Wide component window and high transduction coefficient ceramic material for piezoelectric energy collection and preparation

A technology of piezoelectric energy and piezoelectric ceramics, applied in the field of piezoelectric ceramic materials, can solve problems such as hindering the improvement of the conversion coefficient, increasing the difficulty of production technology, ensuring high conversion coefficient, etc., achieving good technology and industrial application prospects, design The method is novel and the effect of improving the conversion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

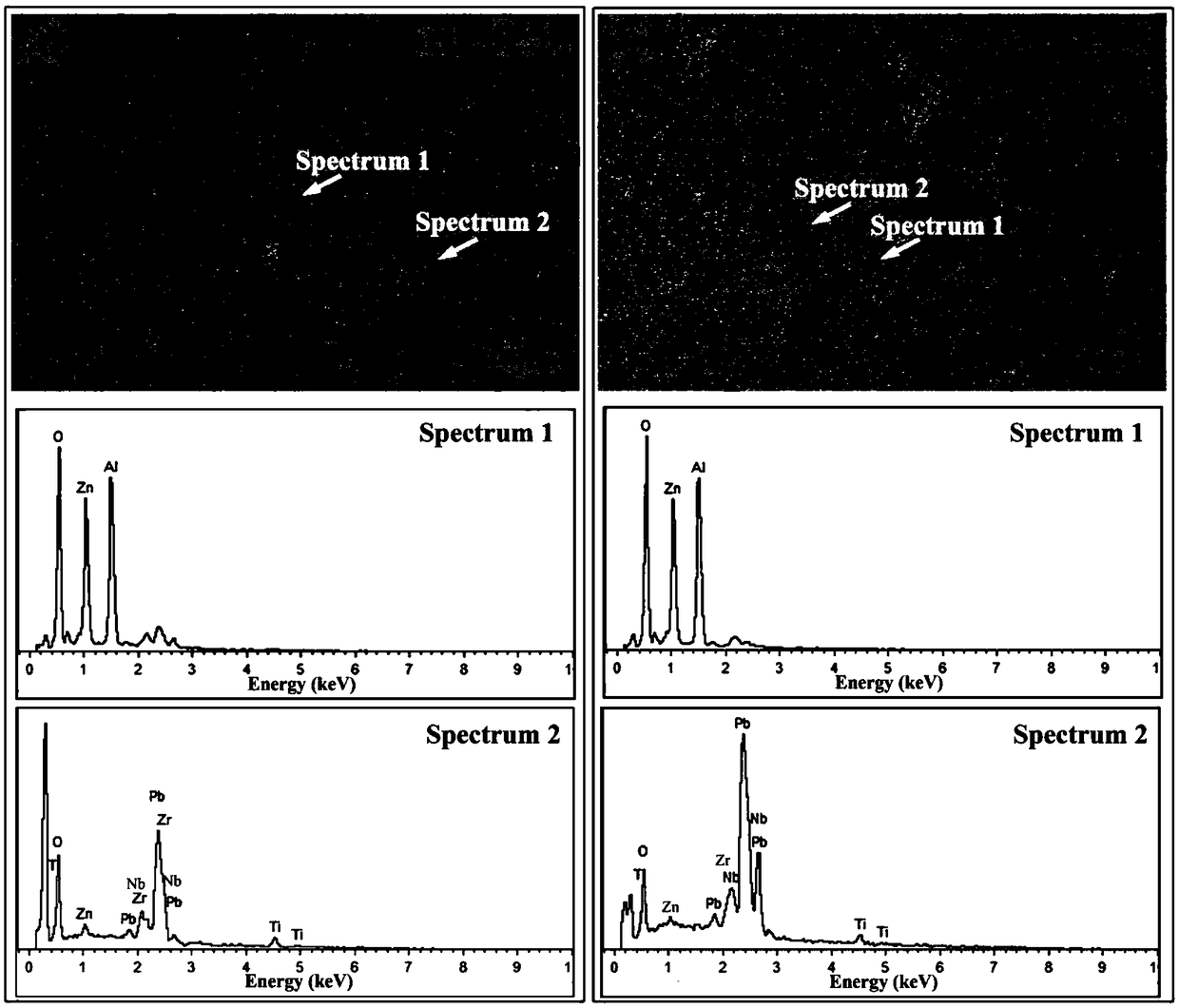

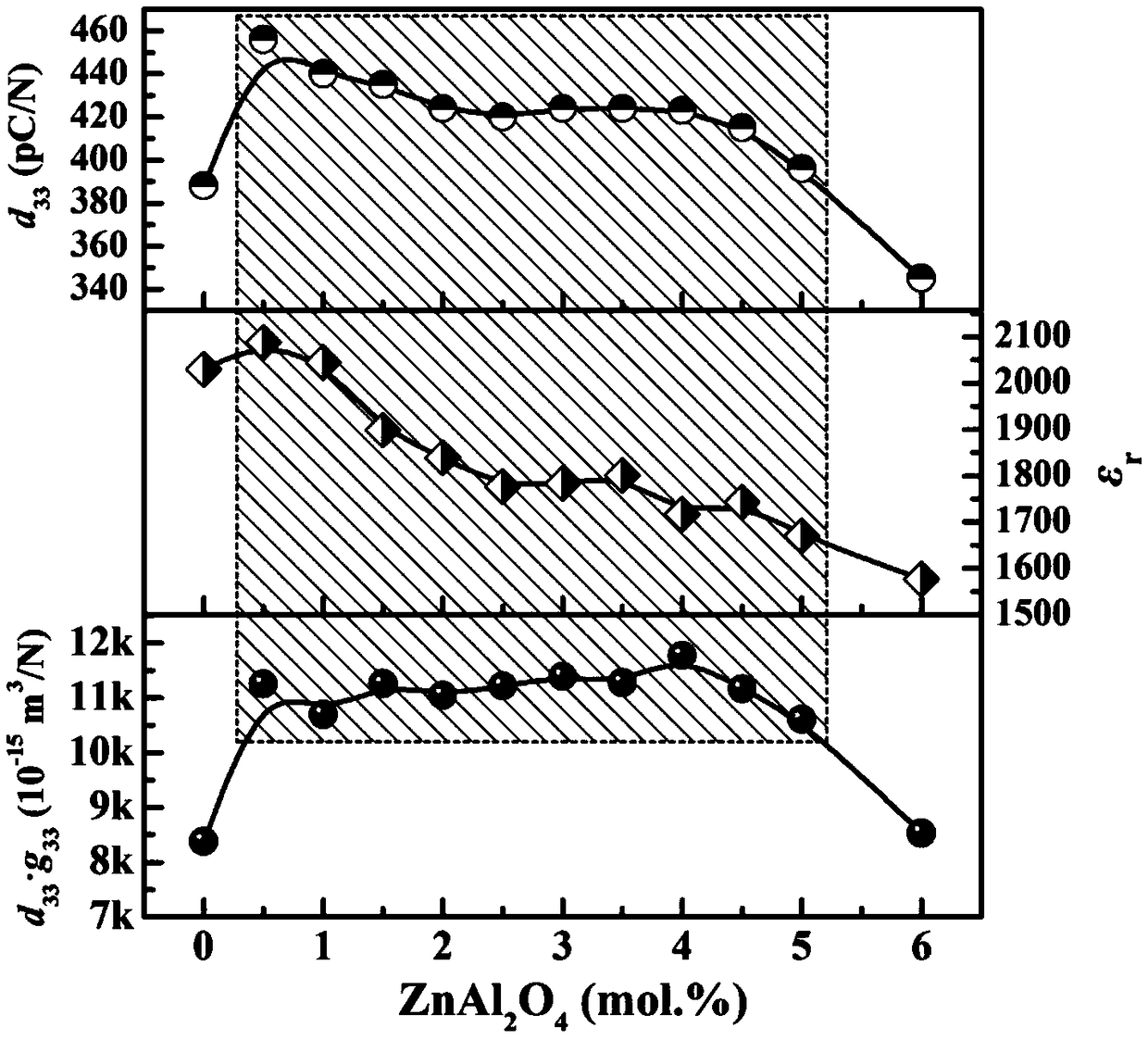

[0043] First according to the chemical formula of the matrix (Abbreviation 0.2PZN-0.8PZT) weigh Nb 2 o 5 , Pb 3 o 4 , ZrO 2 、TiO 2 and ZnO, and ball milled in ethanol for 12 hours. The mixture was dried and calcined at 850° C. for 2 hours, ball milled in ethanol and dried again to obtain 0.2PZN-0.8PZT powder. Then weigh 0.2PZN-0.8PZT powder, mix according to the ratio of 10g powder and 1.3mL binder, press the molded product at 100MPa, remove the binder at 560°C, and sinter at 1000°C for 2 hours to obtain Pure 0.2PZN-0.8PZT ceramics.

Embodiment 2

[0045] First according to the chemical formula of the matrix (Abbreviation 0.2PZN-0.8PZT) weigh Nb 2 o 5 , Pb 3 o 4 , ZrO 2 、TiO 2 and ZnO, and ball milled in ethanol for 12 hours. After the mixture was dried, it was calcined at 850°C for 2 hours, ball milled and dried in ethanol again, and the product was pre-calcined at 1000°C for 2 hours, and then ball milled and dried in ethanol again to obtain 0.2PZN- 0.8PZT matrix powder. Then according to the nominal composition of 0.2PZN-0.8PZT+0.50mol.% AlN, weigh 0.2PZN-0.8PZT and AlN respectively, and ball mill in ethanol for 12 hours. After the mixture is dried, the ratio of 10g powder to 1.3mL binder Mix and press the molding at 100MPa, remove the binder at 560°C, and sinter at 1150°C for 2 hours to obtain PZNZT / ZnAl 2 o 4 Composite ceramics.

Embodiment 3

[0047] According to the nominal composition of 0.2PZN-0.8PZT+1.00mol.% AlN, weigh 0.2PZN-0.8PZT and AlN. Others are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com