Honing wheel grinding method applied to powerful honing teeth of numerical control inner gear honing wheel

A technology of gear teeth and internal teeth, which is applied in the field of honing and grinding of powerful honing gears for CNC internal gear honing wheels, which can solve the problems of increased processing costs and unfavorable promotion and use of honing gears, achieve stable honing quality, and improve processing economy The effect of improving performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

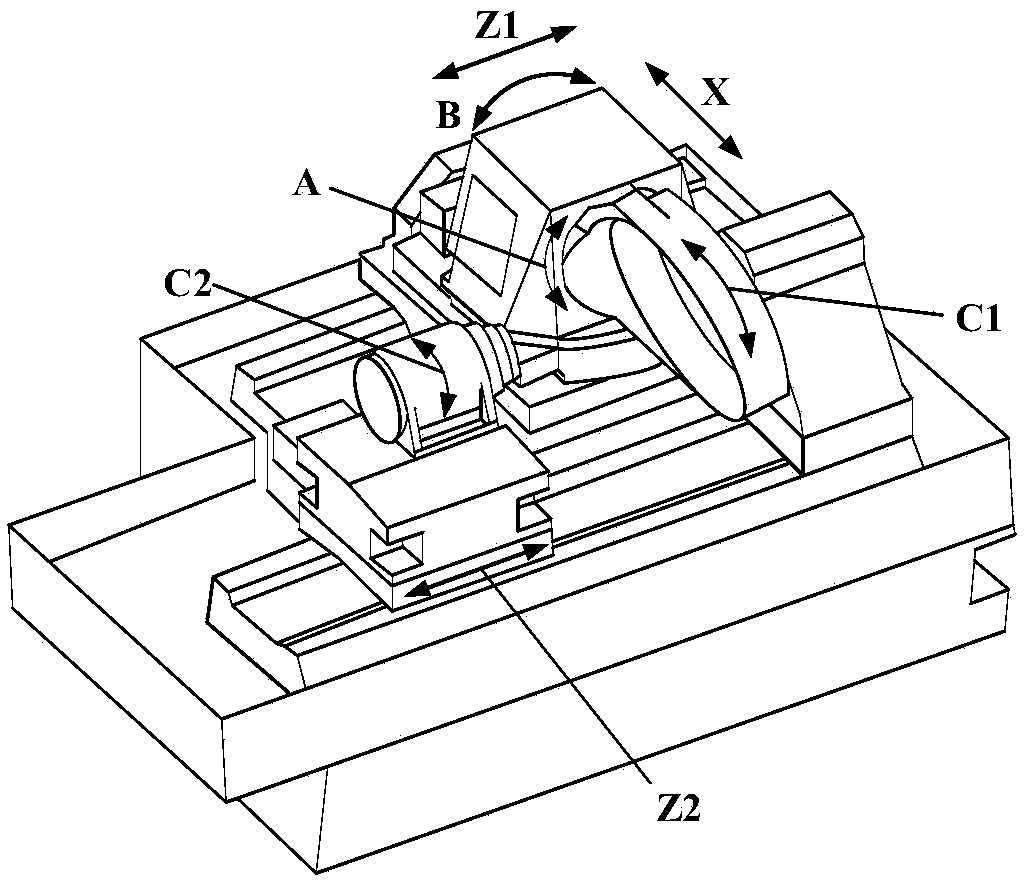

[0041]The processing machine tool is Fassler HMX-400 CNC internal gear honing wheel powerful gear honing machine, figure 1 It is a schematic diagram of the machine tool model and the corresponding motion axis. The tool uses a microcrystalline corundum internal tooth honing wheel, and the processing object is a 20CrMnTi disc-shaped external helical gear. The basic parameters of the processed gear are: modulus m n =2.25, number of teeth z 1 =73, gear helix angle β 1 =33°, pressure angle α n =17.5°,variation coefficient x 1 =0. The basic parameters of the internal gear honing wheel are: modulus m n =2.25, number of teeth z 2 =123, honing wheel helix angle β 2 =41.722°, pressure angle α n =17.5°,variation coefficient x 2 =0.

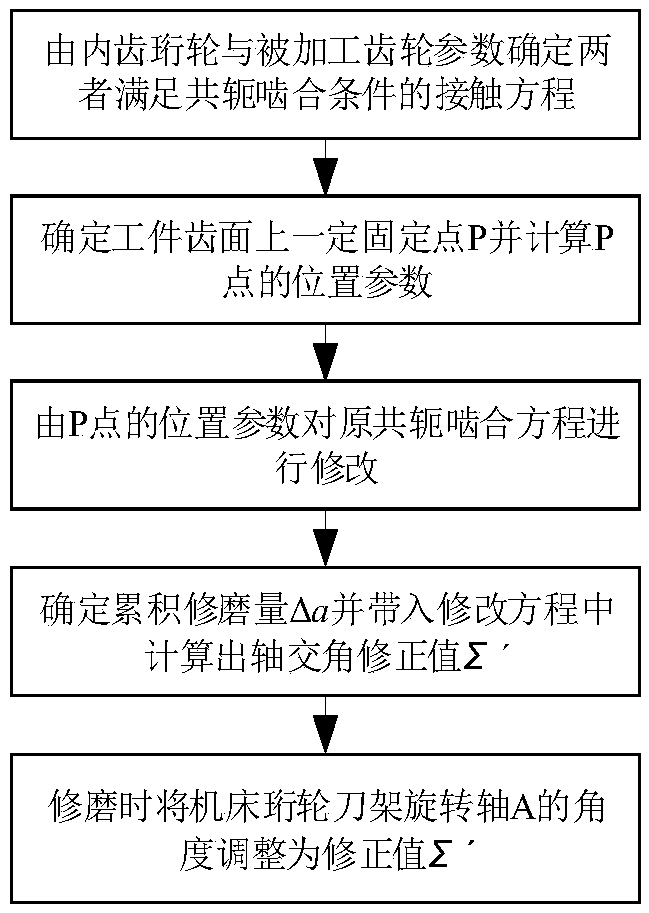

[0042] see figure 2 , a kind of honing wheel grinding operation steps applied to CNC internal gear honing wheel powerful honing is as follows:

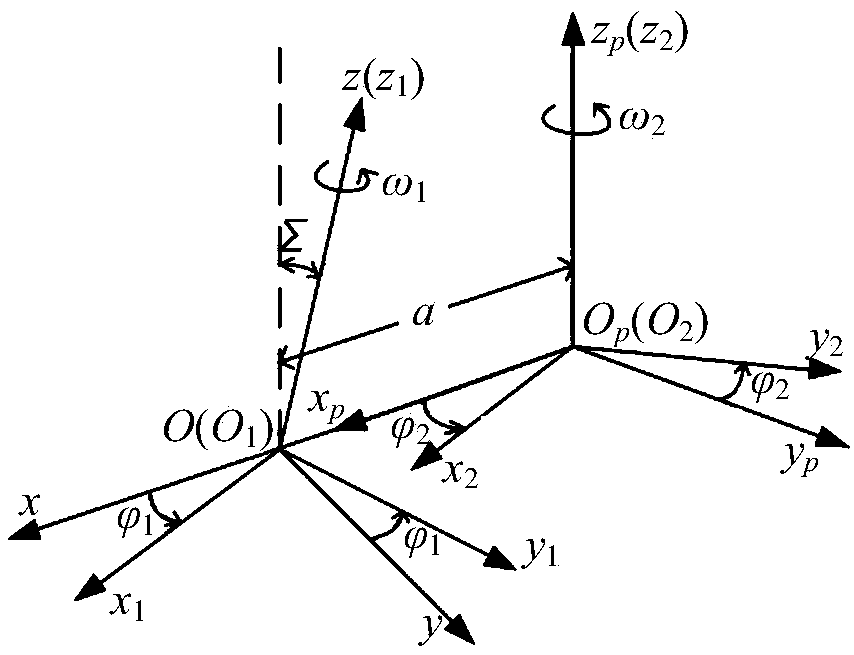

[0043] (1). Determine the conjugate meshing equation of the machined gear and the internal gear honi...

Embodiment 2

[0076] The processing machine tool is Fassler HMX-400 CNC internal gear honing wheel powerful honing machine. The tool uses microcrystalline corundum internal gear honing wheel, and the processing object is 20CrMnTi disc-shaped external helical gear. The basic parameters of the processed gear are: modulus m n =1.94, number of teeth z 1 =57, gear helix angle β 1 =23°, pressure angle α n =18°,variation coefficient x 1 =0. The basic parameters of the internal gear honing wheel are: modulus m n =1.94, number of teeth z 2 =151, honing wheel helix angle β 2 =31°, pressure angle α n =18°,variation coefficient x 2 =0. .

[0077] Step (1), the calculation results of other required parameters are shown in Table 3.

[0078] Table 3 Calculation results of other parameters

[0079]

[0080] The derivation of the conjugate meshing equation of the machined gear and the internal tooth honing wheel is the same as that in Embodiment 1.

[0081] In step (2), the definition of poi...

Embodiment 3

[0088] The processing machine tool is Fassler HMX-400 CNC internal gear honing wheel powerful honing machine, the tool uses microcrystalline corundum internal tooth honing wheel, and the processing object is 20CrMnTi disc-shaped external helical gear. The basic parameters of the processed gear are: modulus m n =2.36, number of teeth z 1 =18, gear helix angle β 1 =33°, pressure angle α n =17°,variation coefficient x 1 =0. The basic parameters of the internal gear honing wheel are: modulus m n =2.36, number of teeth z 2 =95, honing wheel helix angle β 2 =41°, pressure angle α n =17°,variation coefficient x 2 =0.

[0089] Step (1), the calculation results of other required parameters are shown in Table 5.

[0090] Table 5 Calculation results of other parameters

[0091]

[0092] The derivation of the conjugate meshing equation of the machined gear and the internal tooth honing wheel is the same as that in Embodiment 1.

[0093] In step (2), the definition of point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com