Individualized mammary gland prosthesis manufacturing method based on normal side mammary gland MRI image data

A production method and image data technology, which is applied in the field of production of individualized breast prosthesis, can solve problems such as differences in breast shape, impact on appearance, and lack of therapeutic effect, and achieve good resolution, good symmetrical shape, and good appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

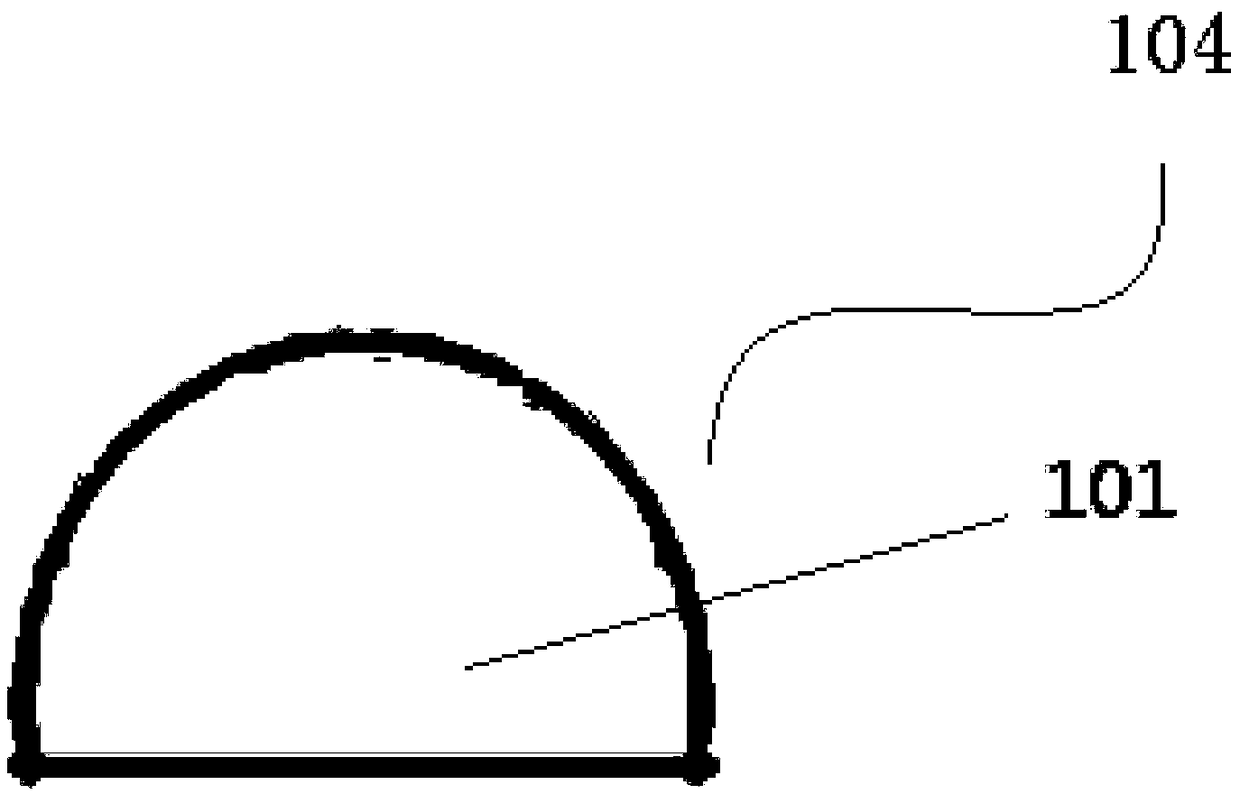

[0036] The present invention provides a method for making an individualized breast prosthesis based on the MRI image data of the healthy breast, comprising the following steps:

[0037] The first step is to obtain the original 3D laser scanning data of the patient's breast (upright position, end-inspiration) through a 3D laser scanner, and carry out 3D modeling of the healthy breast according to the original 3D laser scanning data. The 3D modeling of the healthy breast includes the entire healthy breast. The lateral mammary glands, the front, outside, and back are the chest and abdomen wall, the side chest wall, and the skin of the back, and the inner side to the midline of the sternum.

[0038] The second step is to obtain the original MRI data of the healthy side breast through MRI (magnetic resonance imaging) scanning (prone position, end inspiratory), and use the midivi cloud platform to import the MRI raw data for three-dimensional modeling. The built model includes the en...

Embodiment 2

[0048] The first step to the third step are the same as in Example 1.

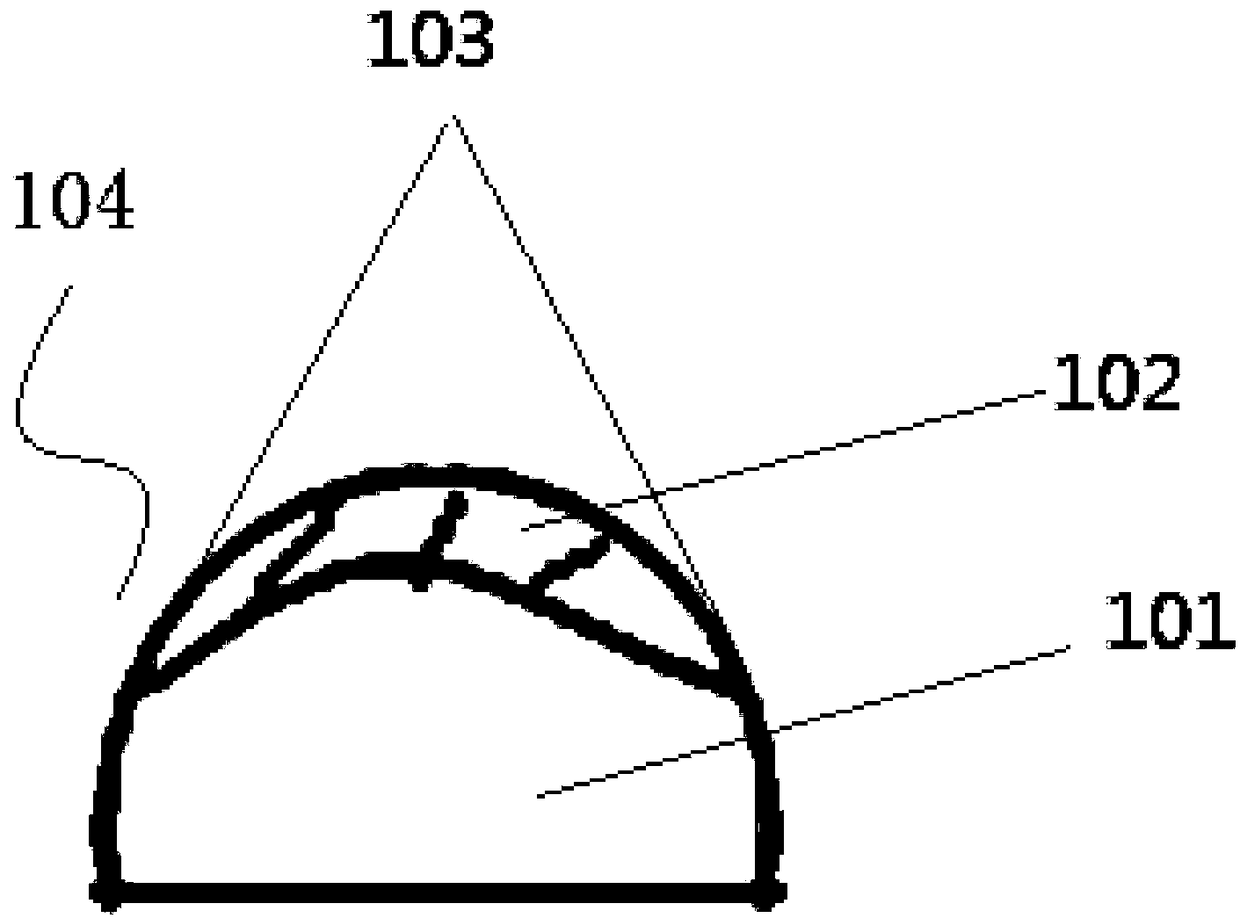

[0049] In the fourth step, first mark the position of the nipple-areolar complex area, and then obtain an individualized three-dimensional model of the breast prosthesis on the affected side that is symmetrical to the three-dimensional model of the healthy breast obtained in the third step according to the mirror image principle.

[0050] The specific operation steps are: import the 3D model of the healthy breast obtained in the third step into 3-matic software, use the mirror image command to obtain an individualized 3D model of the affected breast prosthesis that is symmetrical to the 3D model of the healthy breast, and mark the nipple and areola composite The location of the body area.

[0051] In the fifth step, according to the individualized 3D model of the breast prosthesis on the affected side obtained in the fourth step, use the FDM printer and use polylactic acid (PLA) as the raw material to 3D p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com