Light shielding sheet and lens

A shading sheet and lens technology, applied in the field of optical imaging, can solve the problems affecting the quality and yield of the imaging lens, the reduction of the imaging quality of the imaging lens, the influence of thickness consistency, etc., so as to ensure the quality and yield of the lens, and reduce the stray light. , The effect of thickness consistency guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

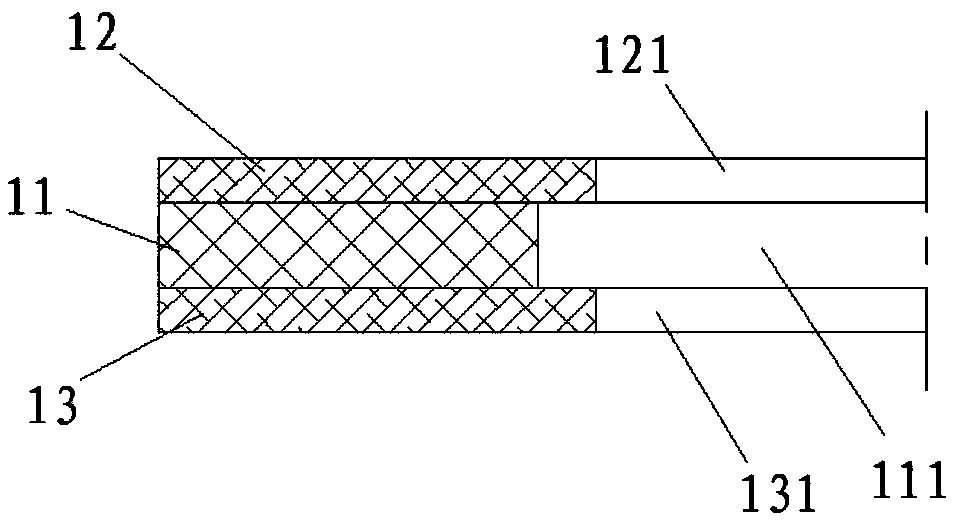

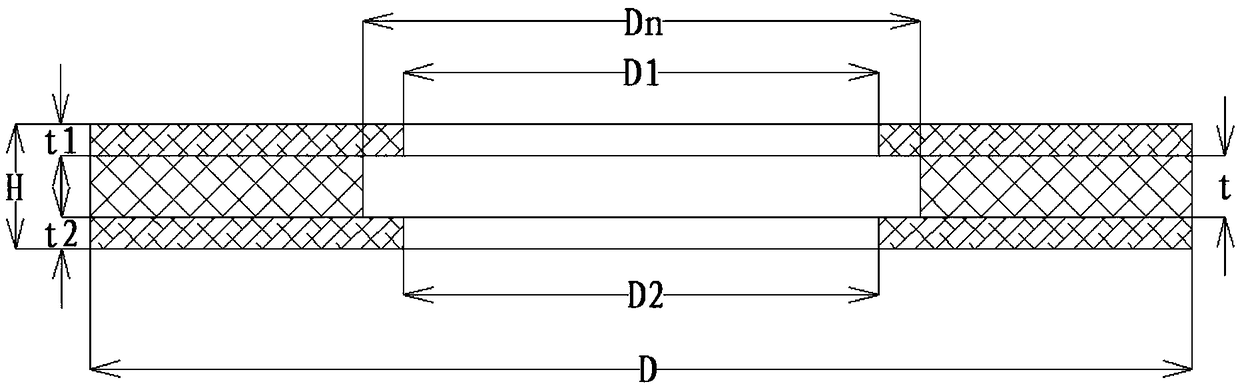

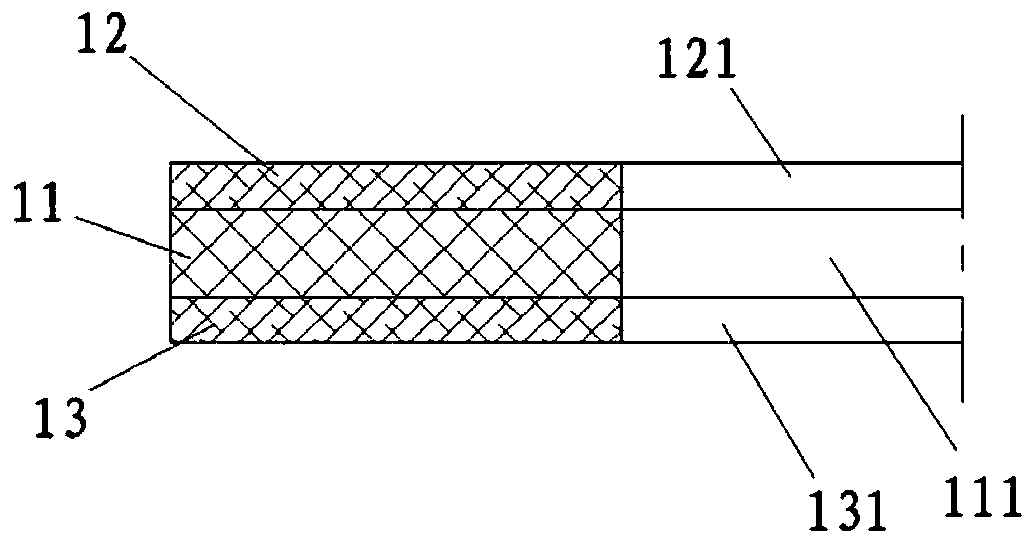

[0048] Such as figure 1 As shown, according to an embodiment of the present invention, a light-shielding sheet of the present invention includes: a base layer 11, a first surface layer 12, and a second surface layer 13. In this embodiment, the first surface layer 12 and the second surface layer 13 are respectively disposed on opposite sides of the base layer 11. A base layer through hole 111 is provided on the base layer 11, a first through hole 121 is provided on the first surface layer 12, and a second through hole 131 is provided on the second surface layer 13. The base layer through hole 111, the first through hole 121 and the second through hole 131 are coaxially arranged with each other. In this embodiment, the base layer 11, the first surface layer 12, and the second surface layer 13 are all thin film layers, and the first surface layer 12 and the second surface layer 13 are thin film layers mixed with wax materials. In this embodiment, the first surface layer 12 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com