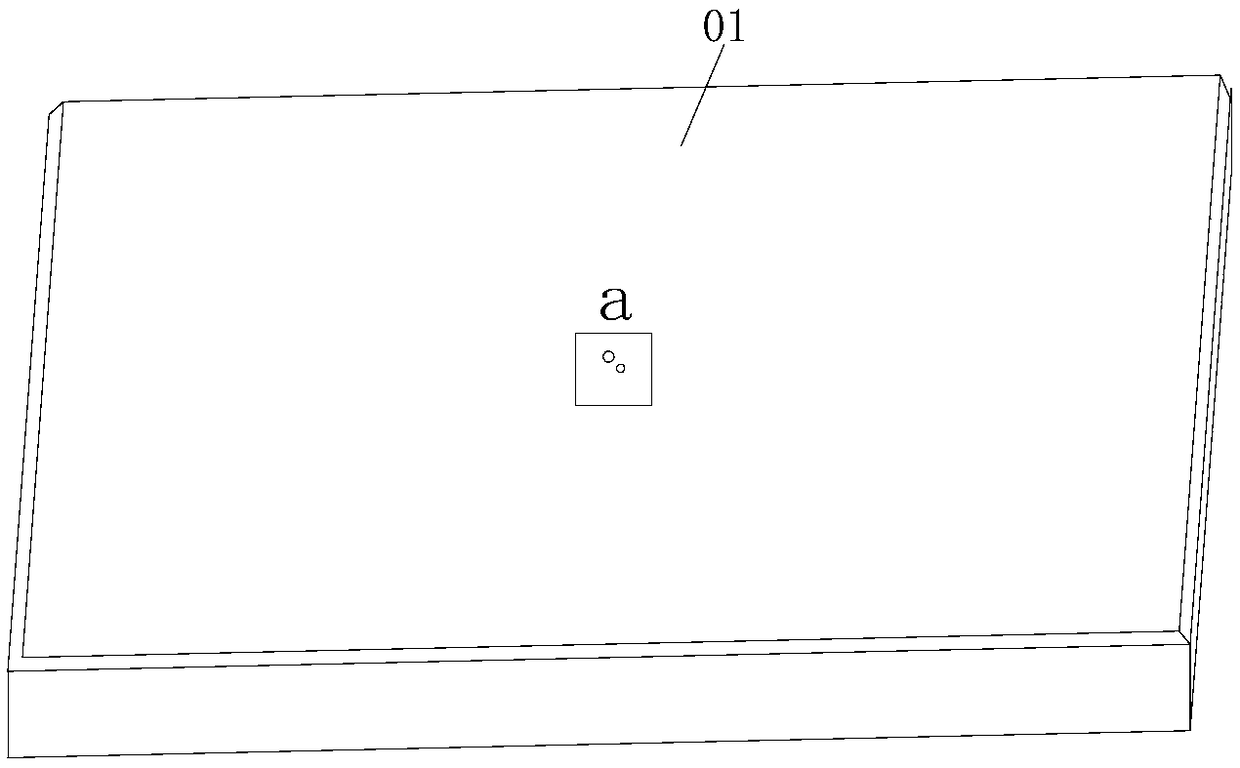

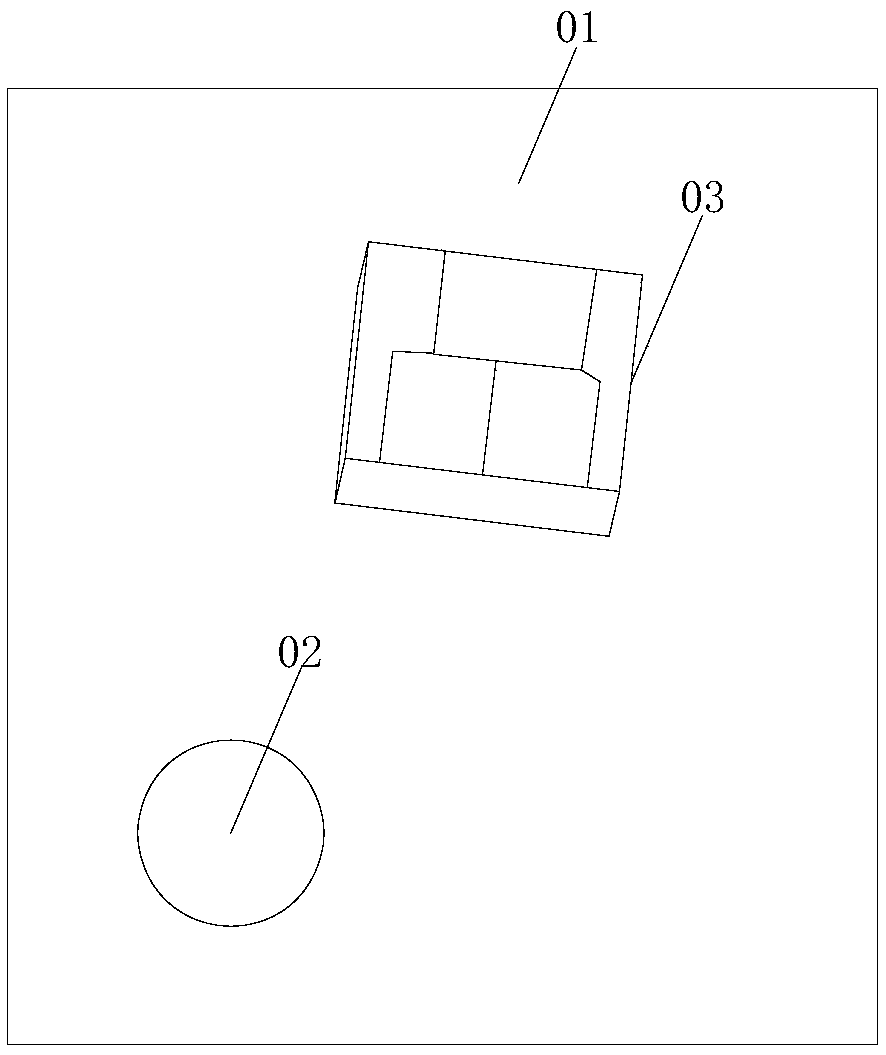

Laser eutectic welding device and application method

A eutectic welding and laser technology, applied in the field of optical modules, can solve the problem of easy oxidation of the laser carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

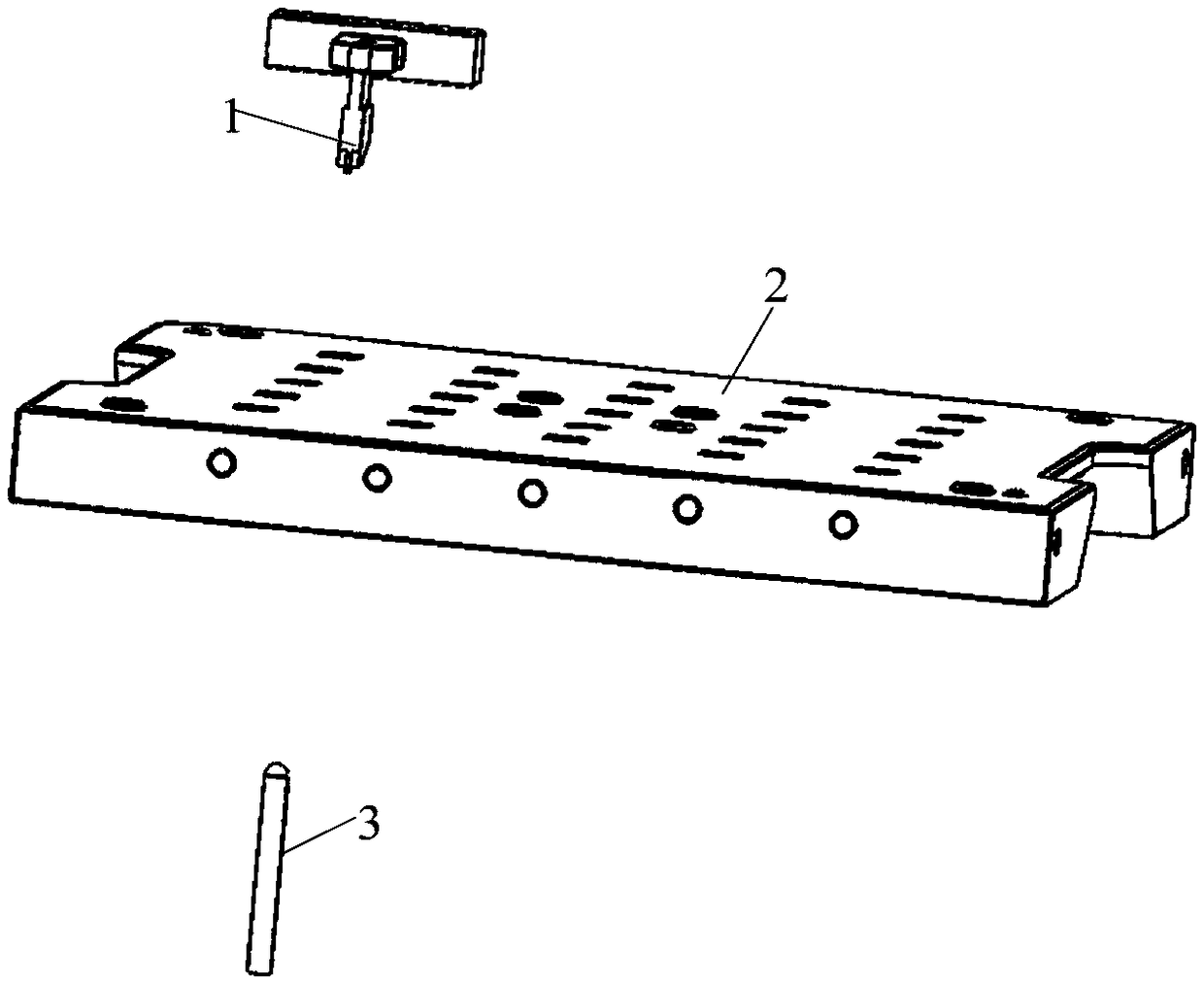

[0037] In the prior related art, a vacuum hole is provided on the upper surface of the tray in the laser eutectic welding device, and an electric heating wire is provided inside the laser carrier tray. When the laser carrier tray is used to position the laser carrier, the laser carrier is placed at the vacuum hole, and the laser carrier is adsorbed by the vacuum negative pressure at the vacuum hole, thereby realizing the positioning of the laser carrier. Since the laser carrier is positioned on the laser carrier tray through the vacuum hole, during the process of placing the laser on the laser carrier, the laser carrier will shift due to uneven force, thereby reducing the lamination accuracy of the laser and the laser carrier. In addition, after the laser is placed on the laser carrier, the electric heating wire starts to heat the laser carrier tray, and then heats the laser carrier, and finally realizes the welding of the laser and the laser carrier tray. However, due to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com