Solar cell sheet, and preparation method, preparation device, and solar cell thereof

A technology of solar cells and equipment, applied in the field of solar energy, can solve the problems of multi-light absorption loss, affecting the photoelectric conversion efficiency of solar cells, and poor performance of PN junction interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

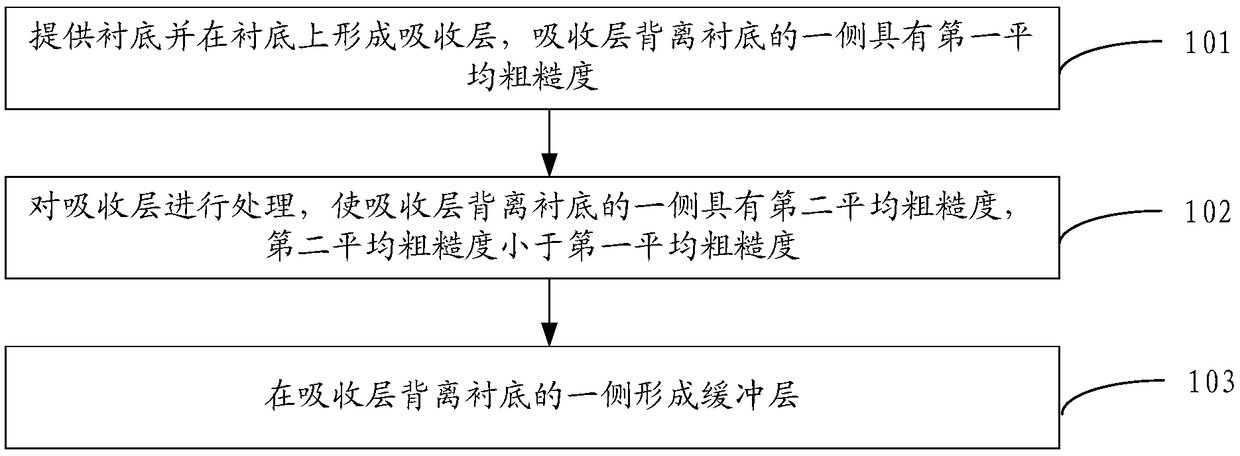

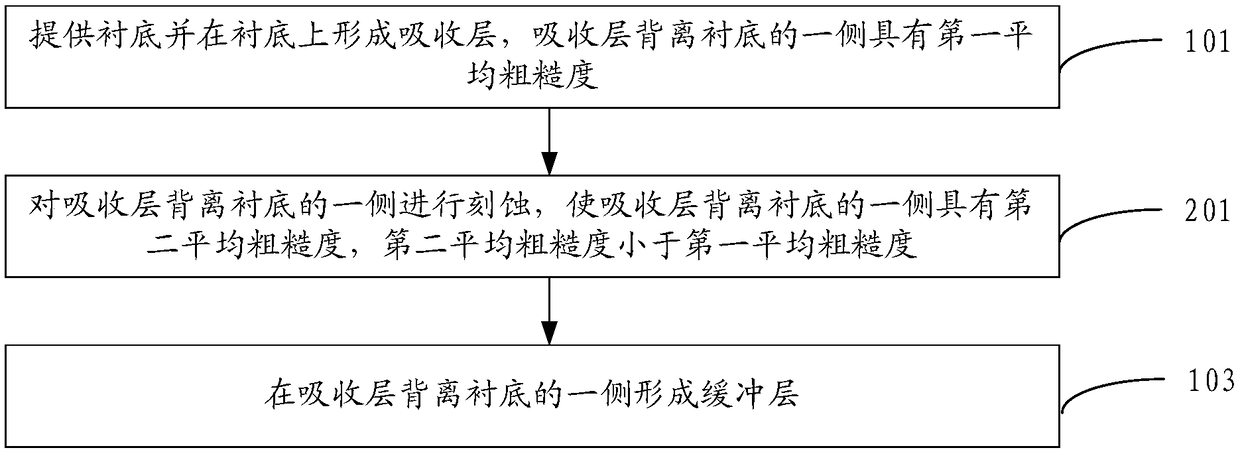

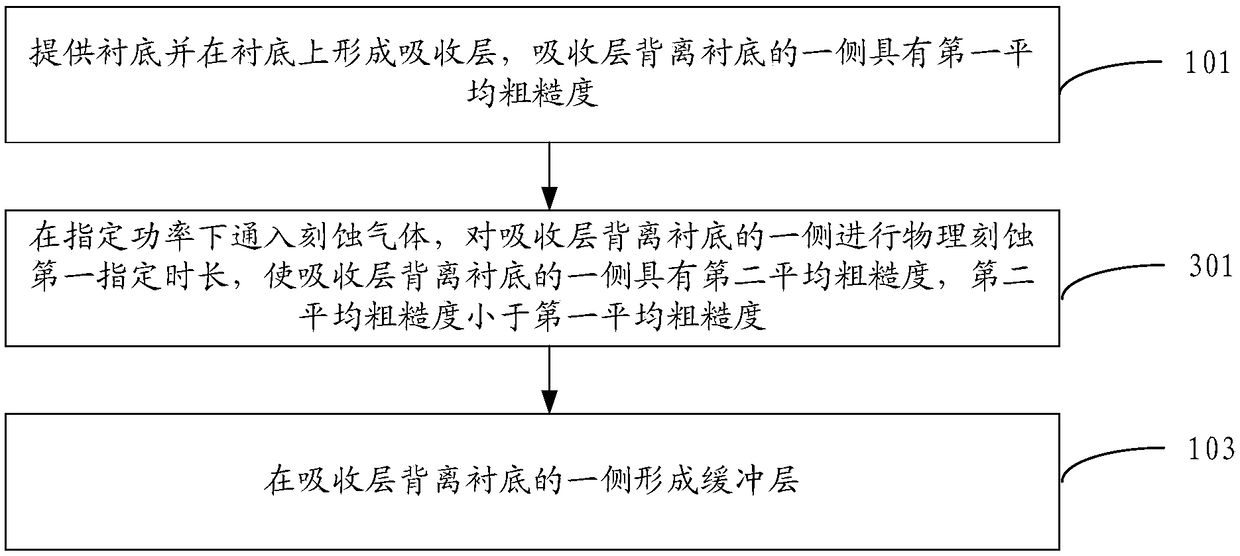

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0055] The inventors found that the existing solar cell buffer layer is thicker and the PN junction interface has more defect states, because the P-type absorber layer is generally polycrystalline, and high-efficiency thin-film solar cells require a grain size of 0.5-1um , the surface of the absorbing layer of this polycrystalline structure is relatively rough, so a relatively thick buffer layer is required to completely cover the rough surface of the absorbing layer, resulting in more light absorption loss, affecting the photoelectric conversion efficiency of the solar cell, and the rough absorbing The surface of the layer causes more defect states at the PN junction interface to form a recombination center, resulting in poor perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com