An untwisting twister, an ultrafine yarn spinning machine, and an ultrafine yarn spinning method

A twister and untwisting technology, which is applied to spinning machines, textiles, papermaking, and drafting equipment, can solve problems such as deterioration of yarn uniformity, fiber damage in yarns, yarn dryness, and weakening, etc., to achieve Simple and reliable action, low production cost, good application market effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

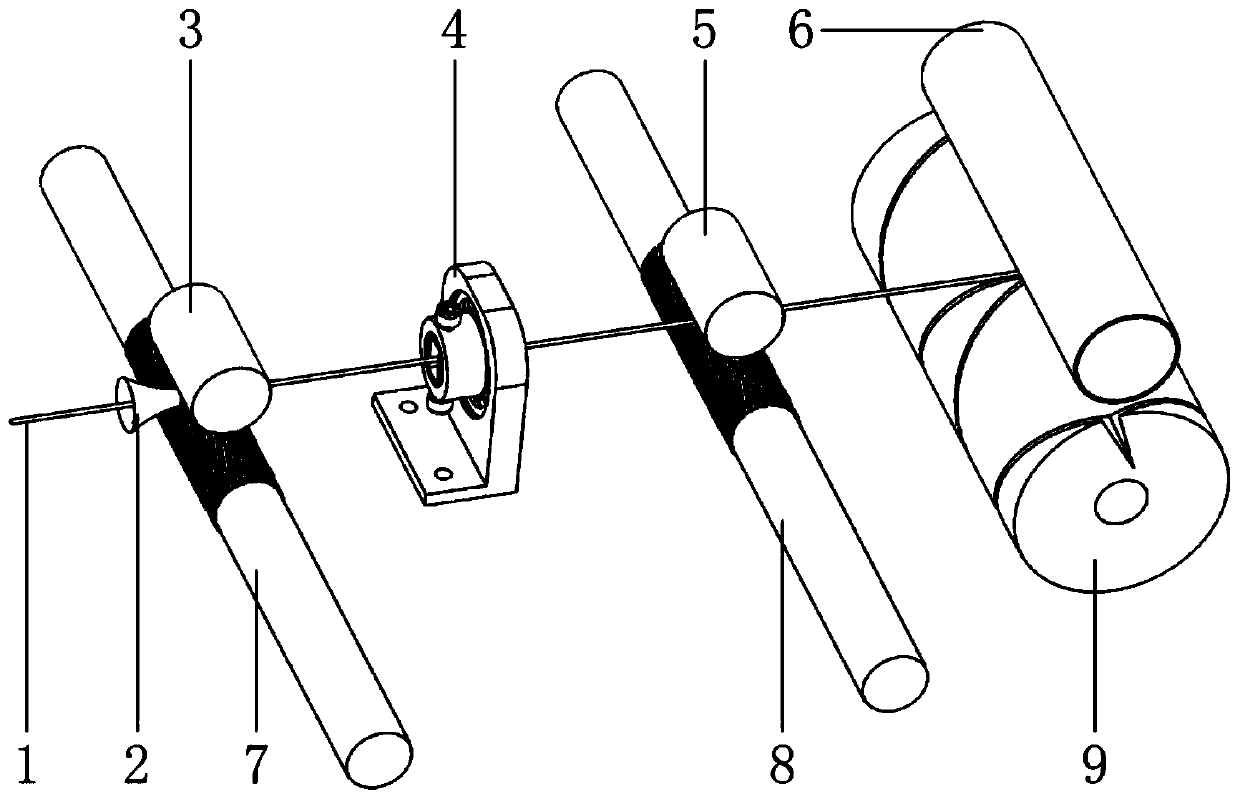

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

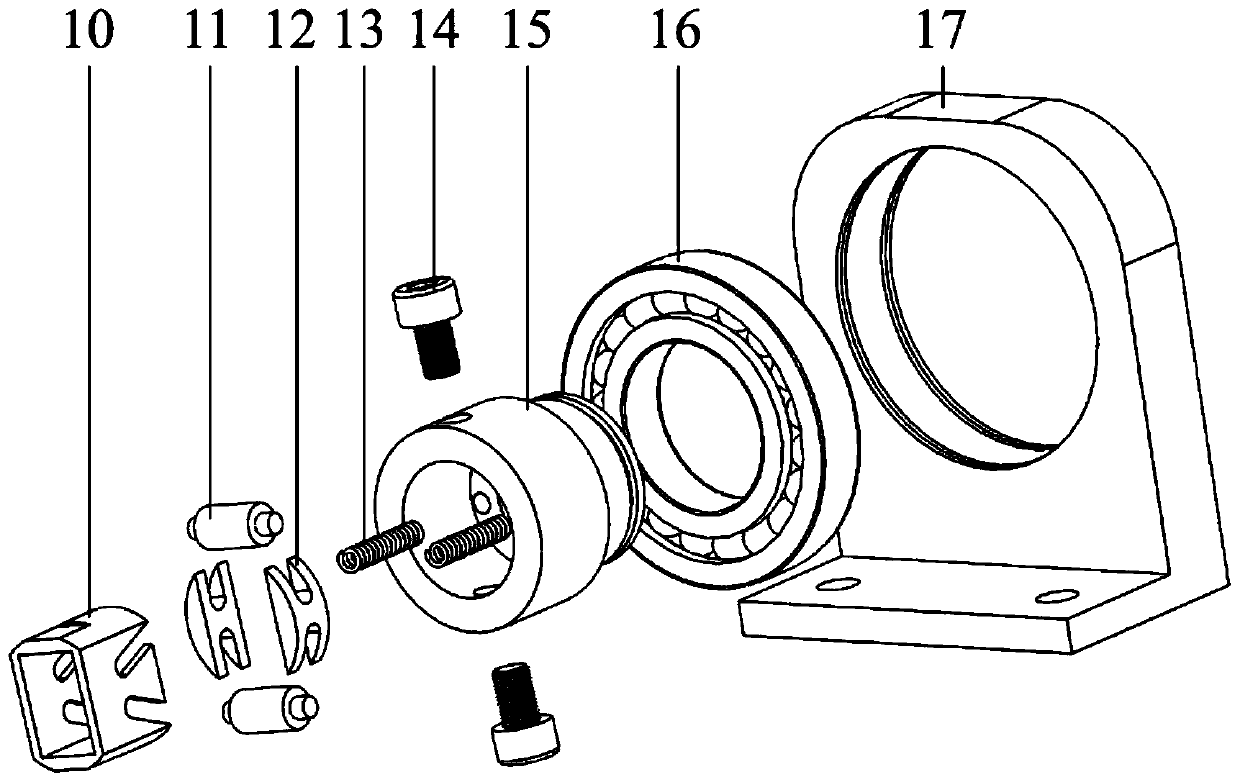

[0037] as attached figure 2 As shown, the untwisting twister 4 provided by the embodiment of the present invention consists of an M-shaped coin seat 10, a clamping rubber roller 11, an H-shaped rubber roller deck 12, a deck spring 13, a coin seat positioning bolt 14, and a coin seat Sleeve 15, sleeve bearing 16 and L-shaped base 17 form. A sleeve bearing 16 is installed in the hole 17 of the L-shaped base, and the two sides of the outer circle of the bearing are fixed by snap springs. One end of the copper coin holder sleeve 15 passes through the sleeve bearing 16 for transmission, and is fixed with a snap ring matching the sleeve steps. , the other end is equipped with an M-shaped copper coin holder 10, a clamping rubber roller 11, an H-shaped rubber roller holder 12 and a holder spring 13; a pair of parallel clamping rubber rollers 11 are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com