Wooden clamp for reinforcing reinforced concrete beam lateral formwork and using method thereof

A technology of reinforced concrete beams and wooden clips, which is applied to the connection parts of formwork/formwork/work frame, formwork/formwork/work frame, and on-site preparation of building components, etc., can solve the inconvenience and operation of reinforcing beam side formwork. Complicated and cumbersome, inadequate reinforcement and other problems, to achieve the effect of saving manpower, easy to use, and convenient to make

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

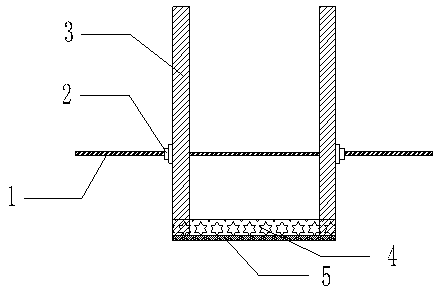

[0030] The wooden clip for strengthening the side form of a reinforced concrete beam of the present invention comprises a U-shaped wooden frame and a screw rod. see now figure 1 , figure 1 It is a structural schematic diagram of a wooden clip according to an embodiment of the present invention. As shown in the figure, the U-shaped wooden frame is provided with a bottom wooden square (not shown in the figure), and the two ends of the bottom wooden square are provided with upright wooden squares 3 perpendicular to the bottom wooden square. The bottom wooden square is 50 mm thick and 100 mm wide. The upright wooden square is 50mm thick and 100mm wide. The height of the upright timber is set according to the height of the reinforced concrete beam, and may be greater than or equal to the height of the reinforced concrete beam.

[0031] The screw 1 is a threaded screw with a diameter of 12mm; the screw passes through the two upright wooden squares of the U-shaped wooden frame, so...

Embodiment 2

[0033] A method for using wooden clips for reinforcing reinforced concrete beam side forms, comprising the following steps:

[0034] a. According to the drawing size of reinforced concrete beams, use 15mm thick multi-layer boards and 50×100mm wooden squares to process and manufacture wooden clips to strengthen the side forms of reinforced concrete beams. The width of wooden clips is equal to the distance between two upright wooden squares equal to the beam width + The thickness of the formwork on both sides of the beam + the width of the upright wooden square on both sides of the beam, set a through hole at a distance of 250mm from the bottom of the wooden clamp, so that the through wire φ12mm screw rod is threaded in a horizontal state, and nuts are provided at both ends of the screw rod. The height of the upright wooden square of the wooden clip is equal to the height of the reinforced concrete beam on site.

[0035] b. After the reinforced concrete beam bottom formwork and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com