Heating tin pan special for high-temperature tin

A technology of tin pot and high temperature, which is applied in the field of tin pot for high-temperature tin heating, can solve the problems of no special requirements for tin pot materials, unfavorable production efficiency, and constraints, and achieve the effects of light structure, improved production efficiency, and compact cavity size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited by the embodiments set forth herein. Rather, these embodiments are provided for more thorough understanding of the present disclosure and to fully convey the scope of the present disclosure to those skilled in the art.

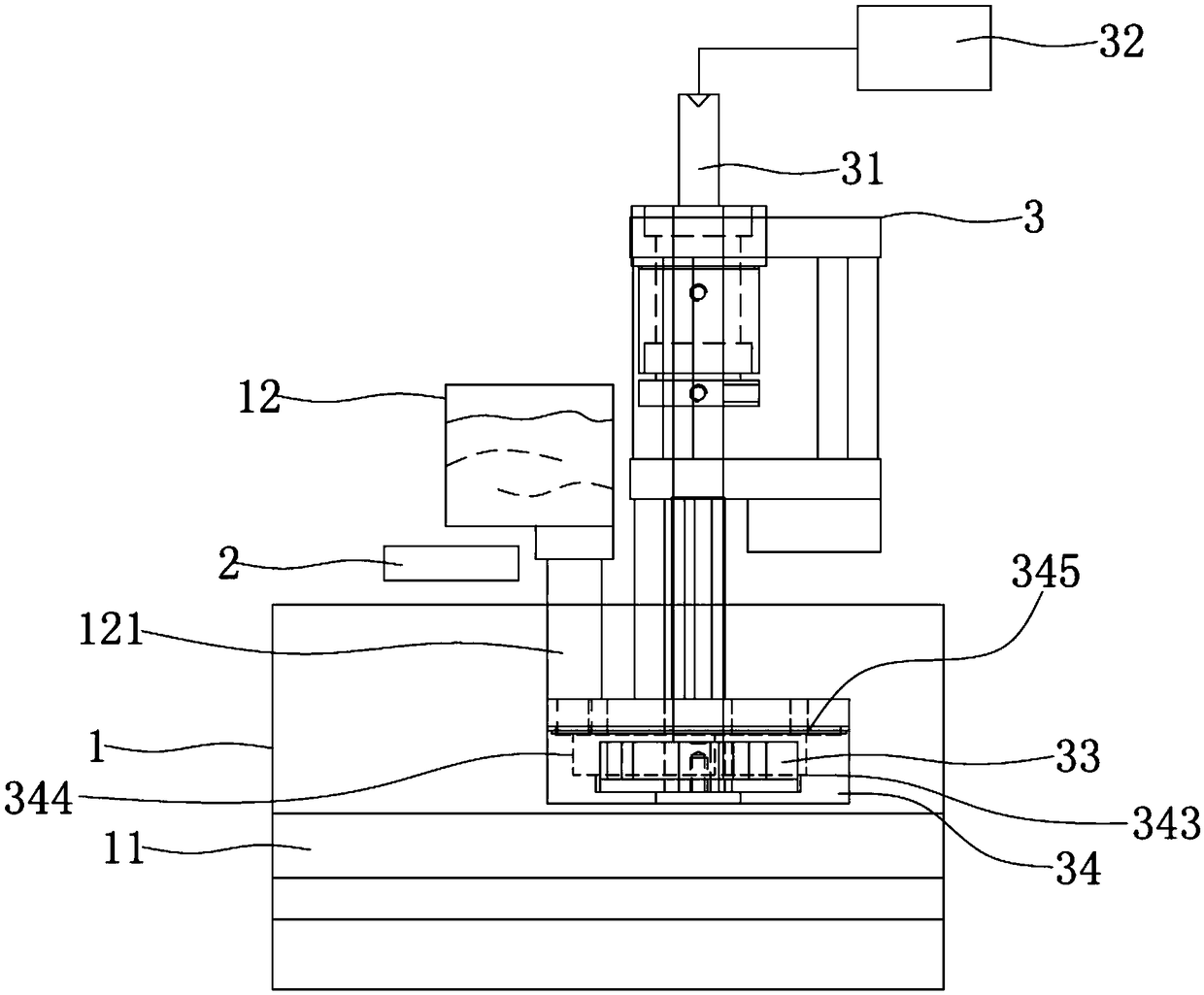

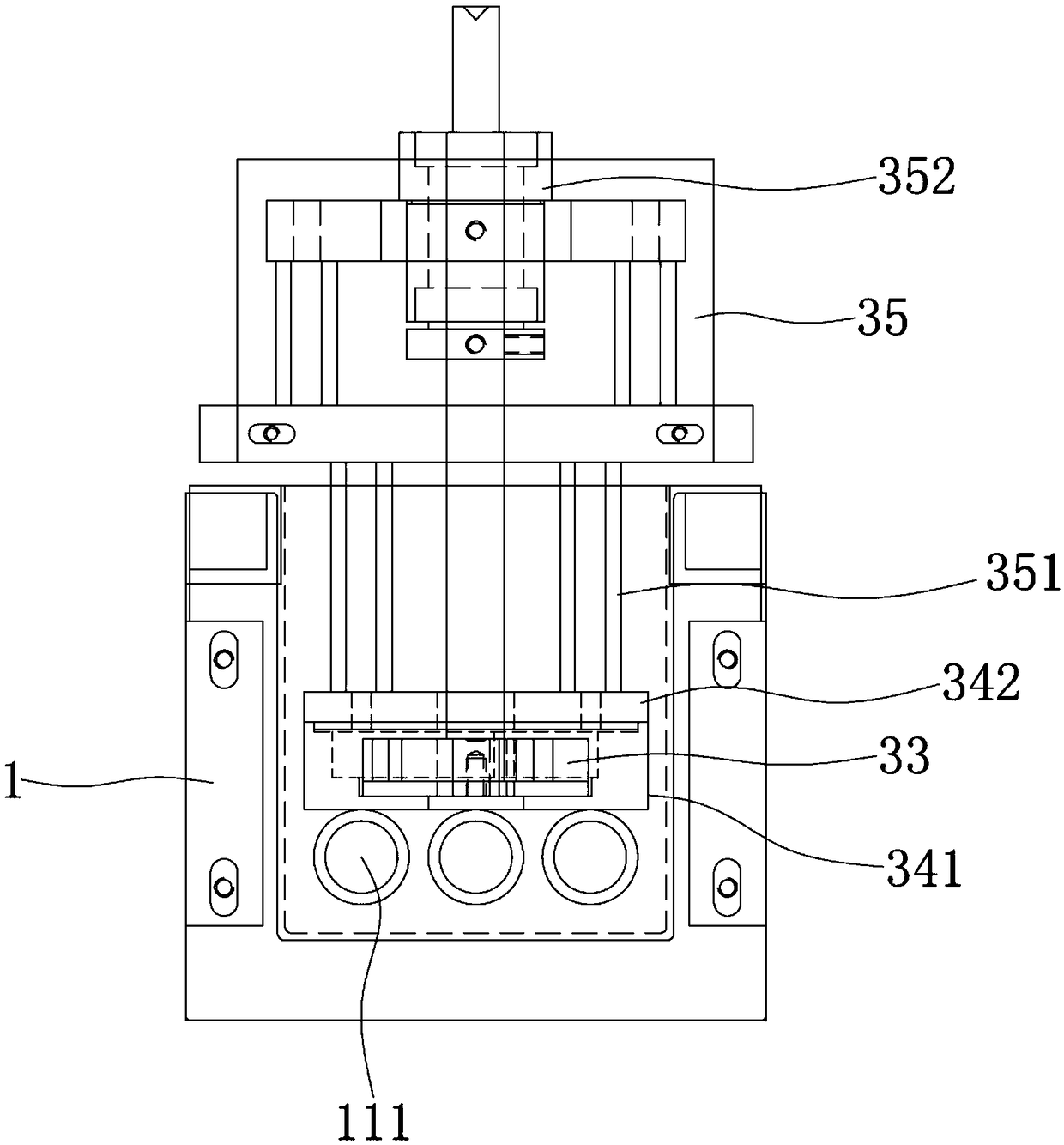

[0020] see Figure 1 to Figure 2 , the figure shows a special heating tin pot for high-temperature tin provided by the embodiment of the present invention, which includes a tin pot 1, the tin pot 1 is a titanium alloy tin pot, and the bottom of the tin pot 1 is provided with a heating component 11, It includes a plurality of heating rods 111, a tin cup 12 is installed on the tin pot 1, a feeding line 2 is arranged between the tin p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com