A graphene oxide-based pretreatment device and its application in food testing

A graphene-based food testing technology, which is applied in the preparation of test samples, test food, material inspection products, etc., can solve the problems of special substances requiring additional operations, and the analysis results of adsorption materials are inconsistent, so as to improve efficiency and improve processing steps. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

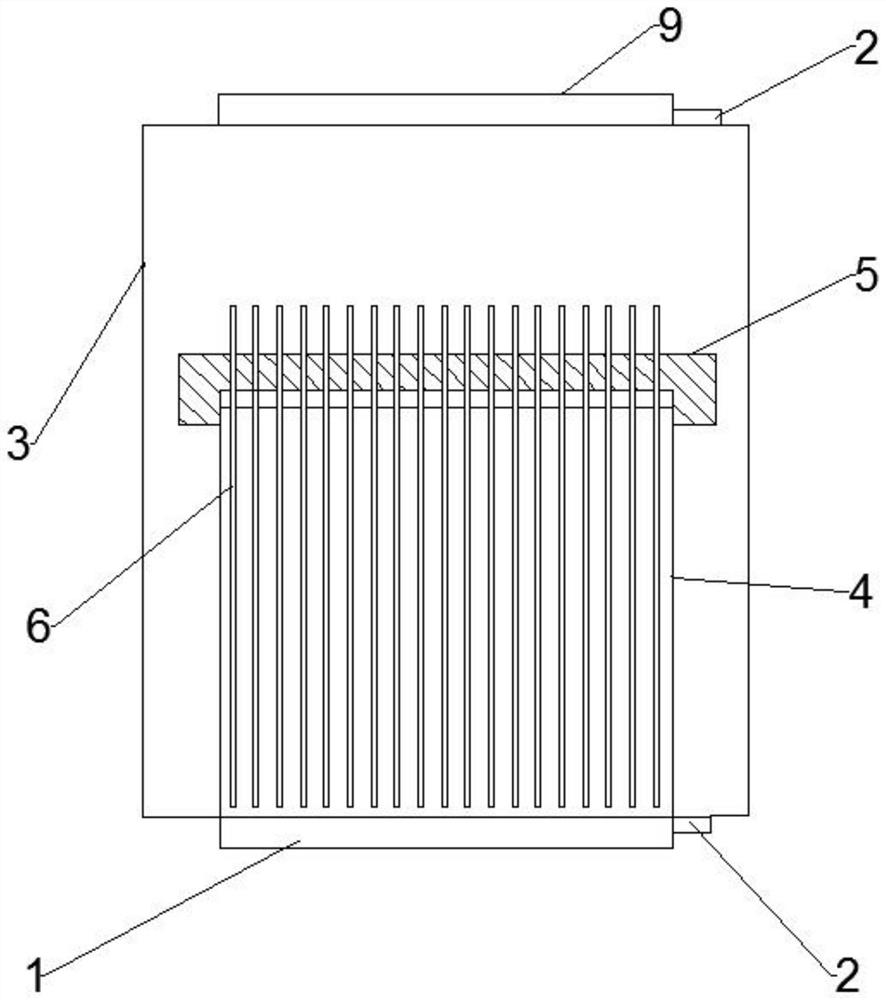

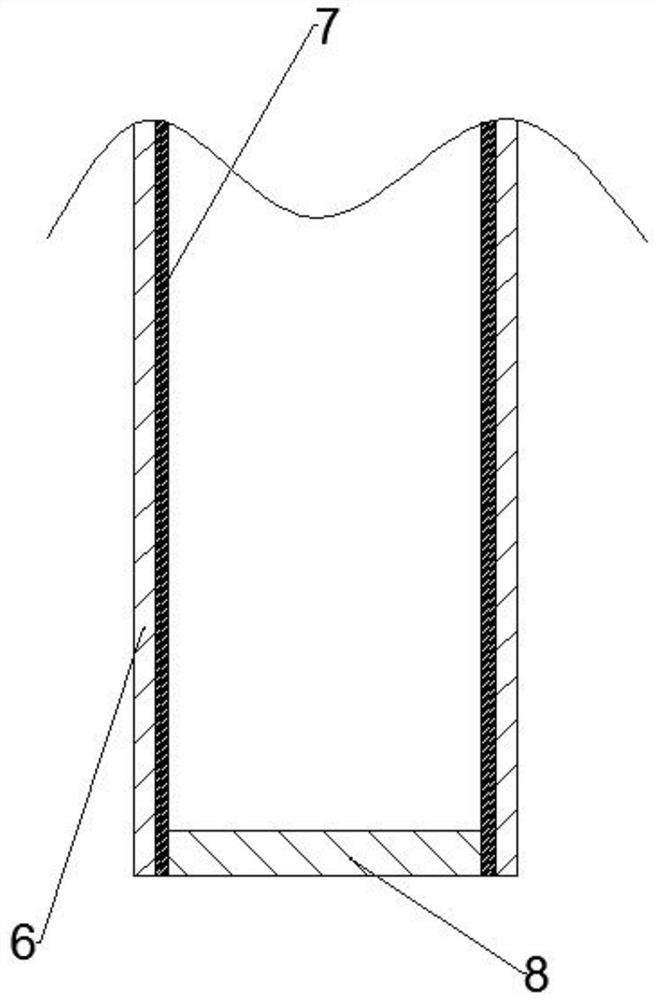

[0040] Such as Figure 1~2 , the present embodiment proposes a graphene oxide-based pretreatment device, including a base plate and a sealed box 3 detachably mounted on the base plate; the upper and lower ends of the sealed box 3 are respectively provided with a first electromagnet 1 and a second electromagnet 9 The sealing box 3 is provided with an upward sample pool 4, and some plexiglass tubes 6 are vertically arranged in the sample pool 4, and the plexiglass tube 6 lower ends are positioned in the sample pool 4, and the plexiglass tube 6 upper ends stretch out from the sample pool 4 Outside the open end of the upper end, the inner wall of the plexiglass tube 6 is covered with a graphene oxide layer 7;

[0041] Also includes the installation cover 5, the opening end of the installation cover 5 is fastened with the opening end of the sample pool 4, the area of the inner top surface of the installation cover 5 covers the opening end of the sample pool 4, and the top surface...

Embodiment 2

[0056] The present embodiment except the following content, all the other parts are identical with embodiment 1; The difference is:

[0057] This embodiment provides the method of using the above-mentioned device for the detection of acrylamide in fried food, by weight, the steps are as follows:

[0058] S1 crushed 4 g of commercially available shrimp crackers, added 16 ml of pure water and 24 ml of mineral oil (liquid paraffin), stirred magnetically for 15 min, and filtered to obtain a filling liquid-water mixture;

[0059] S2 Transfer the filling liquid-water mixture in S1 into the sample cell 4, evenly cover the bottom of the sample cell 4, fasten the installation cover 5 on the sample cell 4, install the sealing box 3, and then open the first electromagnet 1 and the second electromagnet at the same time The battery pack 2 of the second electromagnet 9, adjust the battery pack 2 to make the first electromagnet 1 attractive force greater than the second electromagnet 9;

[...

Embodiment 3

[0064] The present embodiment except the following content, all the other parts are identical with embodiment 1; The difference is:

[0065] This embodiment provides the method of using the above-mentioned device for the detection of acrylamide in fried food, by weight, the steps are as follows:

[0066] S1 Add 25ml of pure water and 35ml of carbon tetrachloride to 5g of a commercially available coffee sample, stir magnetically for 20min, and filter to obtain a filling liquid-water mixture;

[0067] S2 Transfer the filling liquid-water mixture in S1 into the sample cell 4, evenly cover the bottom of the sample cell 4, fasten the installation cover 5 on the sample cell 4, install the sealing box 3, and then open the first electromagnet 1 and the second electromagnet at the same time The battery pack 2 of the second electromagnet 9, adjust the battery pack 2 to make the first electromagnet 1 attractive force greater than the second electromagnet 9;

[0068] S3 When the liquid l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com