Open-pit mine production dispatching commanding method based on drone

A production scheduling and unmanned aerial vehicle technology, applied in photo interpretation, camera devices, etc., can solve problems such as low efficiency, information loss, lag in production data update, etc., and achieve efficient image analysis and processing, large aerial photography range, and accurate visualization. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The development of high-precision UAV aerial photography surveying and mapping technology provides a safe and efficient solution for the collection of open-pit mining data; the three-dimensional analysis of aerial images and its specialized data post-processing technology can provide digital line map and digital Surveying and mapping results such as surface models provide basic data for 3D modeling and production planning and design of open-pit mines, real-world inspections of open-pit mines and comparison and analysis of execution deviations, and provide technical support for the research and issuance, inspection and deviation correction of open-pit mine scheduling instructions, and It has the advantages of accurate and comprehensive data and good visibility of results, and can also carry out remote diagnosis and guidance by open-pit mine management experts.

[0034] This embodiment provides a UAV-based open-pit mine production scheduling command method, the method incl...

Embodiment 2

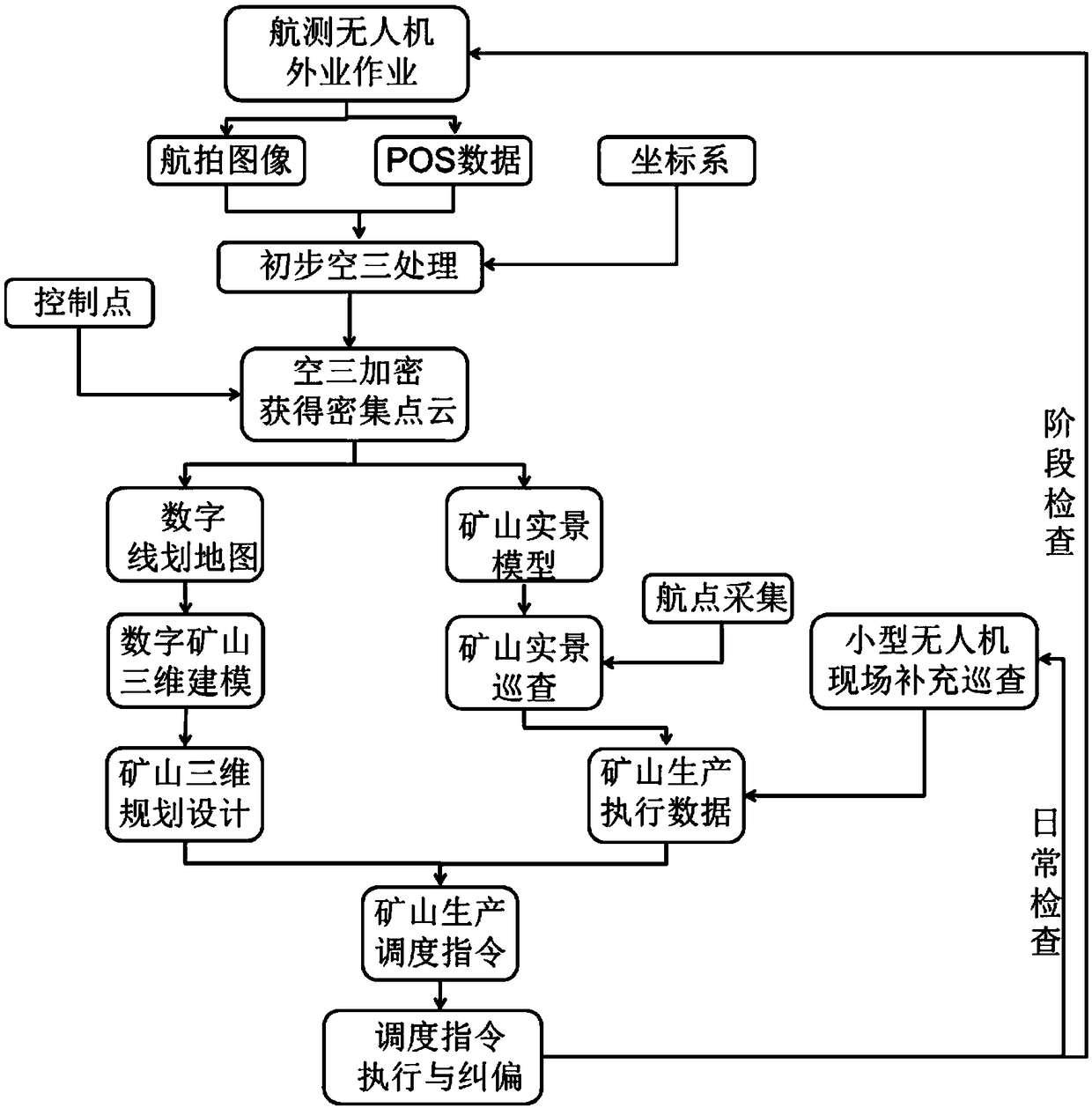

[0050] Such as figure 1 As shown, the UAV-based open-pit mine production scheduling command method of this embodiment specifically includes the following steps:

[0051] 1) Field operations of light fixed-wing aerial survey drones, including aircraft assembly, ground station placement, camera installation and commissioning, ground station software inspection and setting, flight inspection, flight plan planning and design, and flight plan drawing. Finally, upload the flight plan and execute flight mission.

[0052] 2) Collect the orthophoto and POS data obtained by the aerial work of the light fixed-wing aerial survey UAV, and then perform data preprocessing; among them, the data preprocessing includes the difference of the POS data and the matching of the image and the POS data, so that the data The format meets the format requirements of the image analysis software;

[0053] 3) Preliminary aerial triangulation (aerial triangulation) processing: use the collected aerial imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com