Dirt separation equipment for water environment

A technology for separation equipment and water environment, applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc. Large manual cleaning of labor intensity and other problems can save labor intensity, reduce the occurrence rate of failures, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

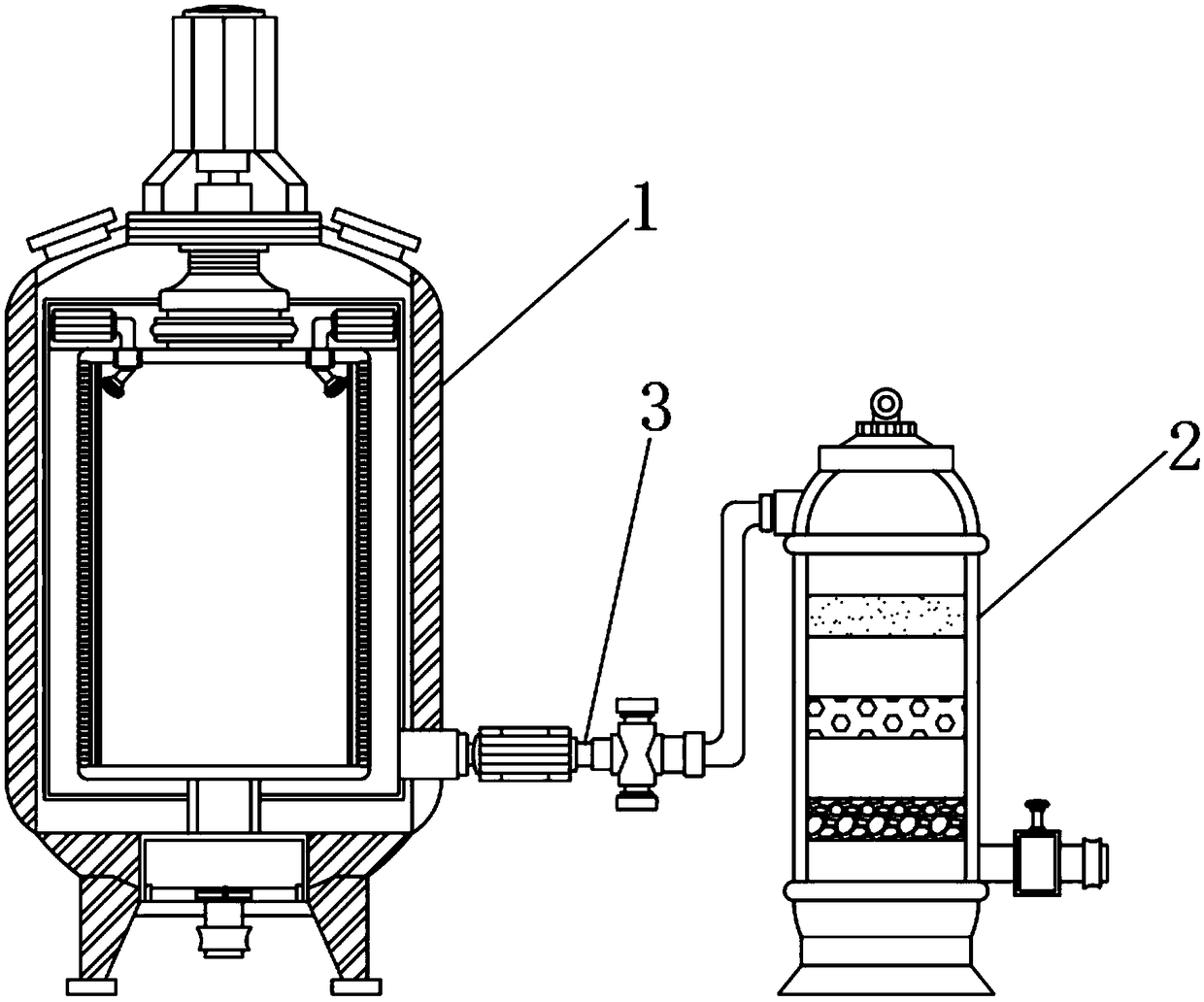

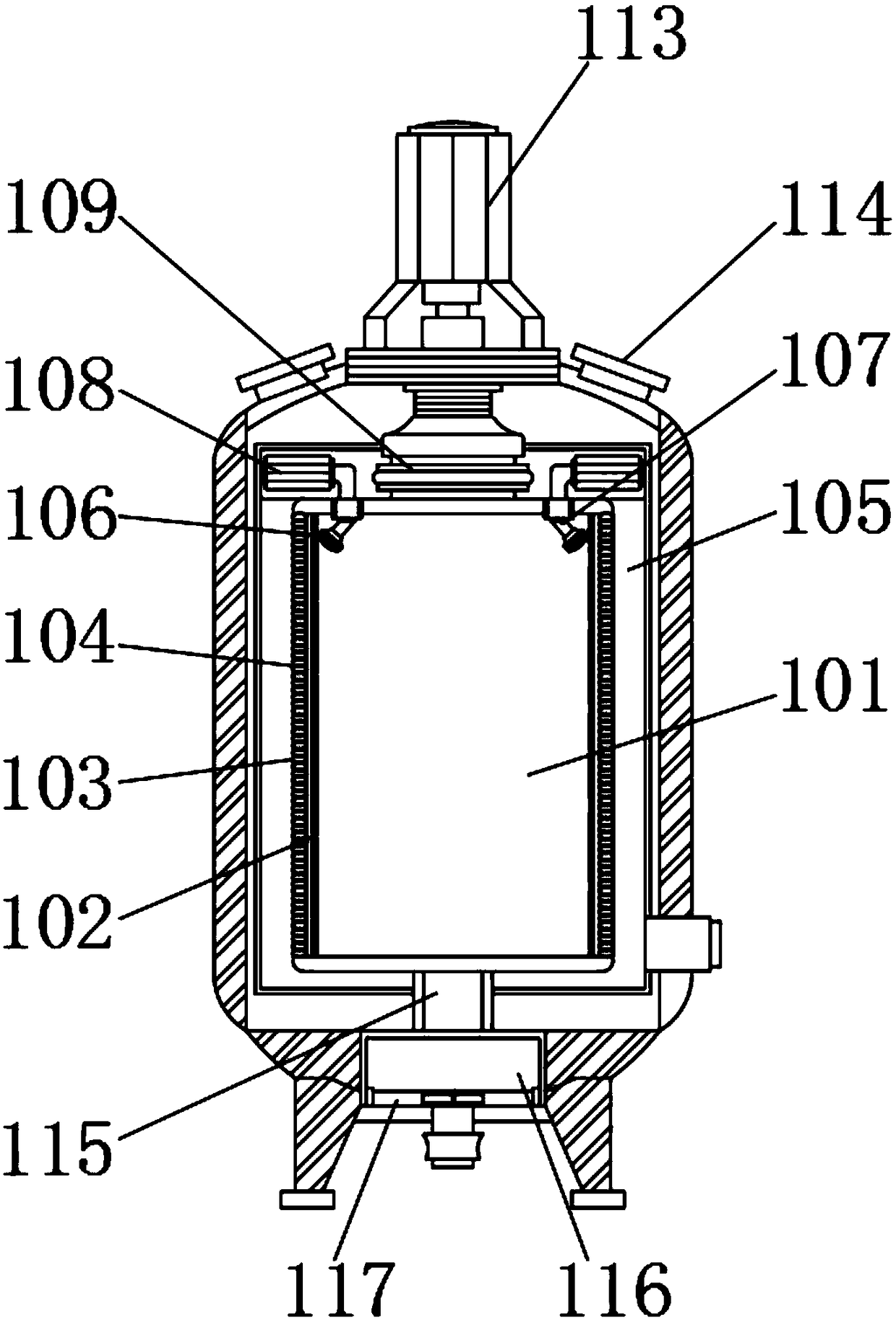

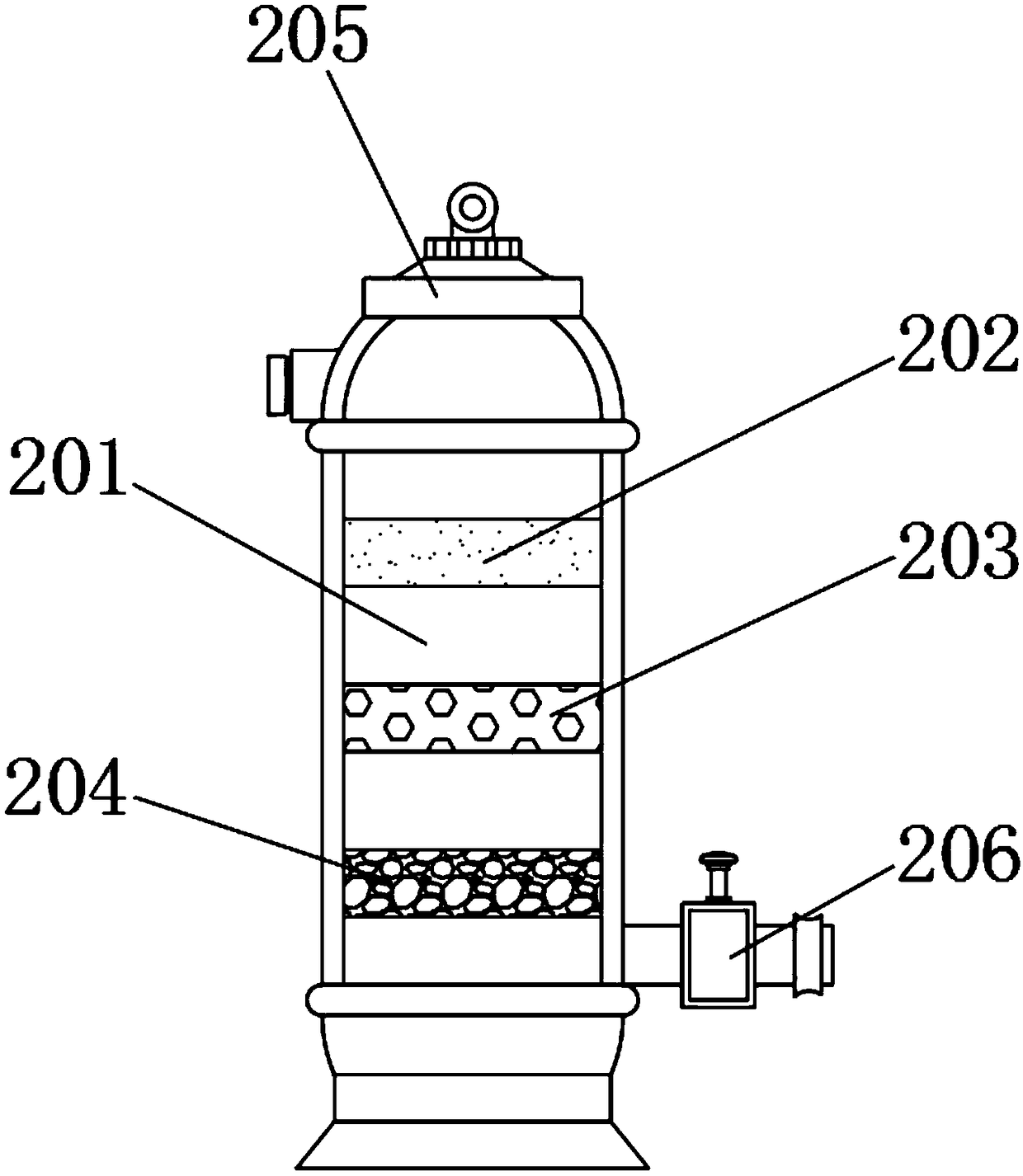

[0029] Example: such as Figure 1-6As shown, the present invention provides a technical solution, a kind of sewage separation equipment for water environment, including a sewage separation assembly 1, a sewage purification assembly 2 and a connection assembly 3, and the sewage separation assembly 1 and the sewage purification assembly 2 pass through The connection assembly 3 is sealed and connected. The dirt separation assembly 1 includes a separation chamber 101, a pollution-resistance protective film 102, a rotating centrifugal frame 103, a separation filter hole 104, a water storage chamber 105, an air distribution nozzle 106, an air delivery pipe 107, a collector Air pump 108, horizontal rotating disk 109, inner transmission shaft 110, joint convex teeth 111, fitting groove 112, power motor 113, raw material inlet 114, sewage channel 115, dirt collection box 116, automatic discharger 117, The pressure-bearing baffle 118, the drain hole 119, the connecting end plate 120, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com