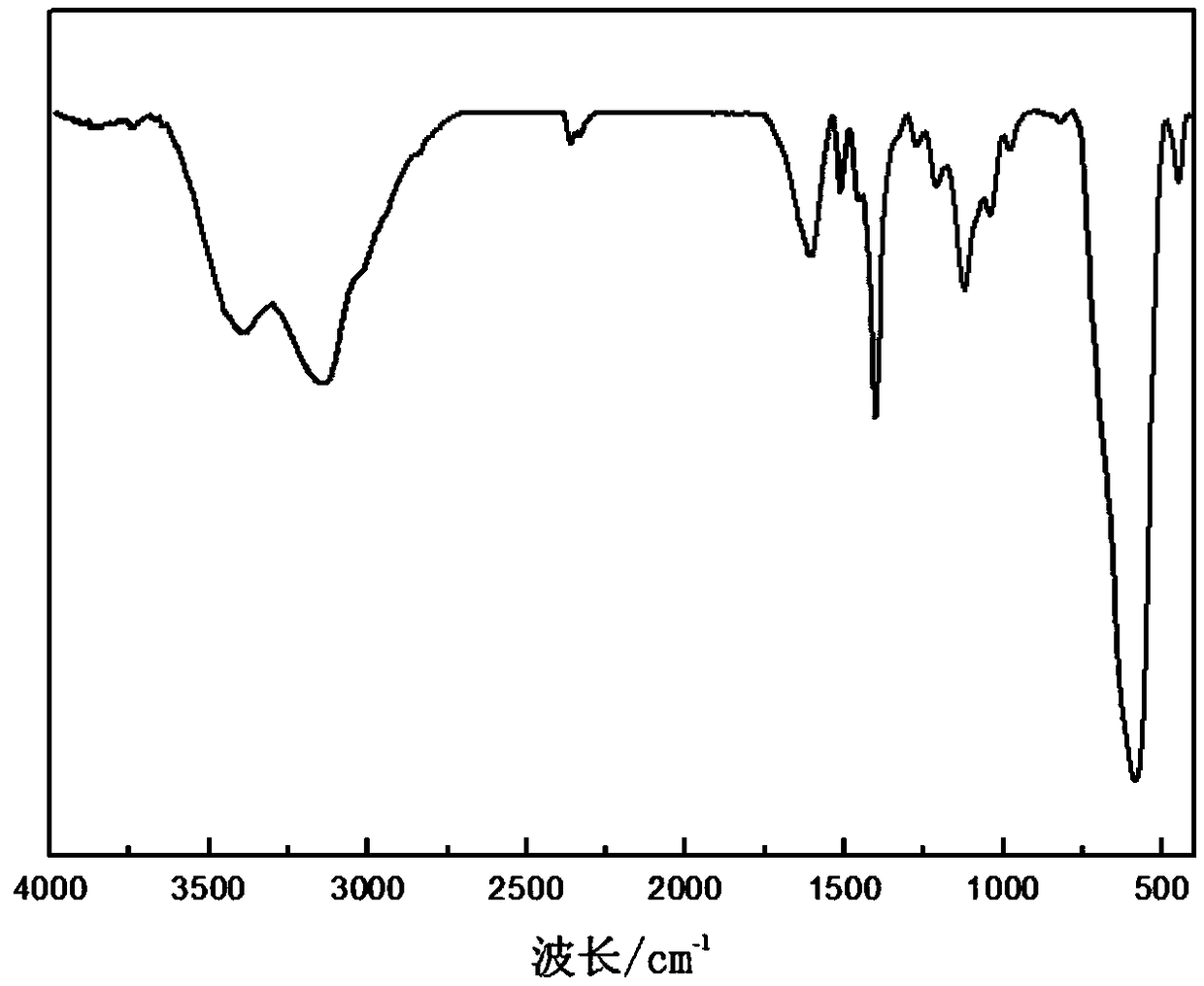

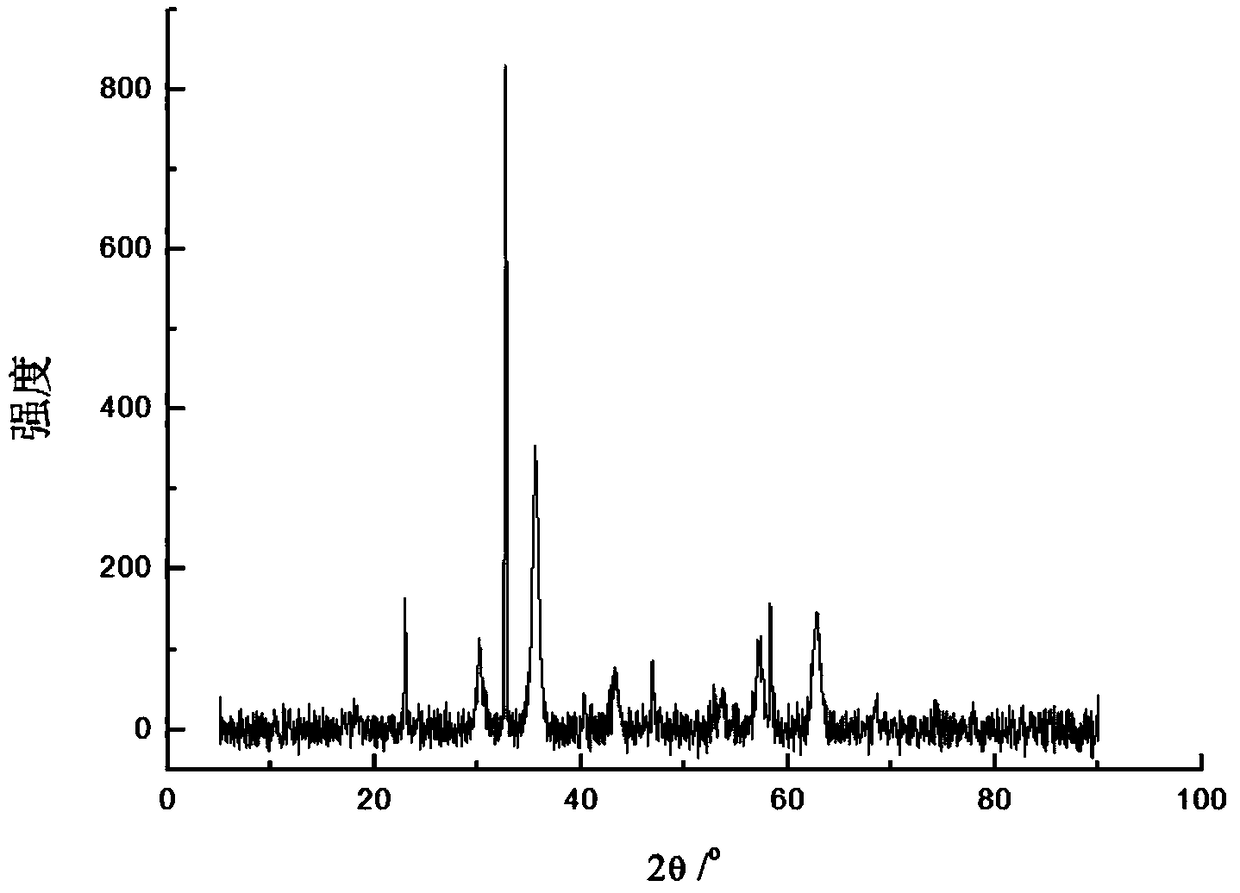

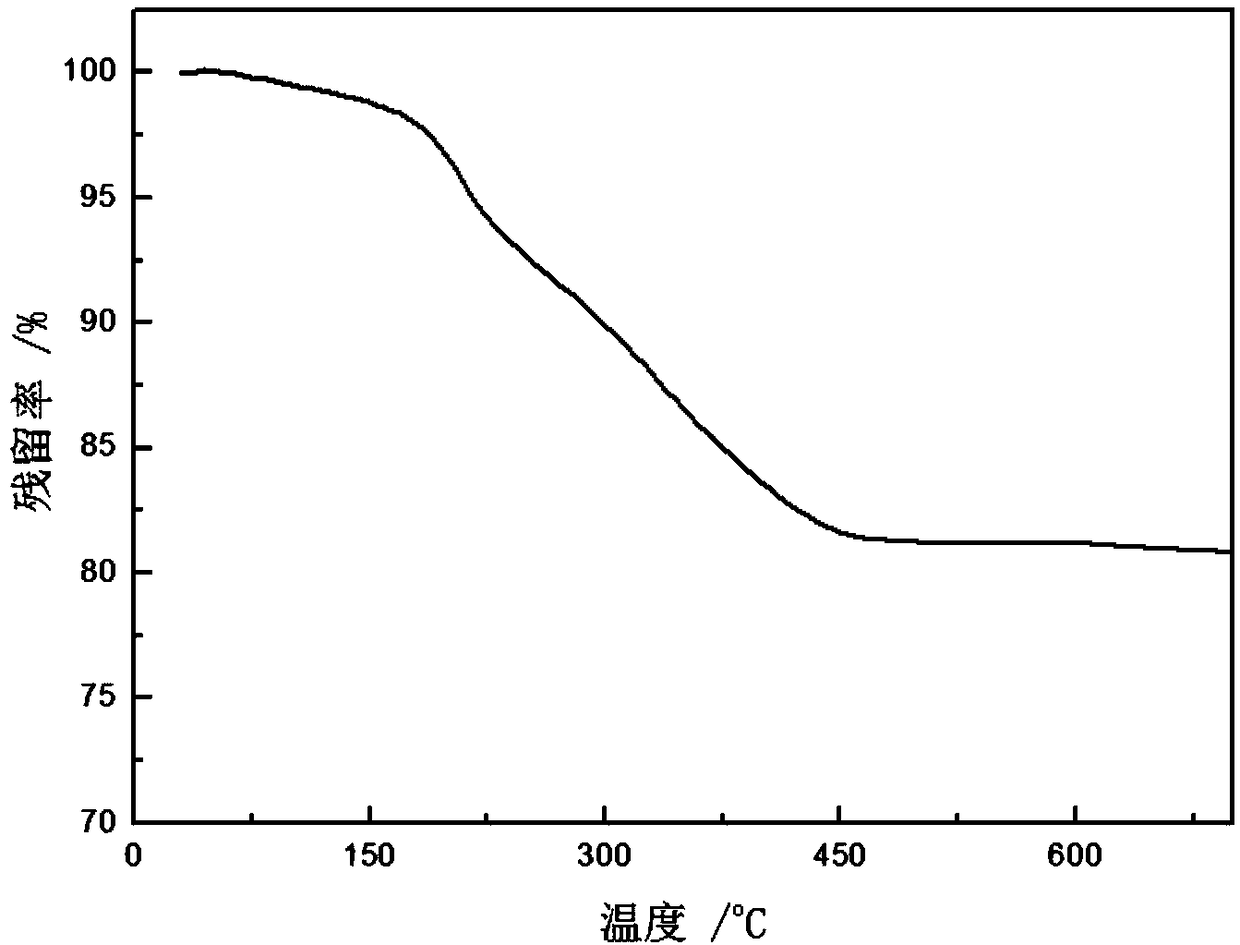

Magnetic nanometer particle based on lignin carboxylate as well as preparation method and application thereof to chromium adsorption

A technology of magnetic nanoparticles and lignin, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc. problem, to achieve the effect of low price, lower production cost, and improved adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Dissolve 2.5g of ferrous sulfate and 3g of ferric chloride in 100mL of water, transfer to a four-necked flask, heat up to 80°C under mechanical stirring, slowly drop into 10g of 25% ammonia solution at a rate of 1 drop / second. After the dropwise addition is completed, heat-preserve and ripen for 3.5 hours. After dissolving 3g of sodium lignin carboxylate into 12g of aqueous solution, drop it into the above reaction system together with 18g of absolute ethanol at the same time, the dropping rate is 1 drop / second, and keep stirring for 2 hours after the dropping is completed. Finally, the magnetic particles were separated by a permanent magnet, washed three times with ethanol, and vacuum-dried at 60°C to obtain lignin carboxylate magnetic nanoparticles. The average particle size of the prepared lignin carboxylate magnetic nanoparticles is about 71nm, and the BET specific surface area is 412m 2 / g.

[0045]1 g of lignin carboxylate magnetic nanoparticles was added to 100...

Embodiment 2

[0047] Dissolve 5g of ferrous sulfate and 6g of ferric chloride in 100mL of water, transfer to a four-necked flask, heat up to 90°C under mechanical stirring, and slowly add 20g of 25% ammonia solution dropwise at a rate of 1 drop / second. After the dropwise addition, heat preservation and aging for 4h. After dissolving 6g of calcium lignin carboxylate into 24g of aqueous solution, drop it into the above-mentioned reaction system together with 36g of methanol at the same time, the dropping speed is 1 drop / second, and keep stirring for 1 hour after the dropping is completed. Finally, the magnetic particles were separated by a permanent magnet, washed three times with ethanol, and dried in vacuum at 50°C to obtain lignin carboxylate magnetic nanoparticles. The average particle size of the prepared lignin carboxylate magnetic nanoparticles is about 99nm, and the BET specific surface area is 330m 2 / g.

[0048] 1 g of lignin carboxylate magnetic nanoparticles was added to 100 mL ...

Embodiment 3

[0050] Dissolve 3g of ferrous sulfate and 5g of ferric chloride in 100mL of water, transfer to a four-necked flask, heat up to 70°C under mechanical stirring, slowly drop into 15g of 25% ammonia solution at a rate of 1 drop / second. After the dropwise addition, heat preservation and aging for 3h. After dissolving 5g of magnesium lignin carboxylate into 25g of aqueous solution, drop it into the above reaction system together with 37.5g of n-propanol at the same time, at a rate of 1 drop / second, and keep stirring for 3 hours after the addition. Finally, the magnetic particles were separated by a permanent magnet, washed three times with ethanol, and vacuum-dried at 70°C to obtain lignin carboxylate magnetic nanoparticles. The average particle size of the prepared lignin carboxylate magnetic nanoparticles is about 117nm, and the BET specific surface area is 296m 2 / g.

[0051] 1 g of lignin carboxylate magnetic nanoparticles was added to 100 mL of Cr(VI) solution with a concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap