Gradient magnetic weight centrifugal screening chute, equipment and method for magnetic minerals

A technology of screening equipment and screening methods, applied in the fields of magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of reducing the recovery rate of magnetic minerals in concentrate products, the loss of magnetic minerals, and reducing the grade index of concentrates, etc. The effect of high sorting efficiency, avoiding loss, and screening quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

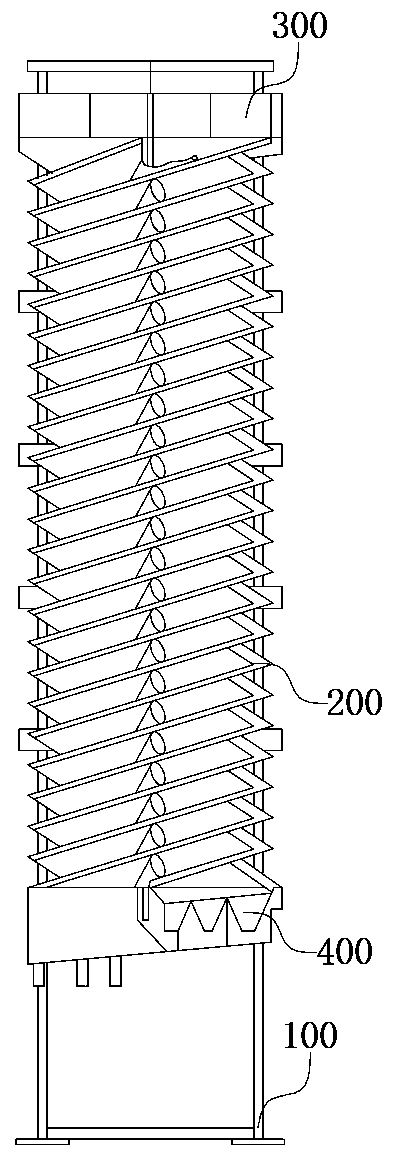

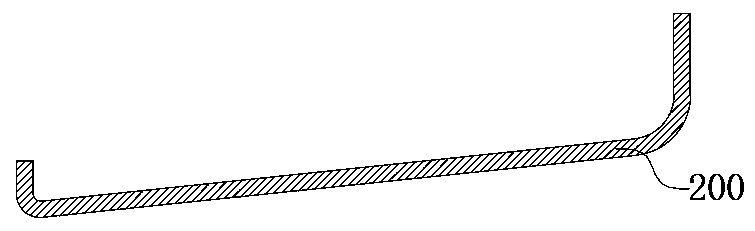

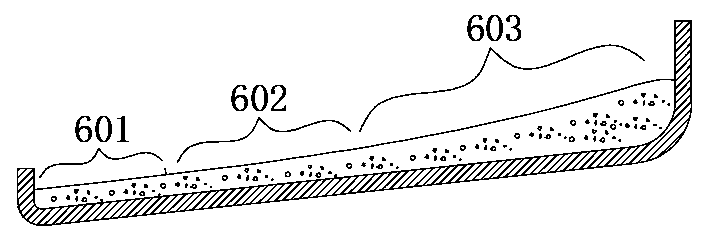

[0039] see Figure 5-Figure 12 , the gradient magnetic gravity centrifugal screening chute of a kind of magnetic mineral of the present invention comprises screening magnetic system 500 and spiral chute 200, and its screening magnetic system 500 comprises multiple groups of magnetic units 502 arranged in the same polarity along the cylindrical surface, and its magnetic unit 502 can be an electromagnet or a permanent magnet; its spiral chute 200 is coaxially located on the outside of the screening magnetic system, and in the radial direction of the spiral chute 200, the magnetic field strength of the screening magnetic system 500 acting on the spiral chute 200 is from the inside to the The outer divergence is weakened, forming a radial magnetic field gradient; take the intersection line of the spiral chute surface and the coaxial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com