Intelligent numerically-controlled workshop design verification system

A technology for design verification and numerical control equipment, applied in general control systems, control/adjustment systems, program control, etc., can solve problems affecting production efficiency, delays, etc., and achieve the effect of improving sampling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

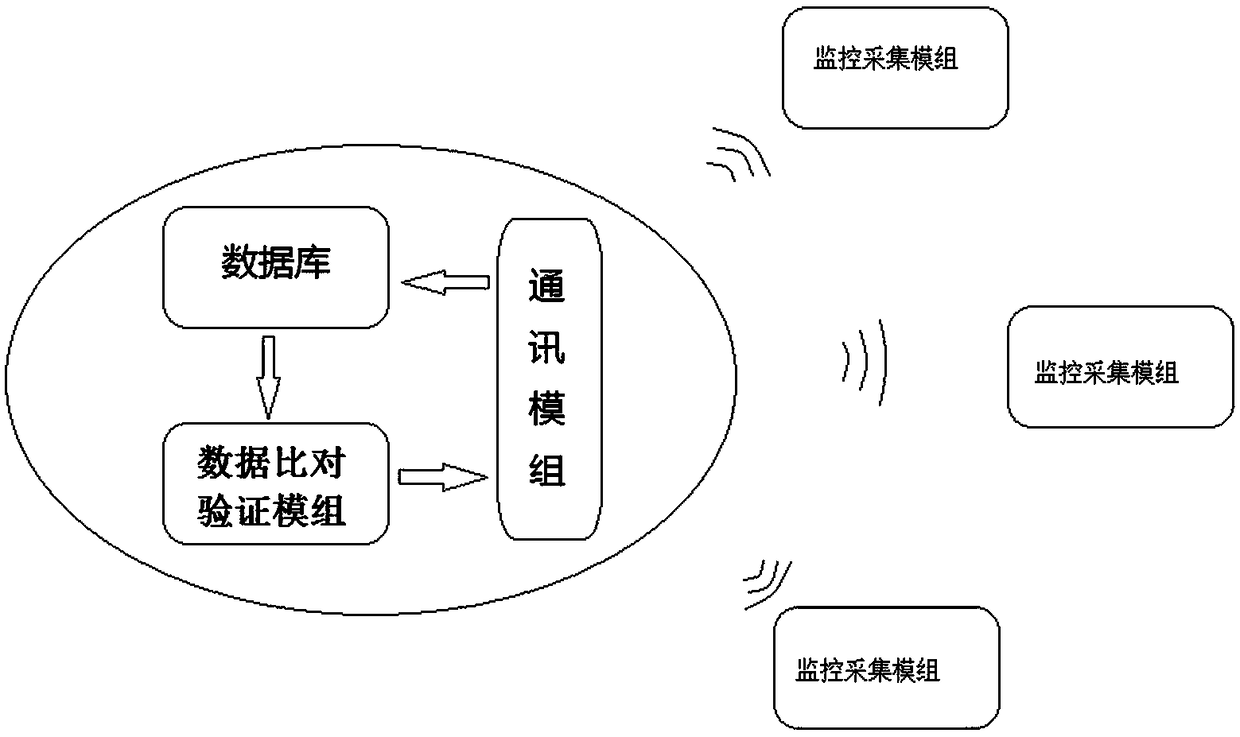

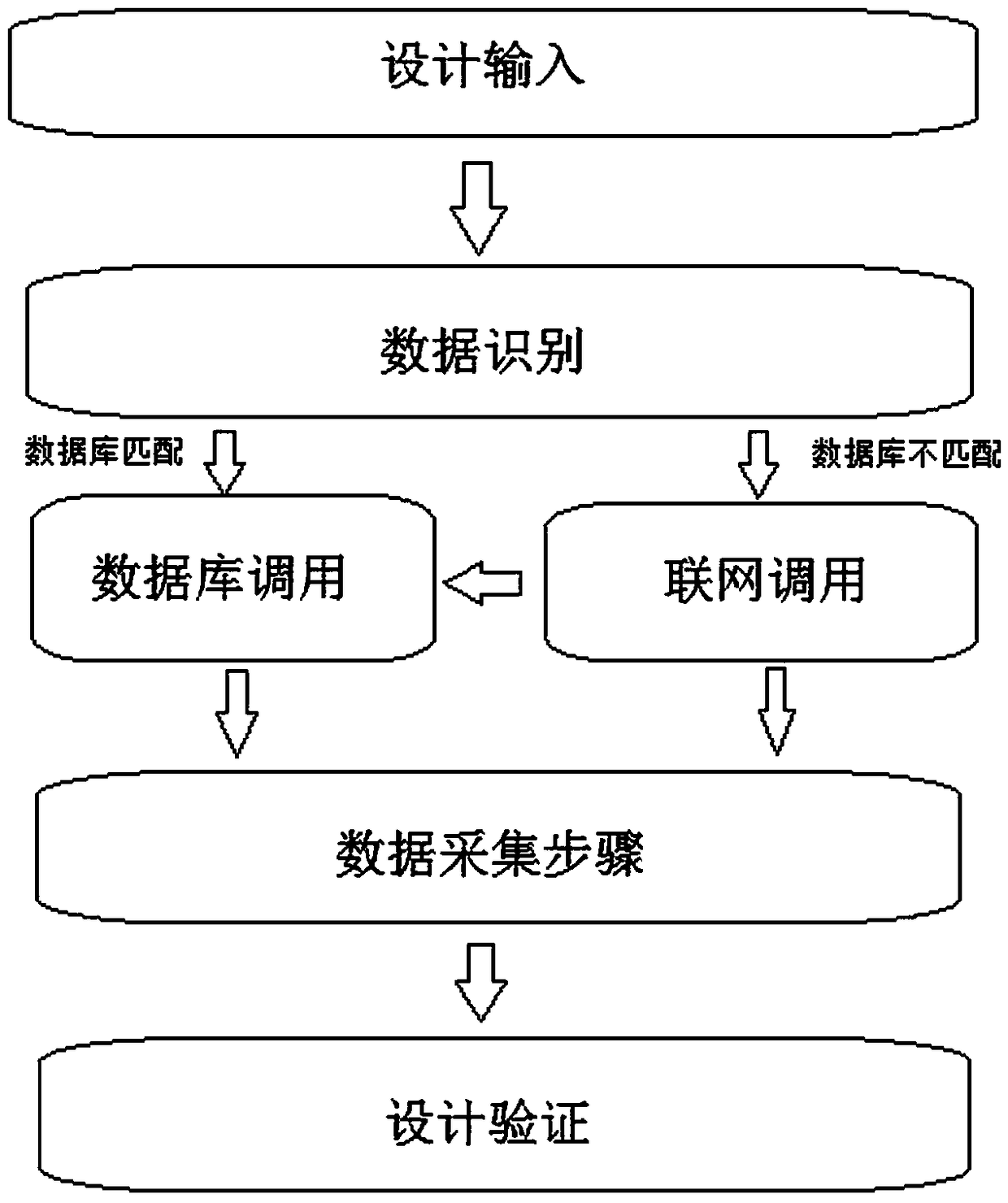

[0035] As a most basic embodiment of the present invention, such as figure 1, discloses an intelligent numerical control workshop design verification system, including a processing center with a database, a data comparison verification module and a communication unit, and a monitoring and acquisition module set in the workshop for collecting data from intelligent numerical control equipment, the monitoring The acquisition module also has a communication unit and is connected to the data communication of the processing center; the database contains the models, categories, workshop distribution and production process data of several intelligent numerical control equipment; the data comparison and verification module is used to identify the Verify the intelligent CNC equipment included in the design data of the intelligent CNC workshop, call the data in the database and / or the monitoring and acquisition module, compare and analyze it with the intelligent CNC equipment data include...

Embodiment 2

[0037] As a preferred embodiment of the present invention, such as figure 1 , discloses an intelligent numerical control workshop design verification system, including a processing center with a database, a data comparison verification module and a communication unit, and a monitoring and acquisition module set in the workshop for collecting data from intelligent numerical control equipment, the monitoring The acquisition module also has a communication unit and is connected to the data communication of the processing center; the database contains the models, categories, workshop distribution and production process data of several intelligent numerical control equipment; the data comparison and verification module is used to identify the Verify the intelligent CNC equipment included in the design data of the intelligent CNC workshop, call the data in the database and / or the monitoring and acquisition module, compare and analyze it with the intelligent CNC equipment data include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com