Modular design glass-ceramic heat treatment production line

A modular design and glass-ceramic technology, applied in the field of annealing and crystallization heating furnaces for glass-ceramics, can solve the problems of inability to realize rapid assembly and assembly of heat treatment production lines, and unrealized modular design of heat treatment production lines, etc., to achieve easy cleaning and wide application range Extensive and shortened construction period effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

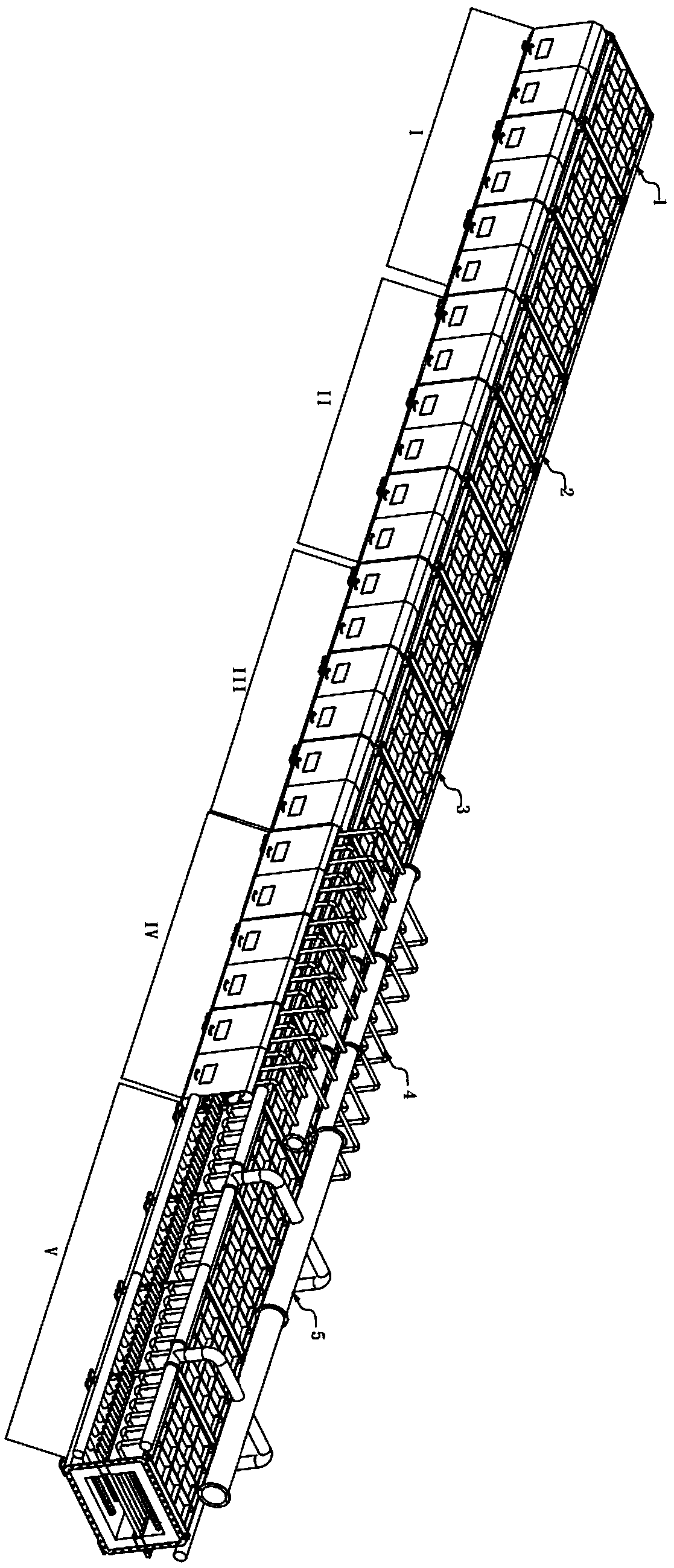

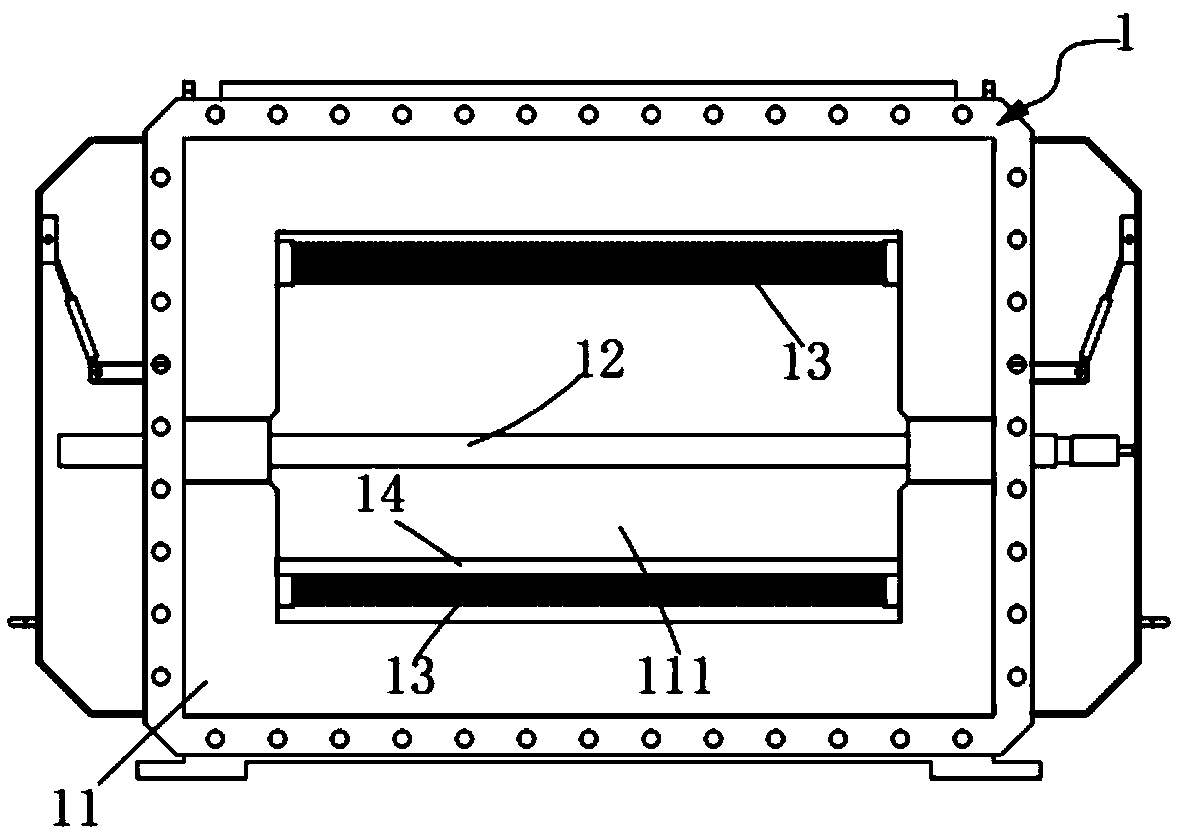

[0078] Such as figure 1 , figure 2 , image 3 , Figure 5 , Figure 8 and Figure 11 As shown, a modular design glass-ceramic heat treatment production line includes:

[0079] A heating zone I, the heating zone I is formed by sealing and splicing assembly of several heating modules 1, along the conveying direction of the heating zone I, the temperature of the glass-ceramics in the heating zone I is gradually increased;

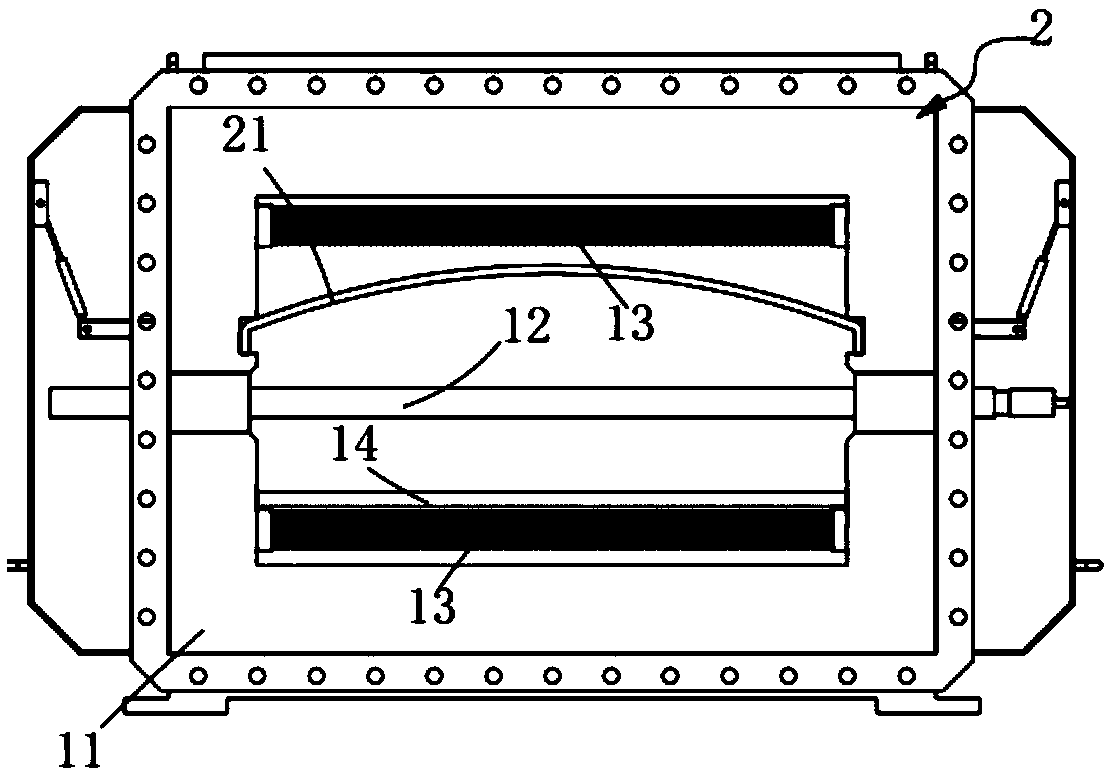

[0080] Crystallization zone II, the crystallization zone II is formed by a number of crystallization modules 2 sealed and spliced together, the input end of the crystallization zone II is connected to the output end of the heating zone I, and the crystallized glass is crystallized The temperature in zone II is constant, and the top of the crystallization module 2 is provided with a temperature equalizing member 21;

[0081] Rapid cooling zone III, the rapid cooling zone III is formed by sealing and splicing and assembling a plurality of the rapid cool...

Embodiment 2

[0104] image 3 It is a structural schematic diagram of Embodiment 2 of a modular design glass-ceramic heat treatment production line of the present invention; as image 3 As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this second embodiment and the first embodiment shown in Figure 1 is that:

[0105] Such as image 3 and Figure 4 As shown, a modular design heat treatment production line for glass-ceramics, the temperature equalizing member 21 is arranged above the first conveying member 12 in the crystallization module 2, and it is arranged along the opening direction of the heating and cooling furnace 3211, And its longitudinal section is arc-shaped, the middle part of the temperature uniform part 21 in the horizontal direction is higher than the two ends, and the t...

Embodiment 3

[0111] Image 6 It is a structural schematic diagram of Embodiment 3 of a modular design glass-ceramic heat treatment production line of the present invention; as Image 6 As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this second embodiment and the first embodiment shown in Figure 1 is that:

[0112] Such as Image 6 and Figure 7 Shown, a kind of modular design glass-ceramic heat treatment production line, described fast cooling component 31 comprises:

[0113] The fast cooling tube 311, the fast cooling tube 311 is arranged across the second furnace 321 of the fast cooling module 3, and its two ends are opened through the two sides of the second furnace 321. The outside of the second furnace body 32, and it is arranged on the vertical direction upper and lower side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com