A kind of prefabricated part grain workshop and its preparation method and use method

A prefabricated and horizontal technology, applied in the field of prefabricated grain workshops, can solve the problems that the grain workshops cannot meet the stability and low investment at the same time, and achieve the effects of easy construction quality assurance, simple construction operation, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

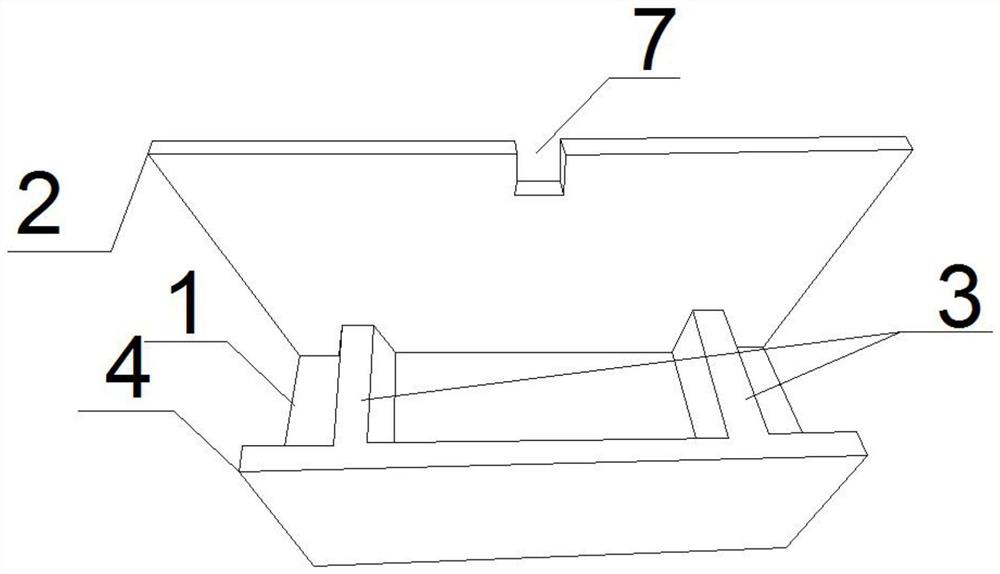

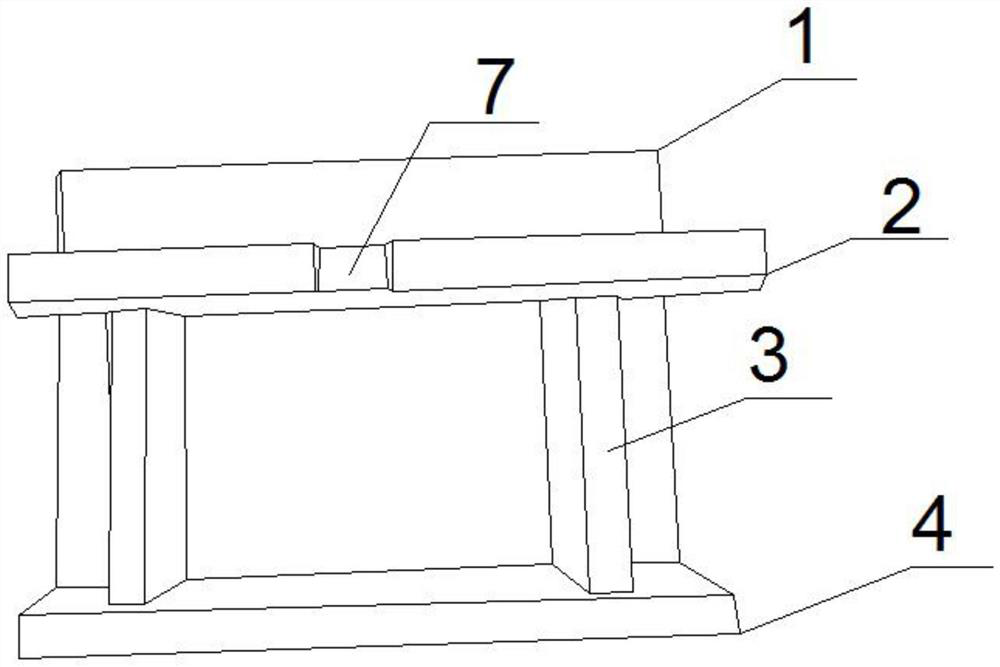

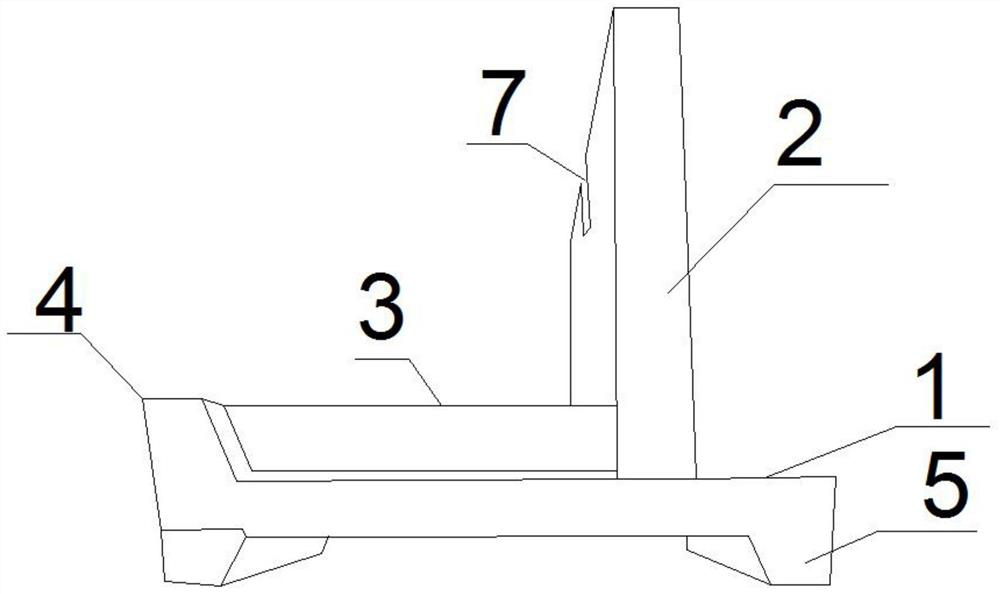

[0019] Specific embodiment 1: A prefabricated part grain workshop of this embodiment, which includes a horizontal prefabricated part 1, a retaining wall 3 and a vertical prefabricated part 2, and the lower end surface of the vertical prefabricated part 2 is fixed to the upper end surface of the horizontal prefabricated part 1. Connected; there is an overflow port 7 at the top of the vertical prefabricated part 2; the left end of the horizontal prefabricated part 1 extends outwards to form a terrace body 1 4, and the right end faces downwards to form a terrace body 2 5; the vertical prefabricated part 2 is arranged obliquely , and the inclination direction of the vertical prefabricated part 2 faces the platform body 1 4;

[0020] Two retaining walls 3 are arranged side by side on the upper end surface of the horizontal prefabricated part 1, and one end of the two retaining walls 3 is respectively affixed to the side of the vertical prefabricated part 2, and the other end is affi...

specific Embodiment approach 2

[0022] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the vertical prefabricated part 2 is a cuboid structure. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment is different from Embodiment 1 in that: the overflow port 7 is arranged in the middle of the vertical prefabricated part 2 . Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com