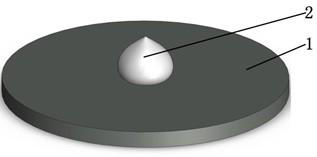

A method to realize gallium-based liquid metal spreading on solid sheet surface

A liquid metal, solid technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of high process cost, labor cost, difficult industrialization promotion, etc., to achieve simple process and improve wettability , the effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

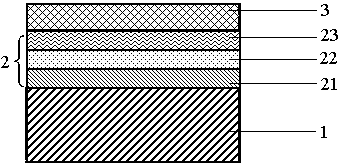

[0024] (1) High-purity Ga 2 o 3 The target is installed in the water-cooled RF cathode target groove in the sputtering chamber of the magnetron sputtering device, the cleaned copper sheet is fixed on the substrate holder, the substrate holder is inserted into the substrate turntable in the sputtering chamber, and adjusted Copper and Ga 2 o 3 The target distance is 60mm.

[0025] (2) Vacuum the sputtering chamber until the base pressure of the sputtering chamber is less than 5.0×10 -4 Pa, fill the sputtering chamber with high-purity Ar gas with a flow rate of 20 SCCM, and adjust the pumping volume to maintain the Ar pressure in the sputtering chamber at 2 Pa.

[0026] (3) Turn on Ga 2 o 3RF power supply for the target, sputtering power density 1.5W / cm 2 , after the radio frequency glow discharge is stable, open the baffle to prepare Ga on the surface of the copper sheet 2 o 3 thin film, by controlling the sputtering time to make Ga 2 o 3 The film thickness is 50nm. ...

Embodiment 2

[0030] (1) High-purity Ga 2 o 3 The target is installed in the water-cooled RF cathode target groove in the sputtering chamber of the magnetron sputtering device, the cleaned silicon wafer is fixed on the substrate holder, the substrate holder is inserted into the substrate turntable in the sputtering chamber, and adjusted Silicon and Ga 2 o 3 The target distance is 70mm.

[0031] (2) Vacuum the sputtering chamber until the base pressure of the sputtering chamber is less than 5.0×10 -4 Pa, fill the sputtering chamber with high-purity Ar gas with a flow rate of 20 SCCM, and adjust the pumping volume to maintain the Ar pressure in the sputtering chamber at 0.2 Pa.

[0032] (3) Turn on Ga 2 o 3 The RF power supply of the target, the sputtering power density is 5.3W / cm 2 , after the radio frequency glow discharge is stable, open the baffle to prepare Ga on the surface of the silicon wafer 2 o 3 thin film, by controlling the sputtering time to make Ga 2 o 3 The film thic...

Embodiment 3

[0036] (1) High-purity Ga 2 o 3 The target is installed in the water-cooled RF cathode target groove in the sputtering chamber of the magnetron sputtering device, the cleaned copper sheet is fixed on the substrate holder, the substrate holder is inserted into the substrate turntable in the sputtering chamber, and adjusted Copper and Ga 2 o 3 The target distance is 65mm.

[0037] (2) Vacuum the sputtering chamber until the base pressure of the sputtering chamber is less than 5.0×10 -4 Pa, fill the sputtering chamber with high-purity Ar gas with a flow rate of 20 SCCM, and adjust the pumping volume to maintain the Ar pressure in the sputtering chamber at 0.5 Pa.

[0038] (3) Turn on Ga 2 o 3 RF power supply for the target, sputtering power density 2.5W / cm 2 , after the radio frequency glow discharge is stable, open the baffle to prepare Ga on the surface of the copper sheet 2 o 3 thin film, by controlling the sputtering time to make Ga 2 o 3 The film thickness is 100n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com