Laminated condenser

A condenser and laminated technology, applied in the field of condensers with laminated structure, can solve the problems of affecting the compactness and installation and arrangement, increasing the overall space of the condenser, and bending many pipelines, so as to reduce the process cost. Requirements and costs, saving space, and meeting basic needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with drawings and embodiments.

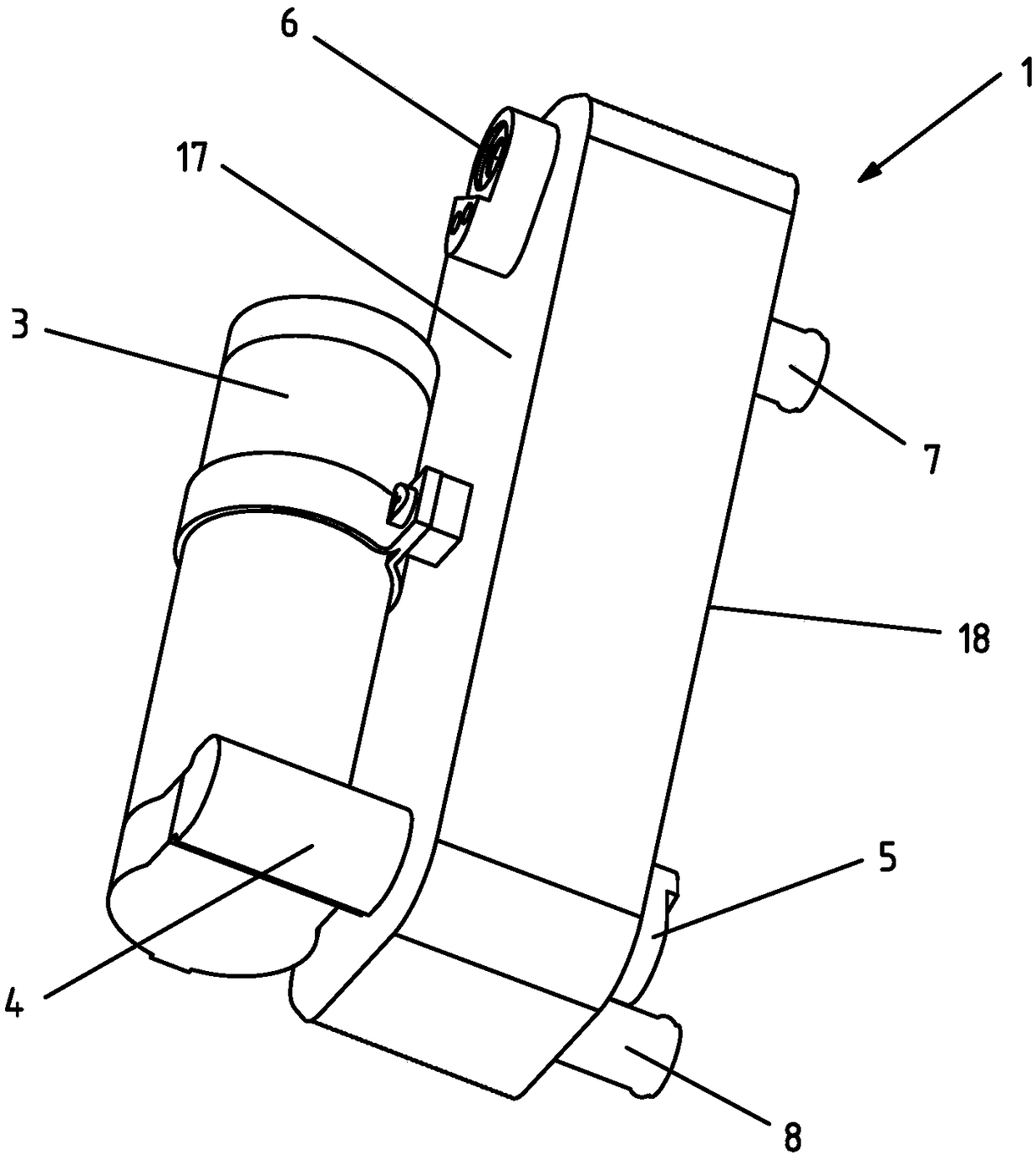

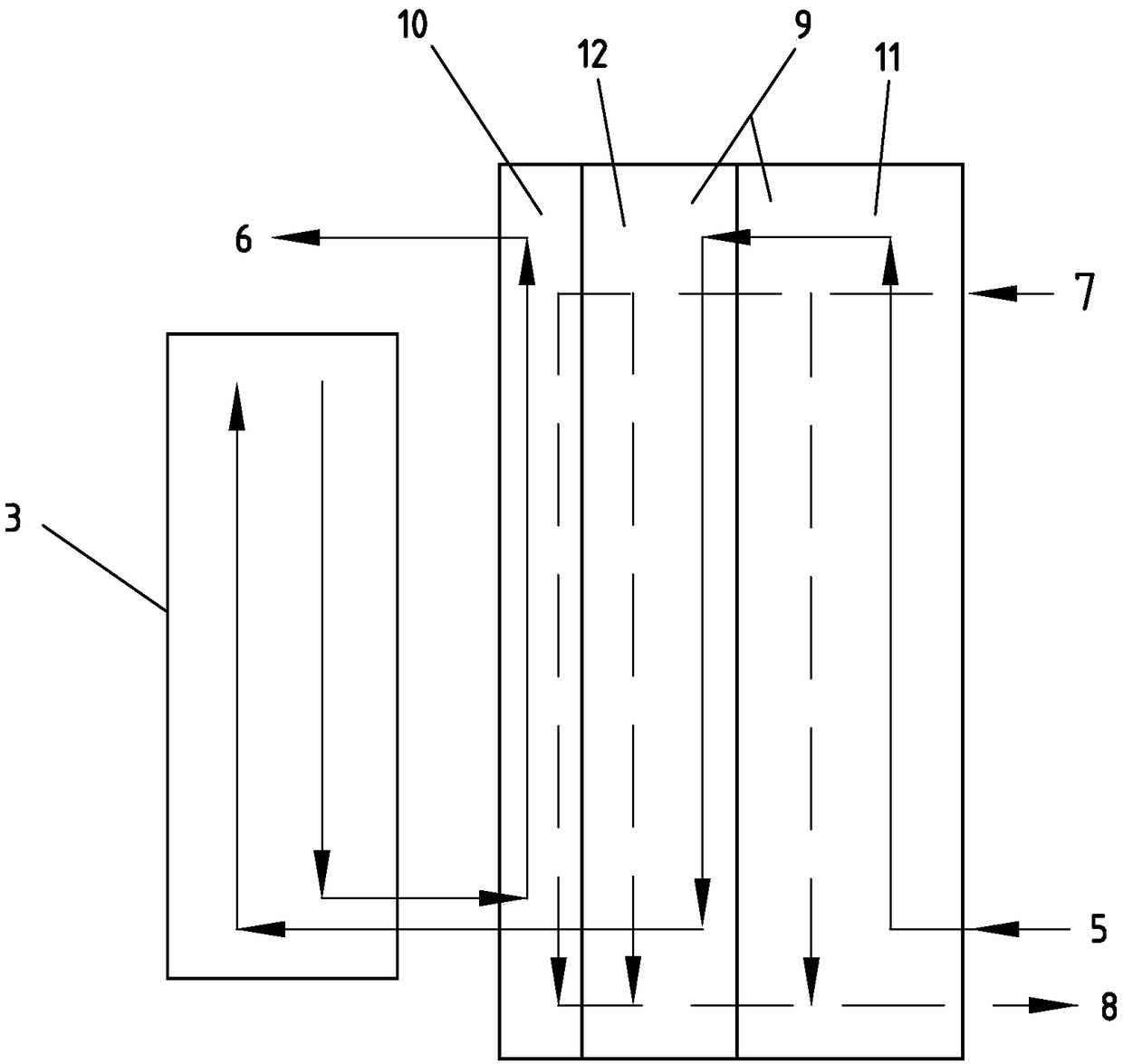

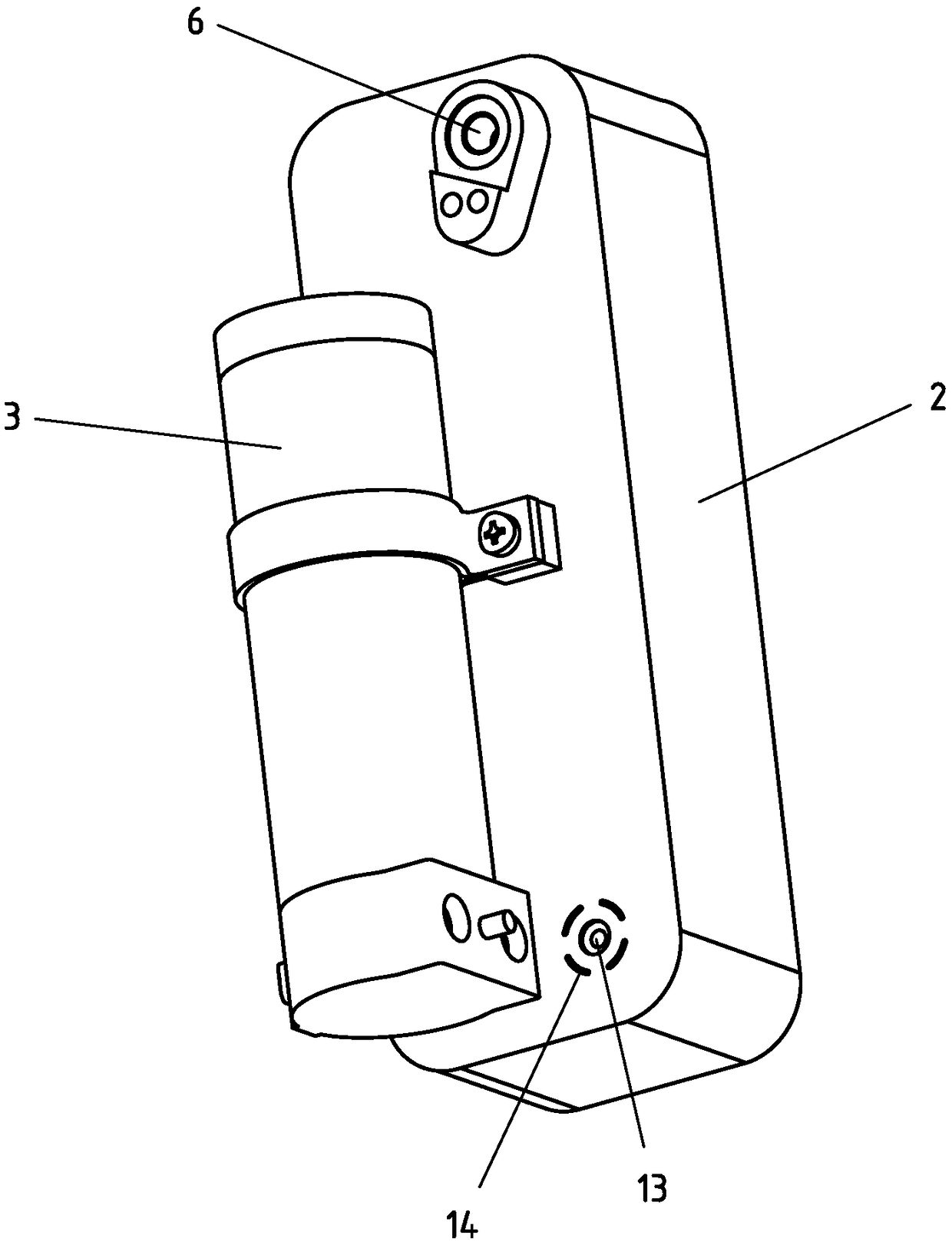

[0061] refer to Figure 1 to Figure 7 , a laminated condenser 1 of the present invention includes a condenser core 2 , a dry accumulator 3 and a deflector 4 . The condenser core 2 is formed by stacking a plurality of corrugated plates, and the inner cavity formed by stacking two adjacent corrugated plates constitutes a heat exchange channel 19, and the heat exchange channel 19 includes alternately arranged refrigerant channel and coolant channel, the refrigerant channel includes a condensing section 9 and a subcooling section 10 .

[0062] The condenser core includes a bottom plate 17 and a top plate 18 . The top of the bottom plate 17 is provided with a refrigerant outlet 6, the bottom of the bottom plate 17 is provided with a drainage channel 13 and a drainage hole 14, and the bottom of the top plate 18 is provided with a refrigerant inlet 5 and a coolant outlet 8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com