Stir frying fume collecting haze removing machine

A technology for smoke removal and stir fry, which is applied in the field of stir fry smoke collection and haze removal machines, can solve the problems of difficult adaptation of the flammability of plant fibers, and achieves the effects of compact structure, good energy saving effect and good purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

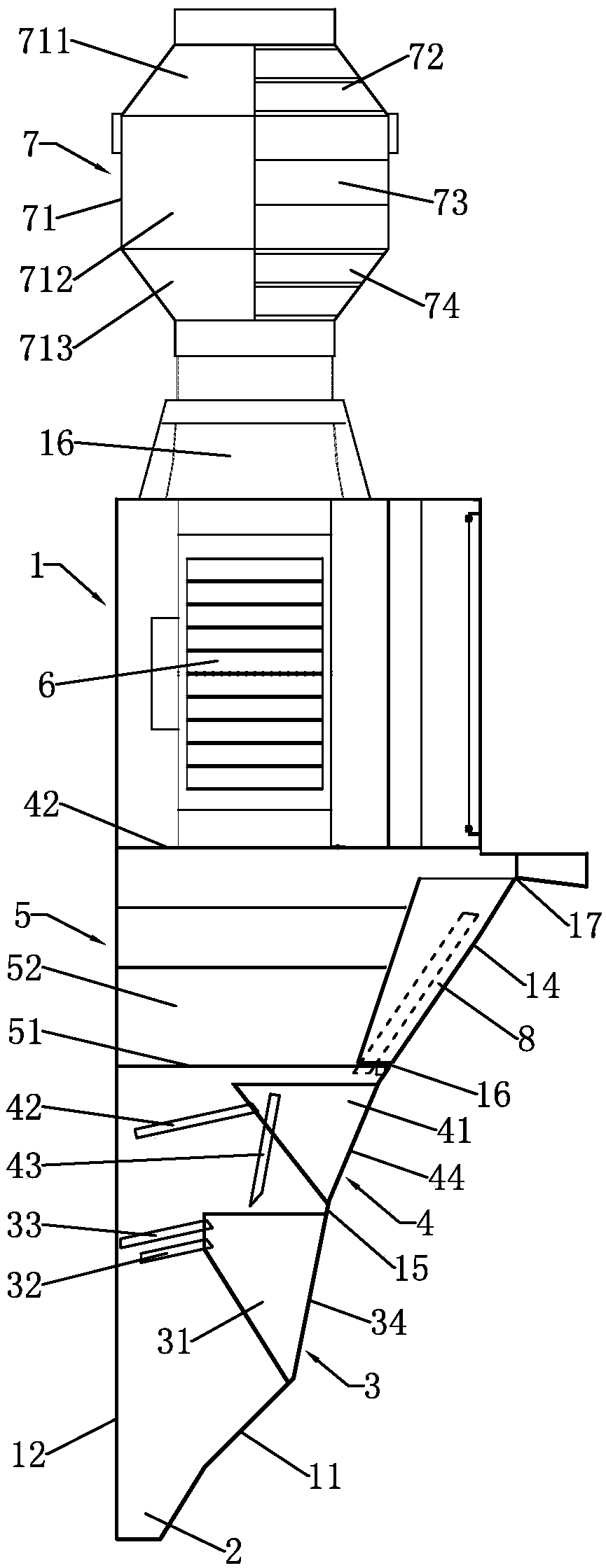

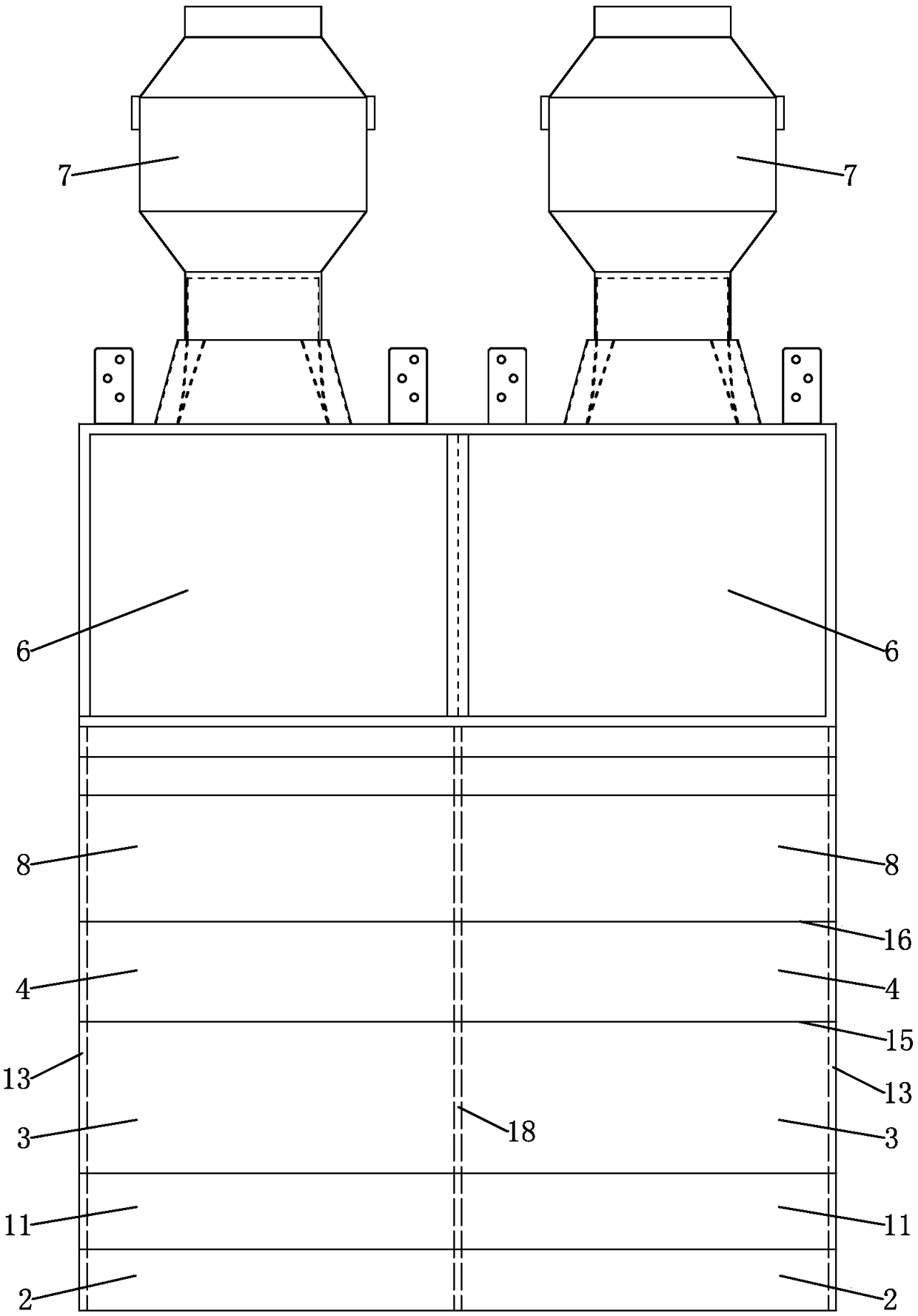

[0017] Below in conjunction with accompanying drawing, invention is described in further detail.

[0018] figure 1 with figure 2 Schematically shows a stir-frying smoke collection and haze removal machine according to an embodiment of the present invention.

[0019] refer to figure 1 with figure 2 The stir-frying smoke collection and haze removal machine includes a casing 1 and an oil collecting tank 2, a first cooling water tank 3, a second cooling water tank 4, a negative pressure plant fiber purification device 5, and a positive pressure purification and noise reduction fan 6. device 7 and the third cooling water tank 8.

[0020] The lower part of the casing 1 is provided with a main air inlet 11 , and the oil collecting tank 2 is arranged at the bottom of the casing 1 and connected to the lower side of the main air inlet 11 . The first cooling water tank 3 is arranged on the top of the main air inlet 11, the second cooling water tank 4 is arranged on the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com