Multifunctional steel stacking crane

A palletizer and multi-functional technology, applied in the field of multi-functional steel palletizers, can solve problems such as high labor intensity, inability to automatically palletize palletizers, and easy occurrence of bruises, etc., and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

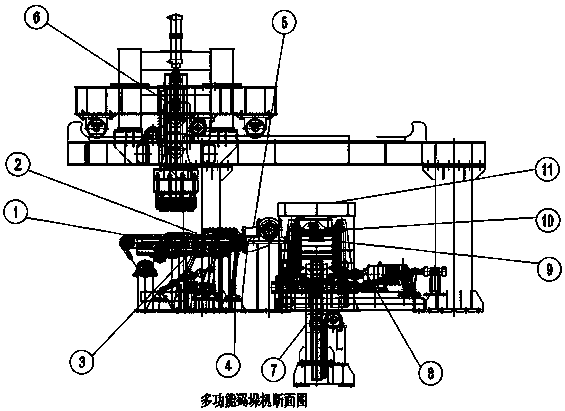

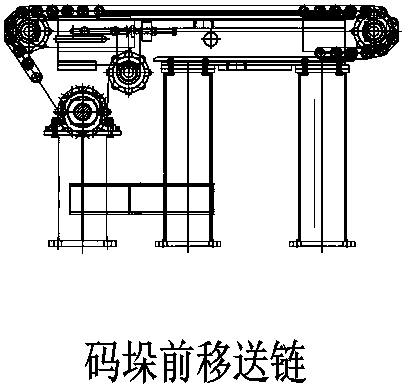

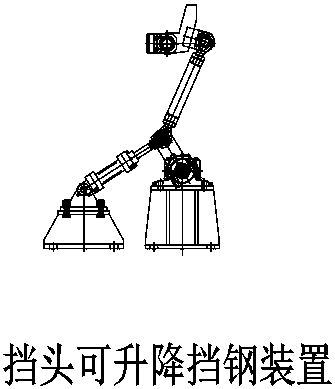

[0025] The first embodiment: the multi-functional palletizer in this embodiment is arranged sequentially from the flow direction of the section steel ① the front conveyor chain of the palletizer, ② the stopper head can be lifted and lowered to stop the steel device, ④ the stopper head can move back and forth to move the steel stopper device, ⑤ flipping electromagnetic Iron, ⑦ palletizing lifting platform, ⑧ adjustable transport roller table with vertical rollers on both sides, the conveyor chain in front of the palletizer mentioned above will convey the continuous H-shaped steel, and the block head can be raised and lowered and the steel blocking device will be continuously formed Rows of H-shaped steel are divided into groups, and each group of H-shaped steel is transported to the front of the rear stopper, which can move back and forth before the steel stopper device, and then flips the electromagnet to the palletizing lifting platform, and the lifting platform is lowered to a...

no. 2 example

[0026] The second embodiment: the multi-functional palletizer in this embodiment is arranged sequentially from the flow direction of the section steel ① the front conveyor chain of the palletizer, ② the stopper head can be lifted and lowered to stop the steel device, ④ the stopper head can move back and forth to move the steel stopper device, ⑤ flipping the electromagnetic Iron, ⑥ lifting and translation electromagnet, ⑦ stacking lifting platform, ⑧ adjustable transport roller table with vertical rollers on both sides, the conveyor chain in front of the stacker conveys the continuous channel steel or angle steel, and the stop The lifting and lowering steel device divides the continuous rows of section steel into groups, and each group of section steel is transported to the front of the rear stopper, which can move forward and backward. The set of profiled steel is flipped upside down by the flipping electromagnet on the first layer of profiled steel on the palletizing lifting p...

no. 3 example

[0027] The third embodiment: In this embodiment, the multi-functional palletizer is arranged sequentially from the flow direction of the section steel ① the front conveyor chain of the palletizer, ② the stopper can be lifted and lowered to stop the steel device, ③ the steel dividing and spacing device, ④ the stopper can move back and forth Steel blocking device, ⑤ flipping electromagnet, ⑥ lifting and translation electromagnet, ⑦ stacking and lifting platform, ⑧ vertical rollers on both sides adjustable transport roller table, ⑨ telescopic supporting steel device, ⑩ steel dividing and spacing device, The gantry frame with fixed distance and supporting steel device, the conveyor chain in front of the stacker conveys the continuous stacked elevator guide rail steel or T-shaped steel, and the movable stopper device will continuously form rows The profiled steel is divided into groups, and each group of profiled steel is transported to the front of the rear stopper, which can move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com