Precipitation-hardening martensite antibacterial stainless steel for medical surgical operation

An antibacterial stainless steel, precipitation hardening technology, applied in the field of stainless steel materials, can solve problems such as bacterial infection, achieve the effect of inhibiting bacterial proliferation and increasing antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

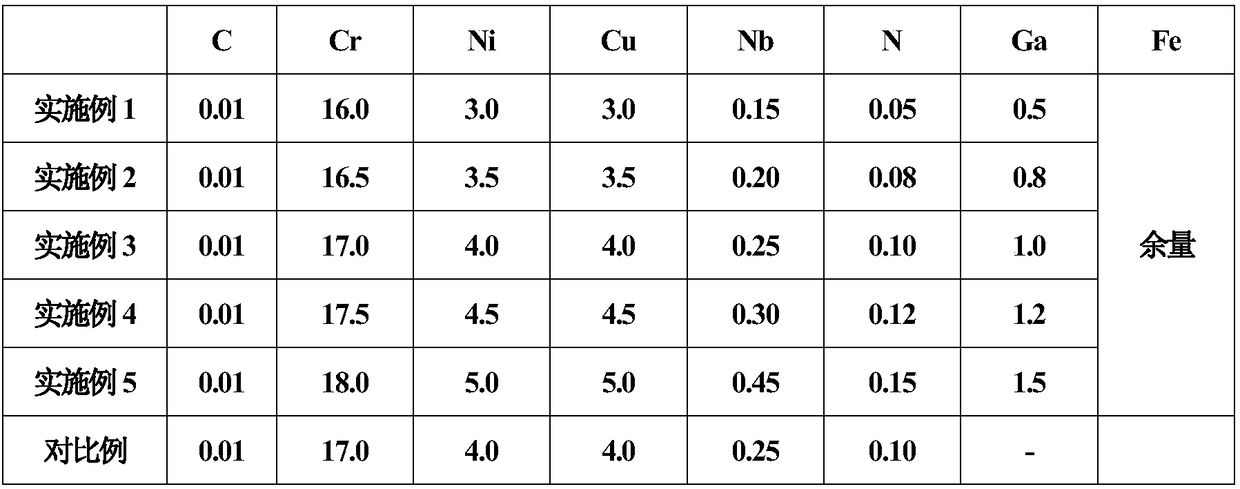

Embodiment 1

[0025] In this embodiment, the heat treatment process of precipitation hardening martensitic antibacterial stainless steel is:

[0026] Insulate at 1050°C for 1 hour, cool to room temperature with water, make the gallium and copper in the steel supersaturated; then hold at 480°C for 6 hours to precipitate gallium-rich phase and copper-rich phase in the steel, and cool to room temperature in air.

[0027] According to "JIS Z 2801-2000 "antibacterial processed products - antibacterial test method and antibacterial effect", GB / T2591-2003 "antibacterial plastic antibacterial performance test method and antibacterial effect" and other standards, the new precipitation hardened martensite The antibacterial performance test of antibacterial stainless steel on typical bacteria, the results are:

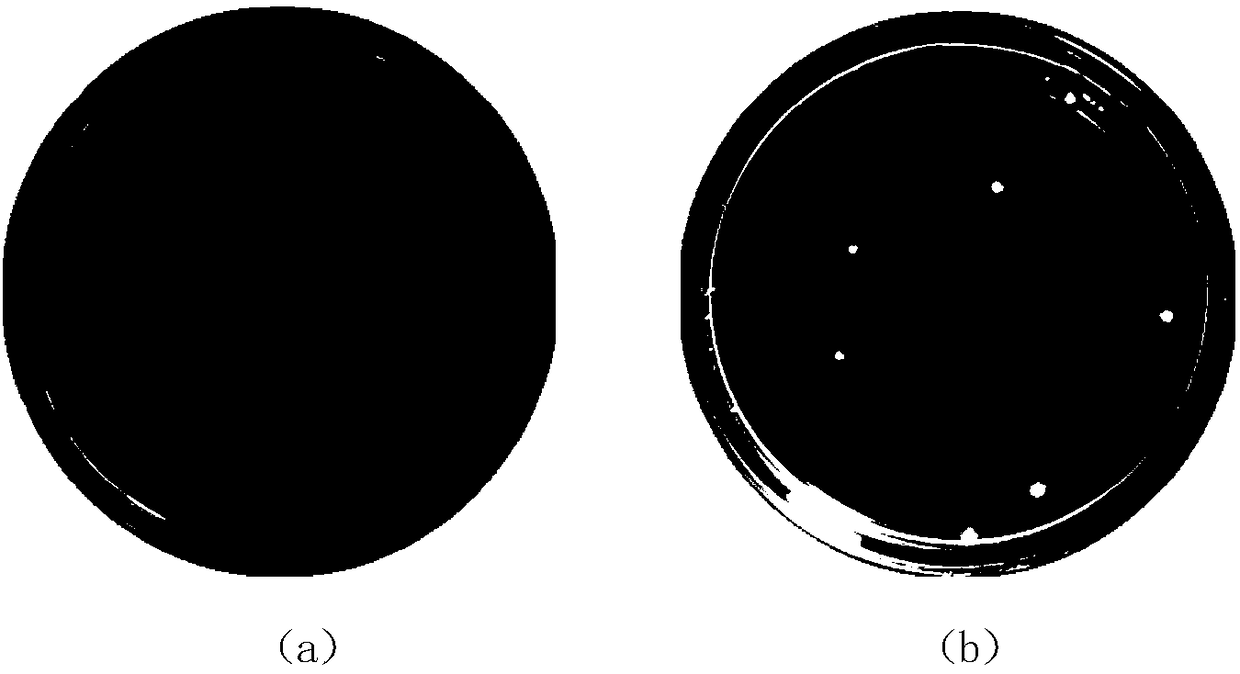

[0028] (1) Antibacterial rate against Eschericher Coli: ≥97.9%, antibacterial effect such as figure 1 shown;

[0029] (2) Antibacterial rate against Staphyococcus aureus: ≥96.9%.

Embodiment 2

[0031] In this embodiment, the heat treatment process of precipitation hardening martensitic antibacterial stainless steel is:

[0032] Insulate at 1000°C for 1 hour, cool to room temperature with water, and then hold at 450°C for 10 hours to precipitate gallium-rich phase and copper-rich phase with sufficient volume fraction in the steel, then cool to room temperature with water.

[0033] According to "JIS Z 2801-2000 "antibacterial processed products - antibacterial test method and antibacterial effect", GB / T2591-2003 "antibacterial plastic antibacterial performance test method and antibacterial effect" and other standards, the new precipitation hardened martensite The antibacterial performance test of antibacterial stainless steel on typical bacteria, the results are:

[0034] (1) Antibacterial rate against Eschericher Coli: ≥99.1%;

[0035] (2) Antibacterial rate against Staphyococcus aureus: ≥99.5%;

Embodiment 3

[0037] In this embodiment, the heat treatment process of precipitation hardening martensitic antibacterial stainless steel is:

[0038] Insulate at 1100°C for 2 hours, cool to room temperature with water, then hold at 650°C for 3 hours, and cool to room temperature in air.

[0039]According to "JIS Z 2801-2000 "antibacterial processed products - antibacterial test method and antibacterial effect", GB / T2591-2003 "antibacterial plastic antibacterial performance test method and antibacterial effect" and other standards, the new precipitation hardened martensite The antibacterial performance test of antibacterial stainless steel on typical bacteria, the results are:

[0040] (1) Antibacterial rate against Eschericher Coli: ≥99.7%;

[0041] (2) Antibacterial rate against Staphyococcus aureus: ≥99.8%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com