Automatic adjusting device for optical lens and method thereof

An optical lens, automatic technology, applied in optics, optical components, instruments, etc., can solve the problems of difficult to guarantee accuracy, high cost, difficult technical promotion, etc., to improve assembly accuracy, eliminate lens center deviation error, and expand the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below with reference to the figures and examples.

[0044] The invention provides an optical lens automatic adjusting device and method.

[0045] 1. The optical lens automatic adjustment device is as follows:

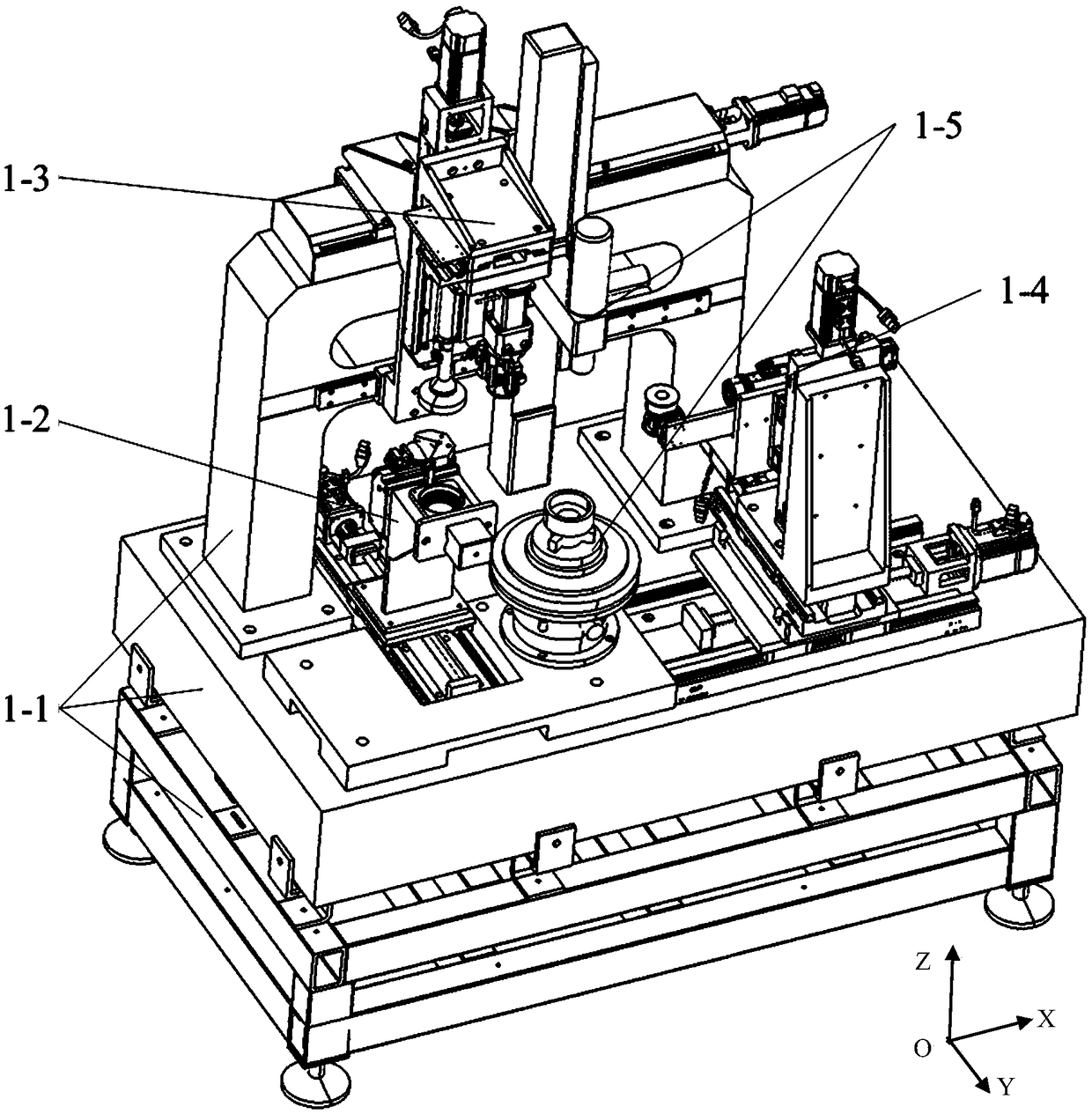

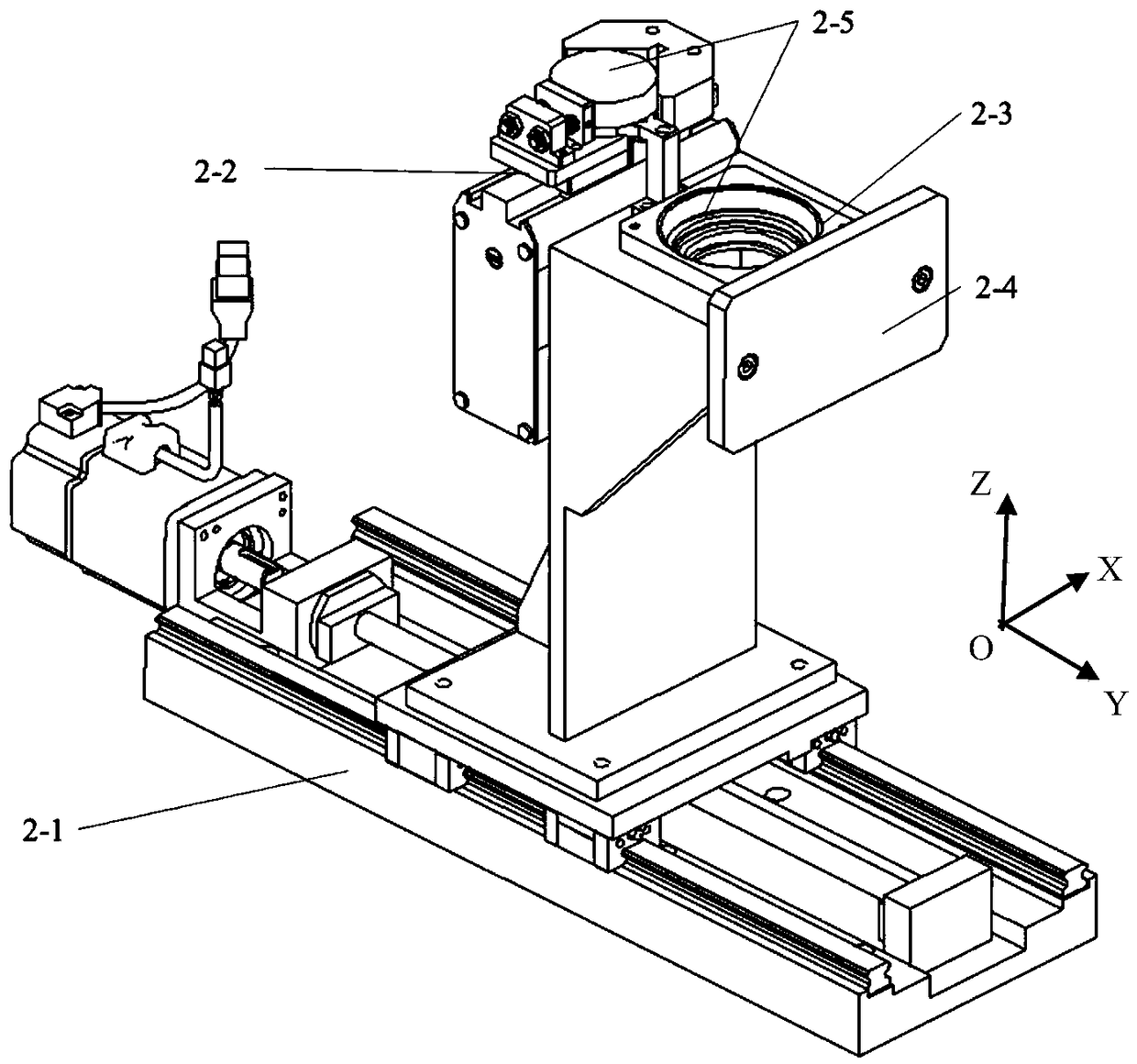

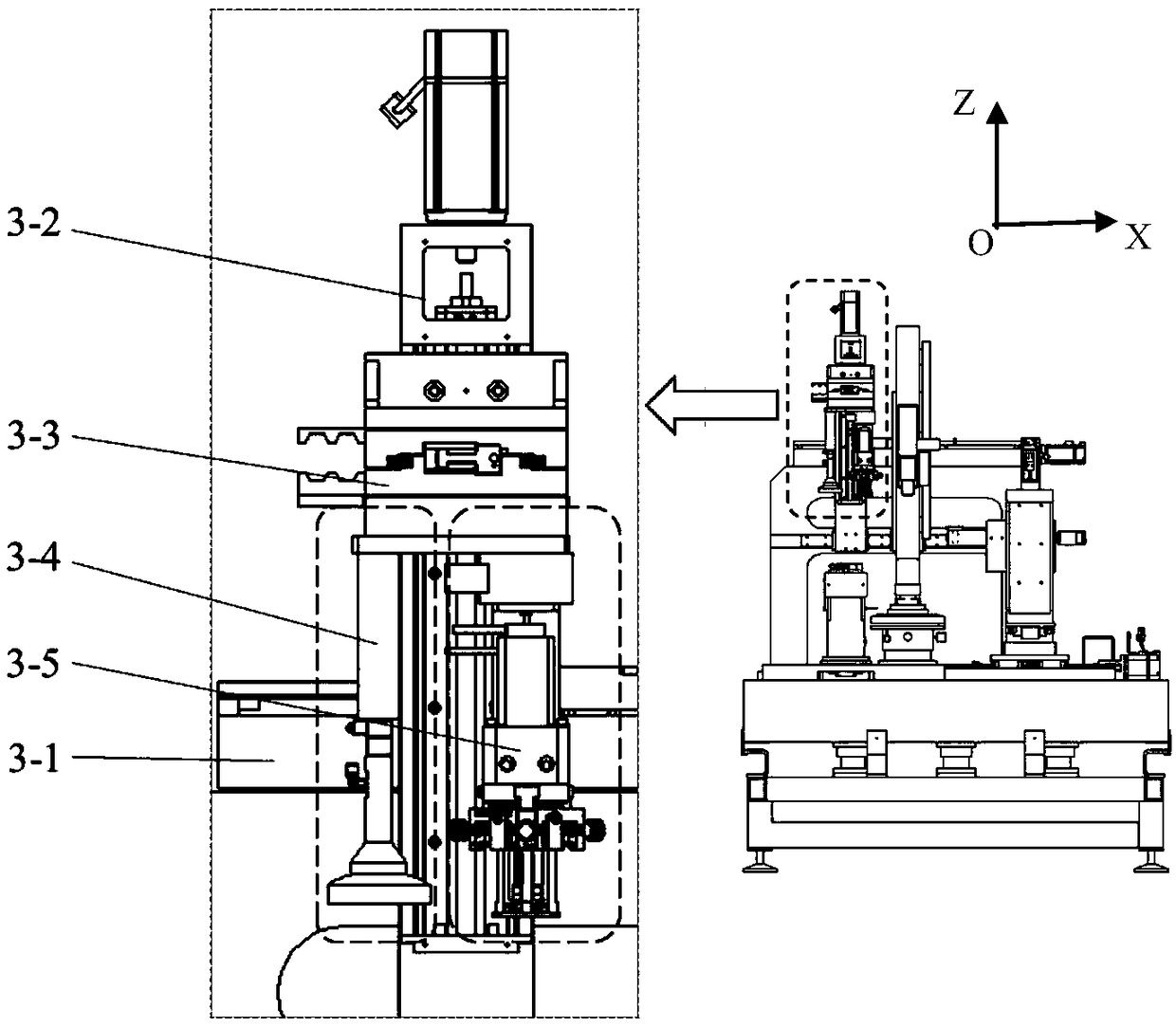

[0046] The structural diagram of the optical lens automatic assembly and adjustment device of the present invention is as followsfigure 1 shown. With the center of the plane where the device is located as the origin, establish the OXYZ coordinate system, define the OXY plane as the horizontal plane, and define the OXZ plane as the vertical plane. The optical lens automatic assembly and adjustment device of the present invention includes a control module, an auxiliary module 1-1, a feeding module 1-2, a clamping module 1-3, a coaxial alignment module 1-4 and an optical centering module 1-5, Under the control of the control module, the assembly and adjustment of the to-be-assembled part 2-5 and the lens barrel is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com