Biomass fuel forming preparation device

A biomass fuel and preparation device technology, applied in the direction of waste fuel, fuel, solid fuel, etc., can solve problems such as machine jamming, achieve the effects of cost reduction, convenient use, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

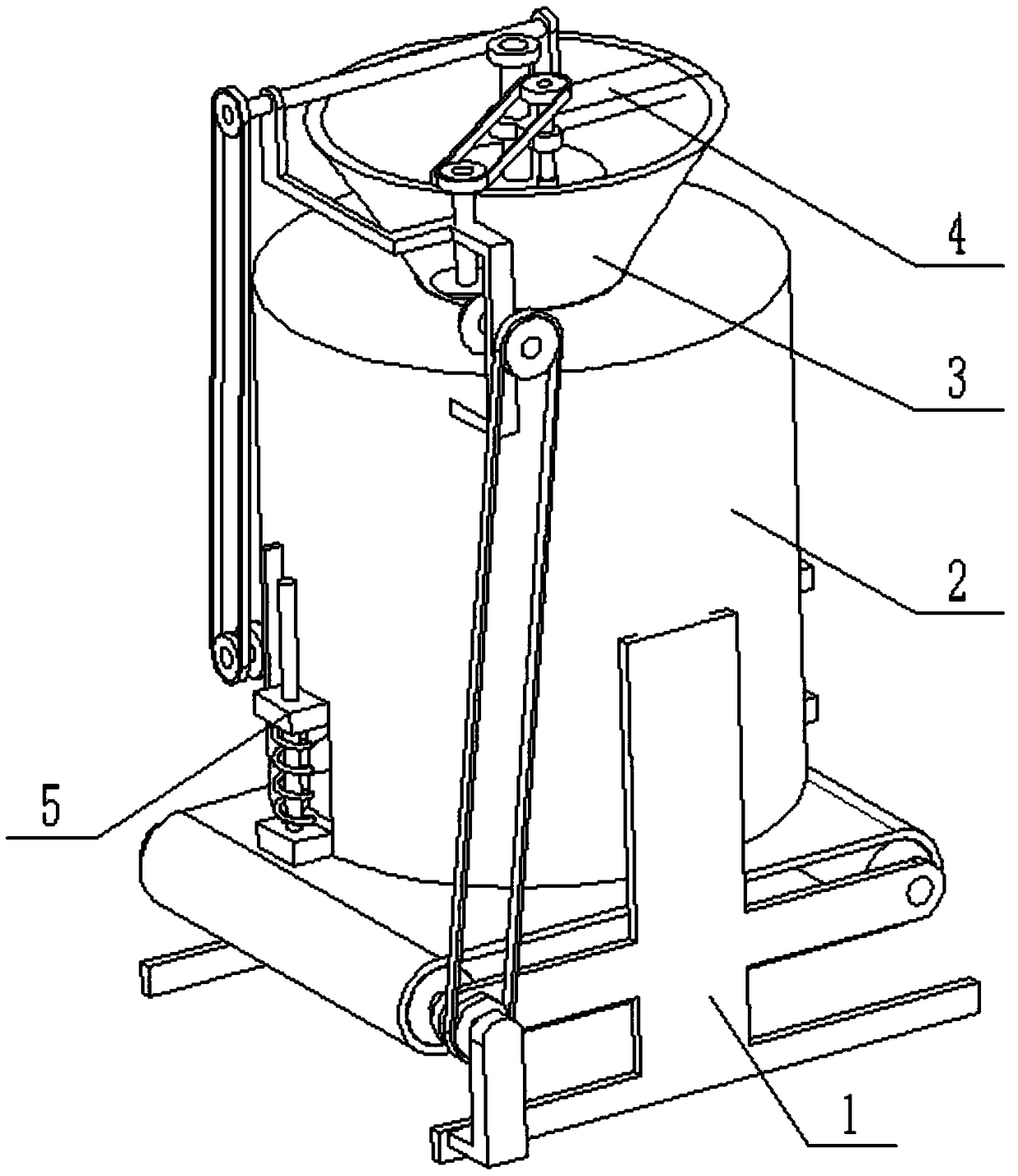

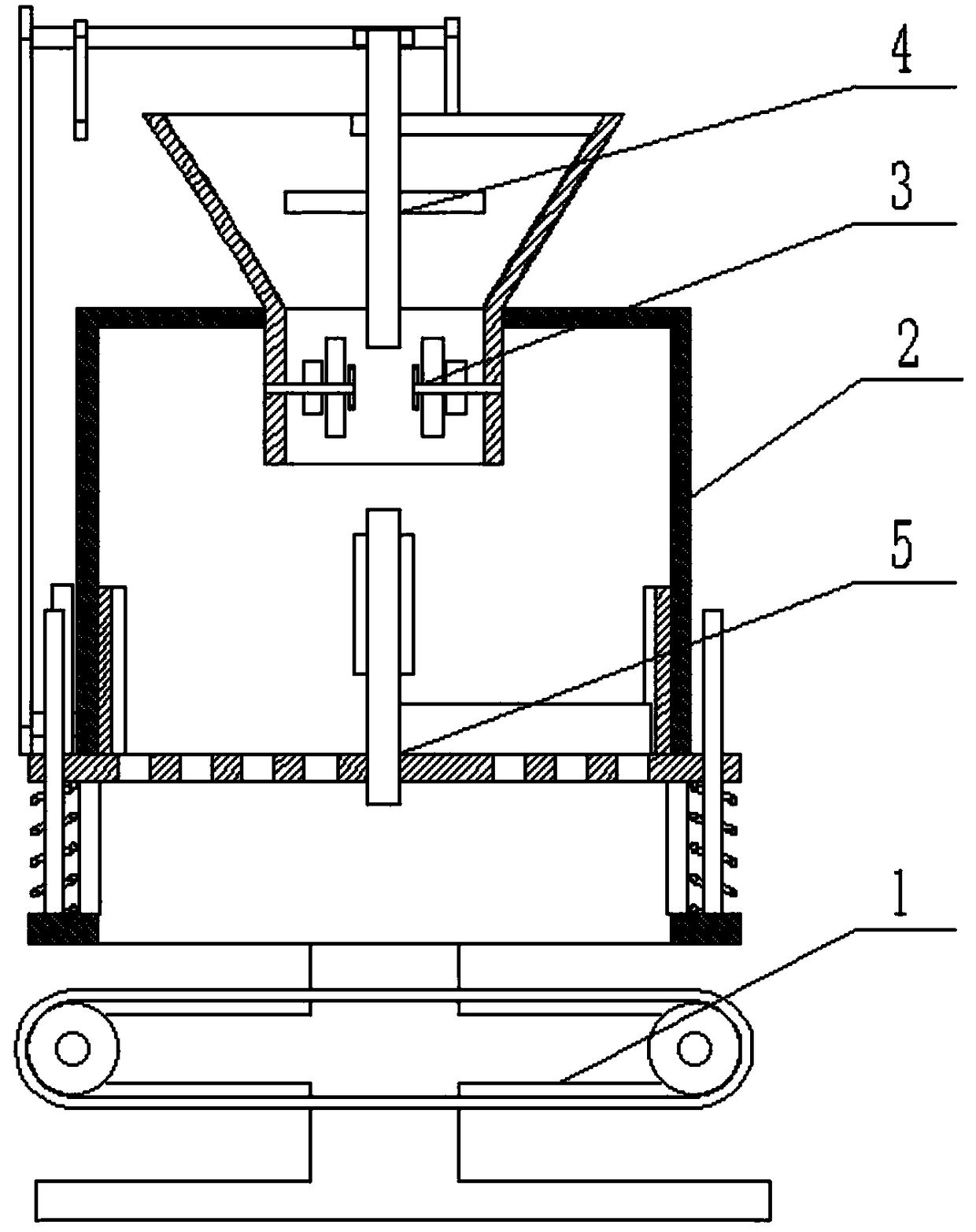

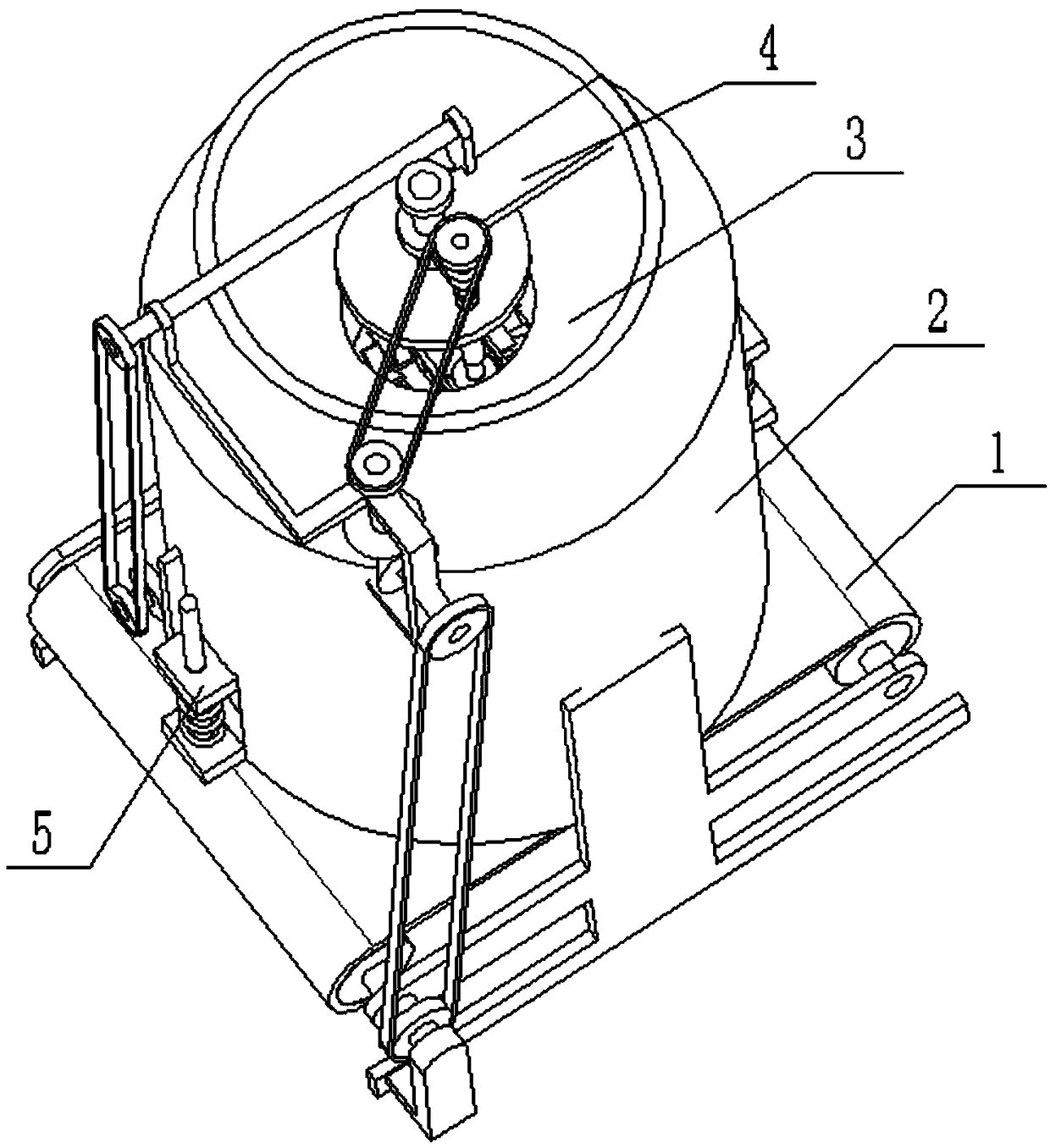

[0028] Combine below Figure 1-10 Describe this embodiment, a biomass fuel molding preparation device, including a conveyor belt support seat 1, a fuel molding cylinder 2, a raw material feeding part 3, an overload prevention adjustment part 4 and a raw material forming plate 5, the conveyor belt support seat assembly 1 includes the first roller shaft 1-1, the second roller shaft 1-2 and the support frame 1-5; the two ends of the first roller shaft 1-1 are respectively rotatably connected to the two support frames 1 through bearings with seats The left end of -5, the two ends of the second roller shaft 1-2 are connected to the right end of the two support frames 1-5 through the belt seat bearing rotation respectively;

[0029]The fuel molding cylinder 2 includes a cylinder body 2-1, a spring seat 2-2, a sleeve rod 2-3, a spring 2-4, a shaft bracket rod 2-5, a rotating shaft 2-6, and a driven pulley 2- 7. Driving bevel gear 2-8, driven bevel gear 2-9, driving shaft 2-10, drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com