Prefabricated energy dissipation and damping beam-column joint for prestressed concrete frame

A prefabricated beam and concrete technology, applied in earthquake resistance, building types, buildings, etc., can solve the problems of concrete damage at the beam-column interface, insufficient energy dissipation capacity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

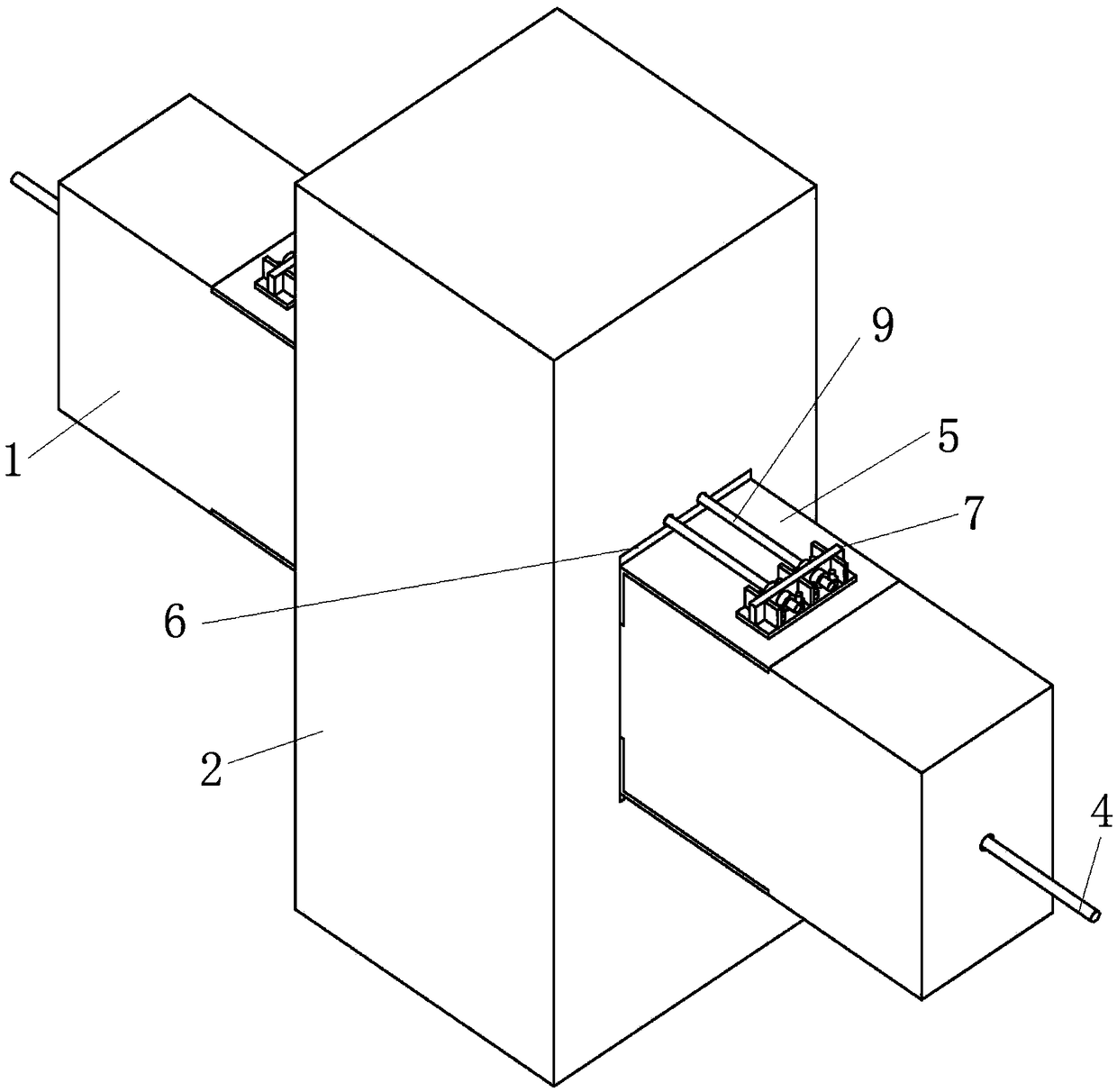

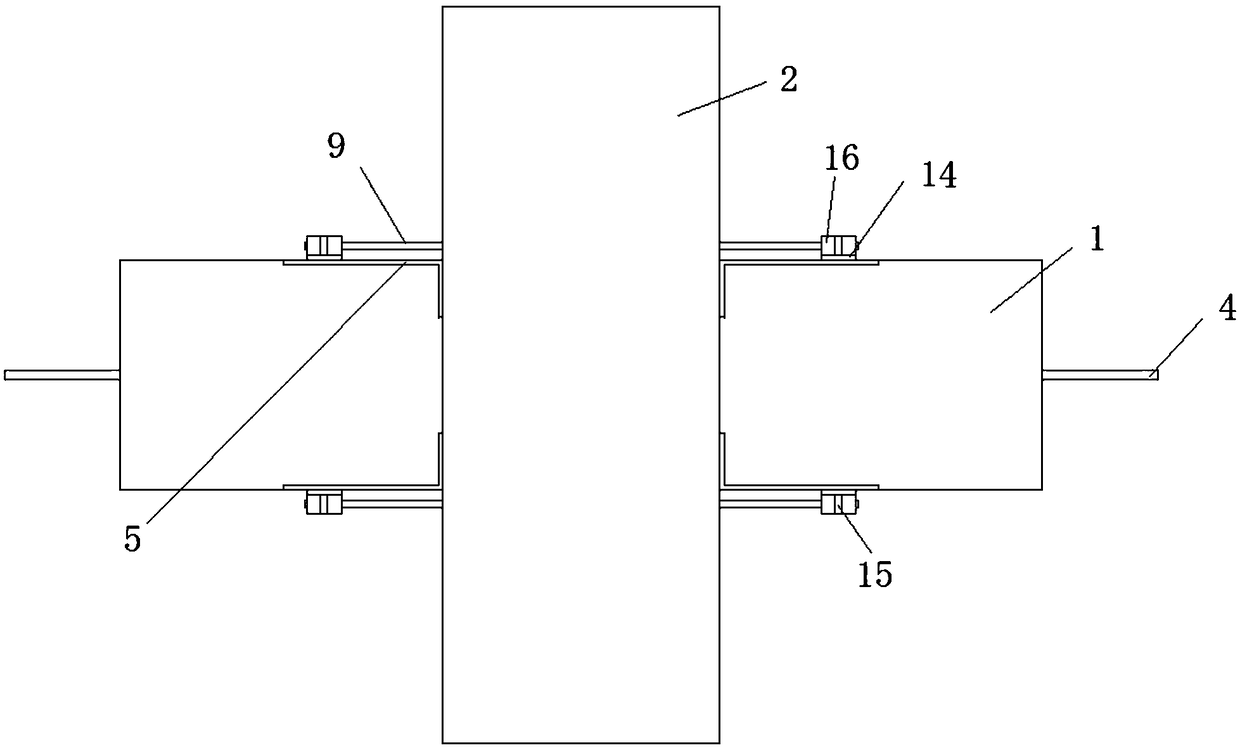

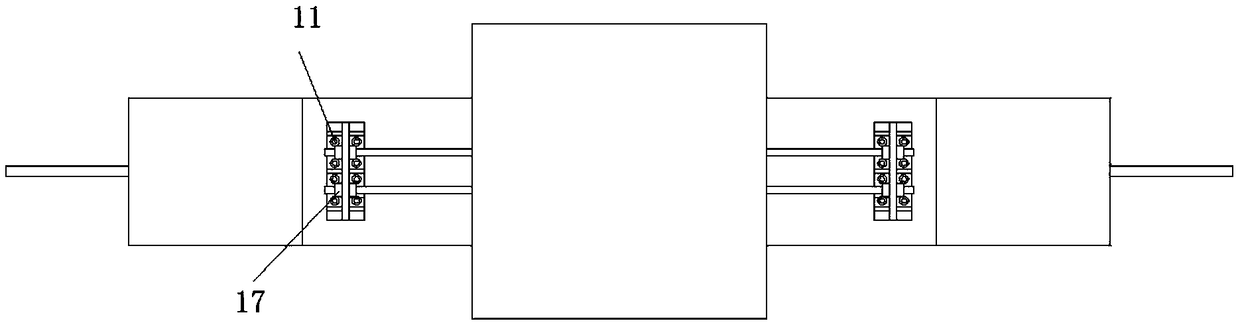

[0045] Such as Figure 1-Figure 6 As shown, a prefabricated prestressed concrete frame energy-dissipating and shock-absorbing beam-column joint, including:

[0046] Along the axis of the prefabricated beam 1, the prestressed steel strand reserved channel 3 of the interconnected prefabricated beam 1 and prefabricated column 2 is provided. The steel strand 4 is connected by grouting between the prestressed steel strand 4 located in the middle of the prefabricated beam 1 and the prestressed steel strand reserved tunnel 3;

[0047] Angle steels 5 are pre-embedded at the upper and lower corners of both ends of the prefabricated beam 1, and reinforced steel plates 6 corresponding to the angle steels 5 are pre-embedded on the prefabricated column 2;

[0048] The angle steel support plate of the angle steel 5 perpendicular to the prefabricated column 2 is provided with an energy-dissipating steel bar joint 7, and the prefabricated column 2 is provided with two penetrating prefabricat...

Embodiment 2

[0062] Such as Figure 7 As shown, a prefabricated prestressed concrete frame energy-dissipating and shock-absorbing beam-column node differs from Embodiment 1 in that the interconnected prefabricated beam 1 and prefabricated column 2 include a prefabricated column 2 and a prefabricated beam 1, so The fixing device is a fixed steel plate 20 embedded in the prefabricated column 2 corresponding to the reinforced steel plate 6, and the energy-dissipating steel rod 9 passes through the fixed steel plate 20 and connects to the fixed steel plate through a fixed bolt 21. 20 connections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com