A two-drive cutting device based on hydraulic energy recovery

A technology of cutting device and hydraulic energy, which is applied to parts of pumping devices for elastic fluids, pump devices, pumps for special fluids, etc., and can solve problems such as entanglement of debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

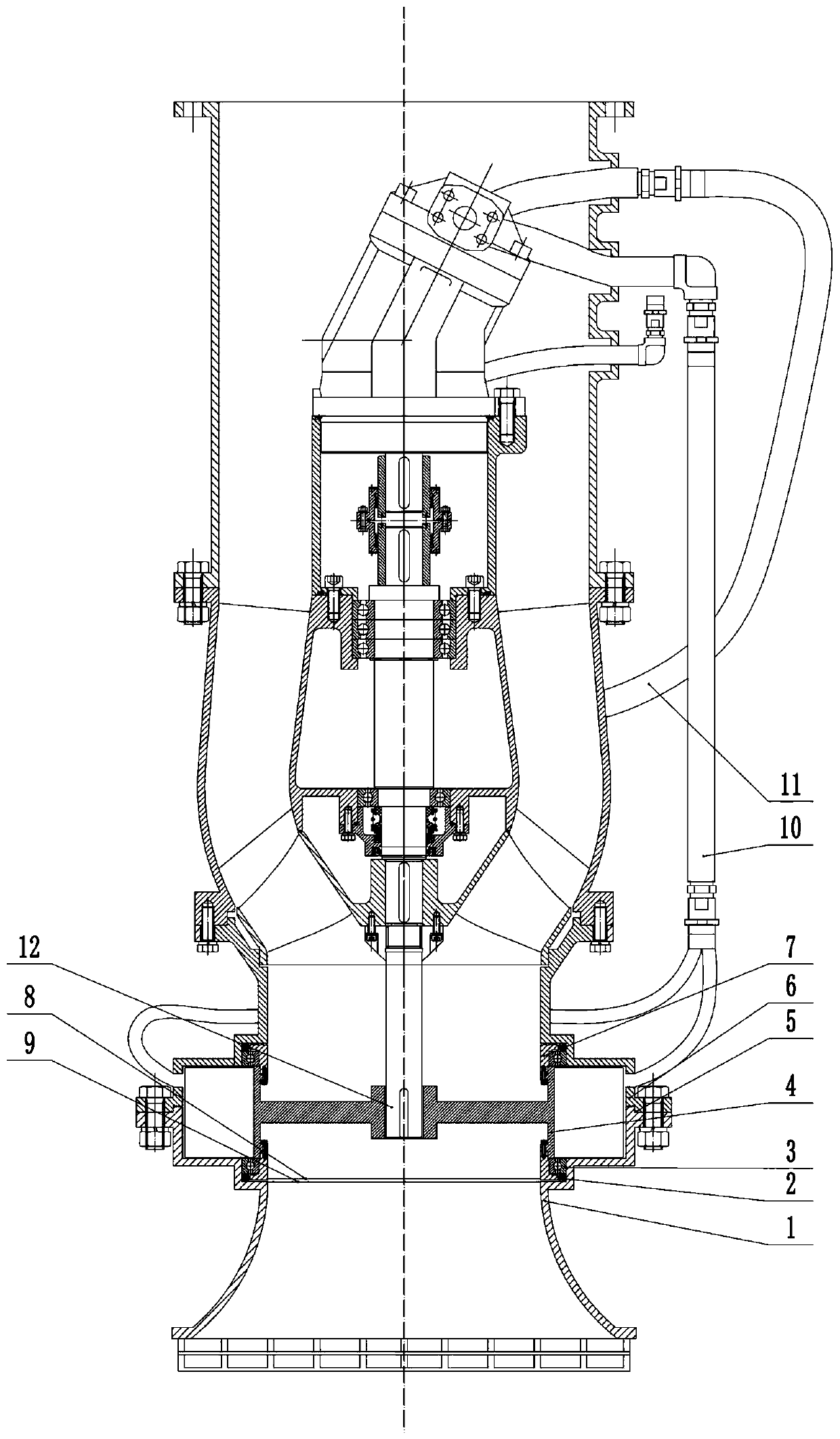

[0030] The invention provides "a two-drive cutting device based on hydraulic energy recovery". It uses the residual energy of the hydraulic oil when the hydraulic system returns oil to drive the rotor to rotate and cut, effectively realizes hydraulic oil cooling and energy recovery, and uses the rotary cutting device to solve the problem of debris winding, while the pump shaft drive mode is different under different requirements. effective supplement.

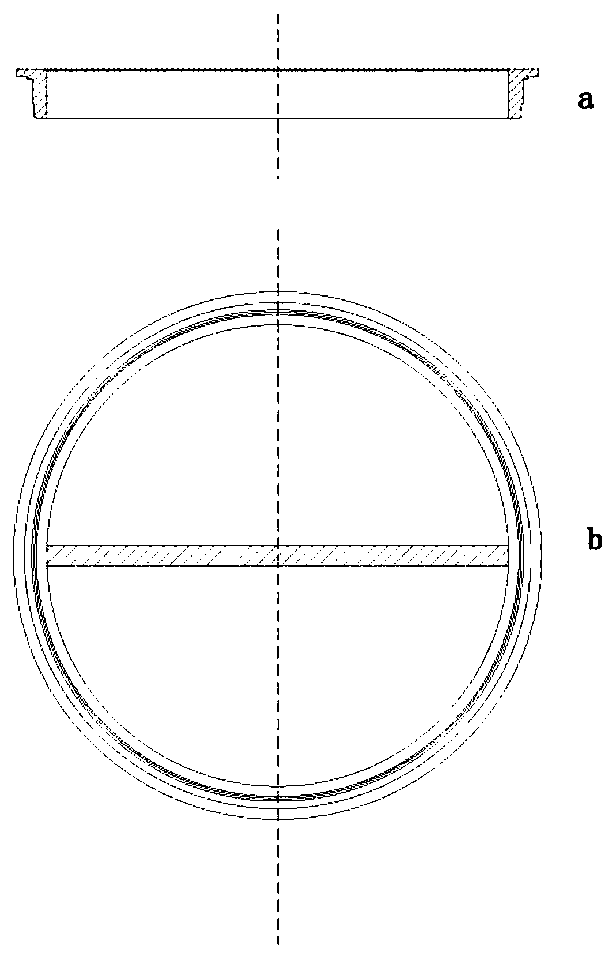

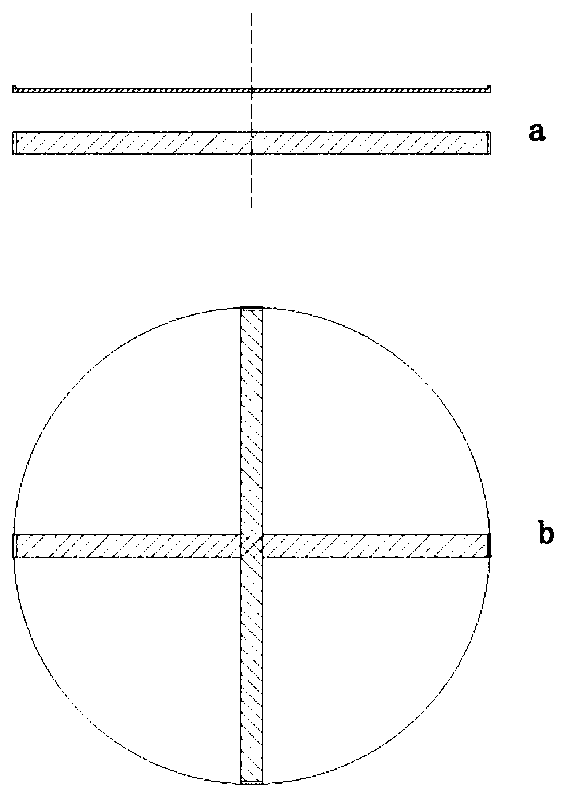

[0031] A two-drive cutting device based on hydraulic energy recovery, the device is installed in the middle of the water inlet and the impeller, including water inlet trumpet 1, skeleton oil seal 2, deep groove ball bearing 3, rotor impeller 4, rubber sealing ring 5, Oil chamber upper cover 6, bearing cover 7, moving knife head 8, static knife holder 9, oil inlet pipe 10 and oil outlet pipe 11; water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com