Array-jet large-size isometric aluminum alloy ingot additive manufacturing device and method

An aluminum alloy ingot and additive manufacturing technology, applied in the field of metallurgy, can solve the problems of impossible large-scale ingot production, low efficiency of metal droplet forming, and low preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

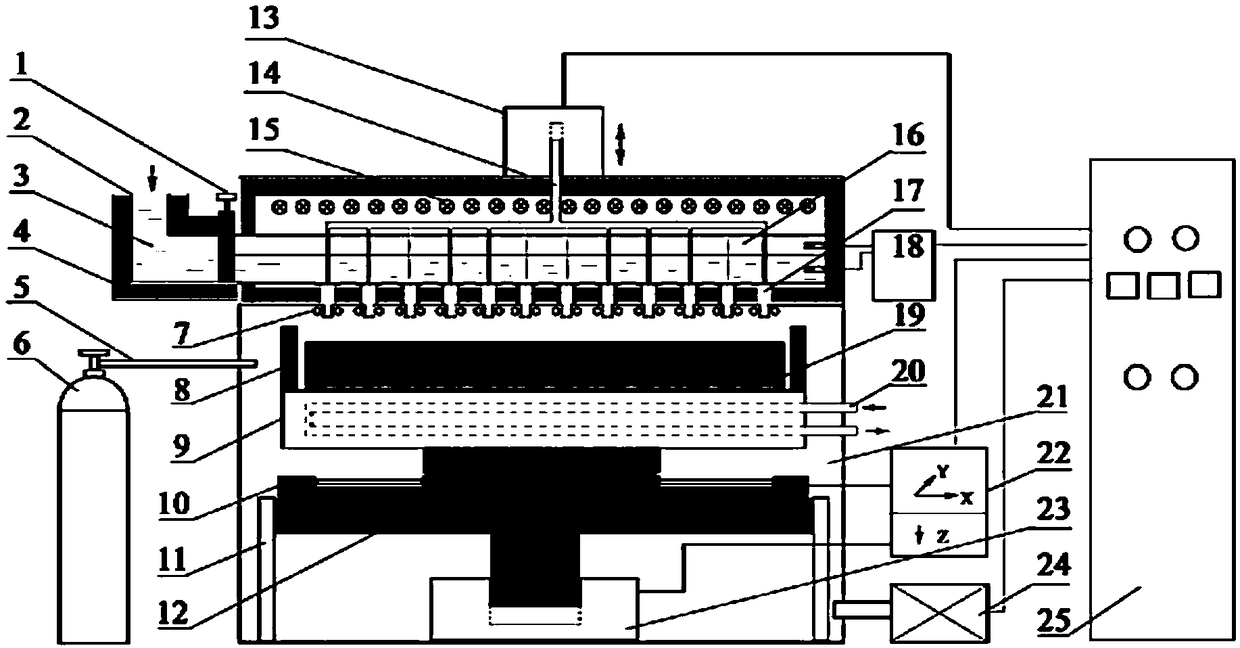

[0033] Such as figure 1 As shown, it is the array injection type large-size fully equiaxed crystal aluminum alloy ingot additive manufacturing device involved in this embodiment, including: inlet gate 1, diversion groove 2, aluminum liquid 3, insulation layer 4, air intake pipe 5, inert Gas 6, nozzle heater 7, baffle plate 8, condensation table 9, two-dimensional motion device 10, guide rail 11, support table 12, upper guide device 13, stopper rod 14, cavity heater 15, aluminum liquid chamber 16, nozzle 17. Liquid level gauge 18, casting ingot 19, cooling water pipe 20, airtight condensation chamber 21, motion control unit 22, down-leading device 23, vacuum pump 24, and master control unit 25.

[0034] The aluminum liquid chamber maintains 1 atmosphere, and the airtight condensation chamber is completely sealed. The pressure P can be adjusted by the vacuum pump 24 and the intake pipe. During the ingot preparation process, the pressure P is less than 1 atmosphere.

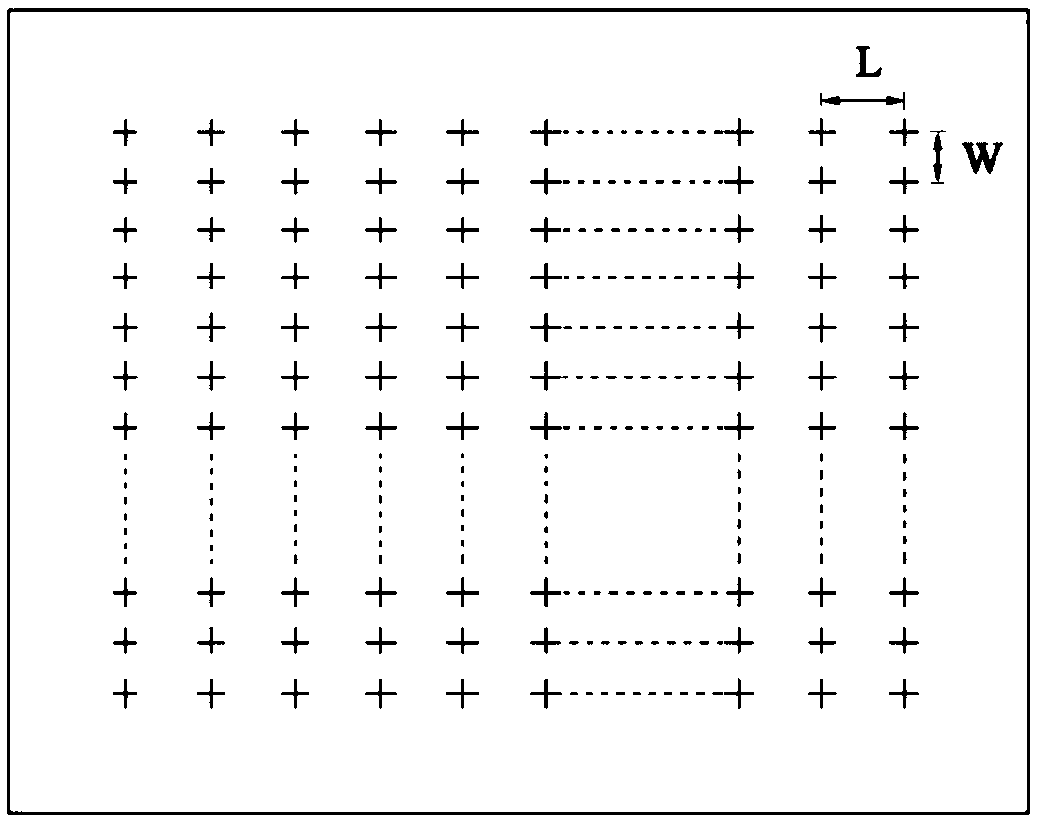

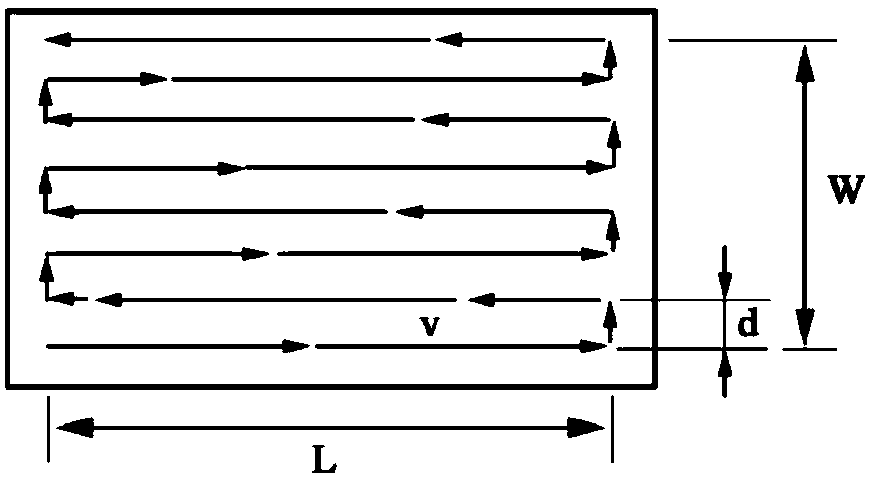

[0035] Suc...

Embodiment 2

[0044] In this example, the Al-4.5Cu aluminum alloy ingot is prepared by the same method as in Example 1. The temperature of the molten aluminum is set at 700°C, the diameter of the nozzle is 6mm, the horizontal moving speed of the cooling table is 260mm / s, and the spraying area of the array nozzle is The thickness of the ingot is 2m*5m, and the thickness of the ingot is 0.8m. After 60 minutes, a large ingot of 2m*5m*0.8m is prepared. The structure of the ingot is dense, without macro-segregation, and it is fully equiaxed, with an average grain size of 60-90 μm. The metallographic photos of the 1 / 4 and 1 / 2 positions along the centerline of the ingot cross section are as follows: Figure 6 , Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com