Soft pack hardened cigarette paper and manufacturing method thereof

A technology for cigarette wrapping paper and soft wrapping, which is applied in directions such as wrapping paper, wrapping paper, packaging, etc., can solve the problems of opening glue, paper stiffness of cigarette wrapping paper, and paper water absorption that cannot meet the production requirements of roll wrapping, and achieves a simple production method. , The effect of prolonging the storage time and reducing the folding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

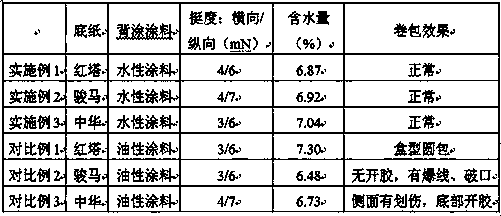

Embodiment 1

[0025] at 170g / m 2 The back of the Hongta coated white cardboard is coated with a layer of water-based paint to form a back coating; the surface of the Hongta coated white cardboard is coated with a layer of water-based glue to form an adhesive layer. The thickness of the adhesive layer is 10 μm; The transfer coating is coated on the transfer film, dried and aluminized, the square resistance of the aluminized layer is 1.0Ω, and the transfer film with the transfer layer is obtained; the transfer film with the transfer layer is covered on the adhesive layer, dried, The transfer film is peeled off to obtain soft-wrapped hardened cigarette wrapping paper; after the transfer film is peeled off, a waterproof layer is coated on the transfer layer.

Embodiment 2

[0027] at 170g / m 2 A layer of water-based paint is coated on the back of the horse-coated white cardboard to form a back coating; a layer of water-based glue is coated on the surface of the horse-coated white cardboard to form an adhesive layer, and the thickness of the adhesive layer is 20 μm; The transfer coating is coated on the transfer film, dried and aluminized, the square resistance of the aluminized layer is 2.0Ω, and the transfer film with the transfer layer is obtained; the transfer film with the transfer layer is covered on the adhesive layer, dried, The transfer film is peeled off to obtain soft-wrapped hardened cigarette wrapping paper; after the transfer film is peeled off, a waterproof layer is coated on the transfer layer.

Embodiment 3

[0029] at 170g / m 2 A layer of water-based paint is coated on the back of the Zhonghua coated white cardboard to form a back coating; a layer of water-based glue is coated on the surface of the Zhonghua coated white cardboard to form an adhesive layer, and the thickness of the adhesive layer is 30 μm; The transfer coating is coated on the transfer film, dried and aluminized, the square resistance of the aluminized layer is 3.0Ω, and the transfer film with the transfer layer is obtained; the transfer film with the transfer layer is covered on the adhesive layer, dried, The transfer film is peeled off to obtain soft-wrapped hardened cigarette wrapping paper; after the transfer film is peeled off, a waterproof layer is coated on the transfer layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com