Preparation of oxidized cellulose and application thereof to washing and drug loading

A technology for oxidizing cellulose and cellulose, which is applied in the fields of medicine and chemical industry, can solve the problems that cellulose needs to be improved, and achieve the effect of good hydrophilic and lipophilic or low toxicity and low particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

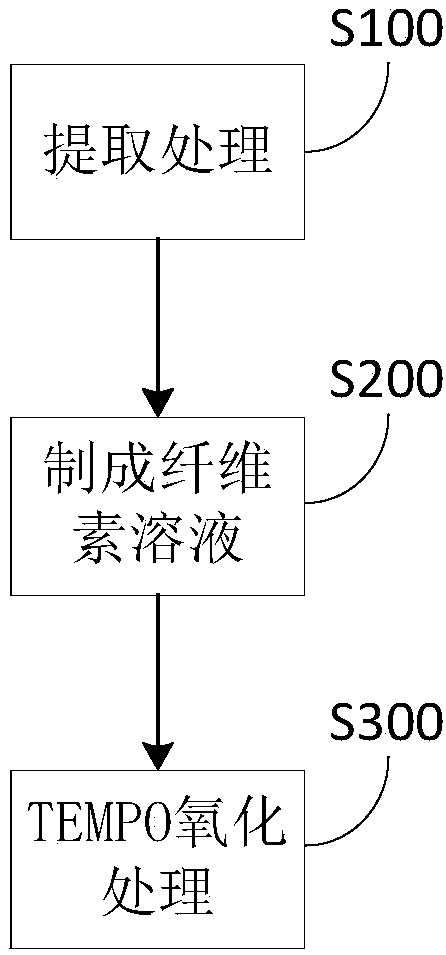

Method used

Image

Examples

Embodiment 1

[0088] In this example, oxidized cellulose was prepared as follows:

[0089] 1. Corn cob gas explosion residue:

[0090] Weigh 100g of corncobs with a balance, put them in a 2L beaker, add 1000ml of deionized water, completely submerge the corncobs, soak for 8 hours, drain the water, and explode with sulfuric acid steam. The explosion pressure is 0.9MPa, and the pressure is maintained for 5 minutes. The gas explosion residue was extracted with hot water at 80°C for 2 times, each time for 1 hour, and the residue was washed with water until it was neutral. Freeze-dried for later use.

[0091] 2. Extraction of cellulose

[0092] Weigh 10mg of the gas explosion residue, add 7.5ml of 2% sodium hydroxide, and heat at 160°C for 2h. After the reaction is completed and cooled, solid-liquid separation is carried out, and the solid is washed with deionized water until neutral, which is the extracted cellulose.

[0093] 3. TEMPO oxidation

[0094] (1) Weigh 1g of cellulose and dissol...

Embodiment 2

[0103] In this example, the effect of the amount of NaOH added in step (4) was investigated.

[0104] Specific operation:

[0105] (1) Prepare oxidized cellulose according to the method of Example 1, wherein the amount of NaOH added in step (4) is 3.75 mL, 6.25 mL and 12.5 mL respectively, to obtain oxidized cellulose 1, 2 and 3.

[0106] (2) Dissolve 2 mg of oxidized cellulose in 2 mL of water and observe its solubility. The results are as follows: Figure 5 shown.

[0107] It can be seen that the solubility of 3.75mL is poor, and as the amount of sodium hydroxide increases, the solubility of oxidized cellulose increases gradually.

[0108] (3) Carry out contact angle experiment with oxidized cellulose 2 and 3, specifically as follows:

[0109] The contact angle was measured by the tablet method. Weigh the cellulose, oxidized cellulose 2 (DO50) and oxidized cellulose 3 (DO100) obtained in the step (2) of Example 1 in equal amounts (40 mg), and after fully drying, press it...

Embodiment 3

[0113] In this example, the effect of the amount of TEMPO added was investigated.

[0114] Specific operation:

[0115] (1) Nanocellulose was prepared according to the method in Example 1, wherein the amount of TEMPO added was 0.05-0.10 g to obtain oxidized cellulose.

[0116] (2) Calculate the yield of oxidized cellulose based on the following formula:

[0117] Oxidized cellulose yield (%)=100%×the mass of oxidized cellulose obtained in step (7) / 1g.

[0118] The result is as Figure 7 shown. It can be seen that when the amount of TEMPO added is 0.008g, the effect is the best.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| body length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com