Method for prolonging service life of wood

A wood and lifespan technology, applied in wood treatment, wood heating, impregnating wood, etc., can solve problems such as weakening mechanical quality and service life, affecting appearance, mold, etc., to improve adsorption and fixation capacity, enhance market competitiveness, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

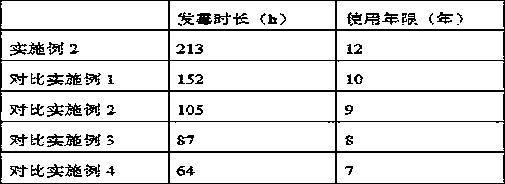

Examples

Embodiment 1

[0027] A method for prolonging the service life of wood, comprising the steps of:

[0028] (1) Cutting cleaning treatment:

[0029] Cut the wood first, and then wash the cut wood with water for later use;

[0030] (2) Steam explosion treatment:

[0031] Put the wood treated in step (1) into the steam explosion tank for steam explosion treatment. Firstly, water vapor with a temperature of 103°C is introduced into the steam explosion tank, and the pressure in the steam explosion tank is increased to 0.38MPa. After heat preservation and pressure treatment for 12 minutes, quickly unload the steam explosion tank to normal temperature and pressure, and finally take out the wood and let it cool down to room temperature for later use;

[0032] (3) Primary modification treatment:

[0033] Immerse the wood treated in step (2) into the modified treatment solution A, heat to keep the temperature of the modified treatment solution A at 38°C, take out the wood after ultrasonic vibration ...

Embodiment 2

[0045] A method for prolonging the service life of wood, comprising the steps of:

[0046] (1) Cutting cleaning treatment:

[0047] Cut the wood first, and then wash the cut wood with water for later use;

[0048] (2) Steam explosion treatment:

[0049] Put the wood treated in step (1) into the steam explosion tank for steam explosion treatment. First, put water vapor at a temperature of 105°C into the steam explosion tank, and increase the pressure in the steam explosion tank to 0.40MPa. After heat preservation and pressure holding treatment for 13 minutes, quickly unload the steam explosion tank to normal temperature and pressure, and finally take out the wood and let it cool down to room temperature for later use;

[0050] (3) Primary modification treatment:

[0051] Immerse the wood treated in step (2) into the modified treatment solution A, heat to keep the temperature of the modified treatment solution A at 40°C, take out the wood after ultrasonic vibration treatment ...

Embodiment 3

[0063] A method for prolonging the service life of wood, comprising the steps of:

[0064] (1) Cutting cleaning treatment:

[0065] Cut the wood first, and then wash the cut wood with water for later use;

[0066] (2) Steam explosion treatment:

[0067] Put the wood treated in step (1) into the steam explosion tank for steam explosion treatment. Firstly, water vapor with a temperature of 106°C is introduced into the steam explosion tank, and the pressure in the steam explosion tank is increased to 0.42MPa. After heat preservation and pressure holding treatment for 14 minutes, quickly unload the steam explosion tank to normal temperature and pressure, and finally take out the wood and let it cool down to room temperature for later use;

[0068] (3) Primary modification treatment:

[0069] Immerse the wood treated in step (2) into the modified treatment solution A, heat to keep the temperature of the modified treatment solution A at 42°C, take out the wood after ultrasonic vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com