and circulating chilled water outlet. The reaction gas inlet and the methacrylic acid aqueous solution inlet are located in the upper tube box, and the gas inlet is below the solution inlet. There is a top gas outlet on the head of the upper tube box, and the absorption liquid flows into the bottom liquid collection tank through the tube side. A bottom gas outlet is set above the surface, and an absorption liquid outlet is set at the bottom of the kettle. Two absorption liquid inlets are arranged, sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com