Grass density detecting device and mower

A technology for detecting devices and density, which is applied to measuring devices, harvesters, and mechanical devices, etc., can solve the problems of high cost, large error in optical recognition, and lack of widespread popularization, so as to achieve accurate measurement and increase friction , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

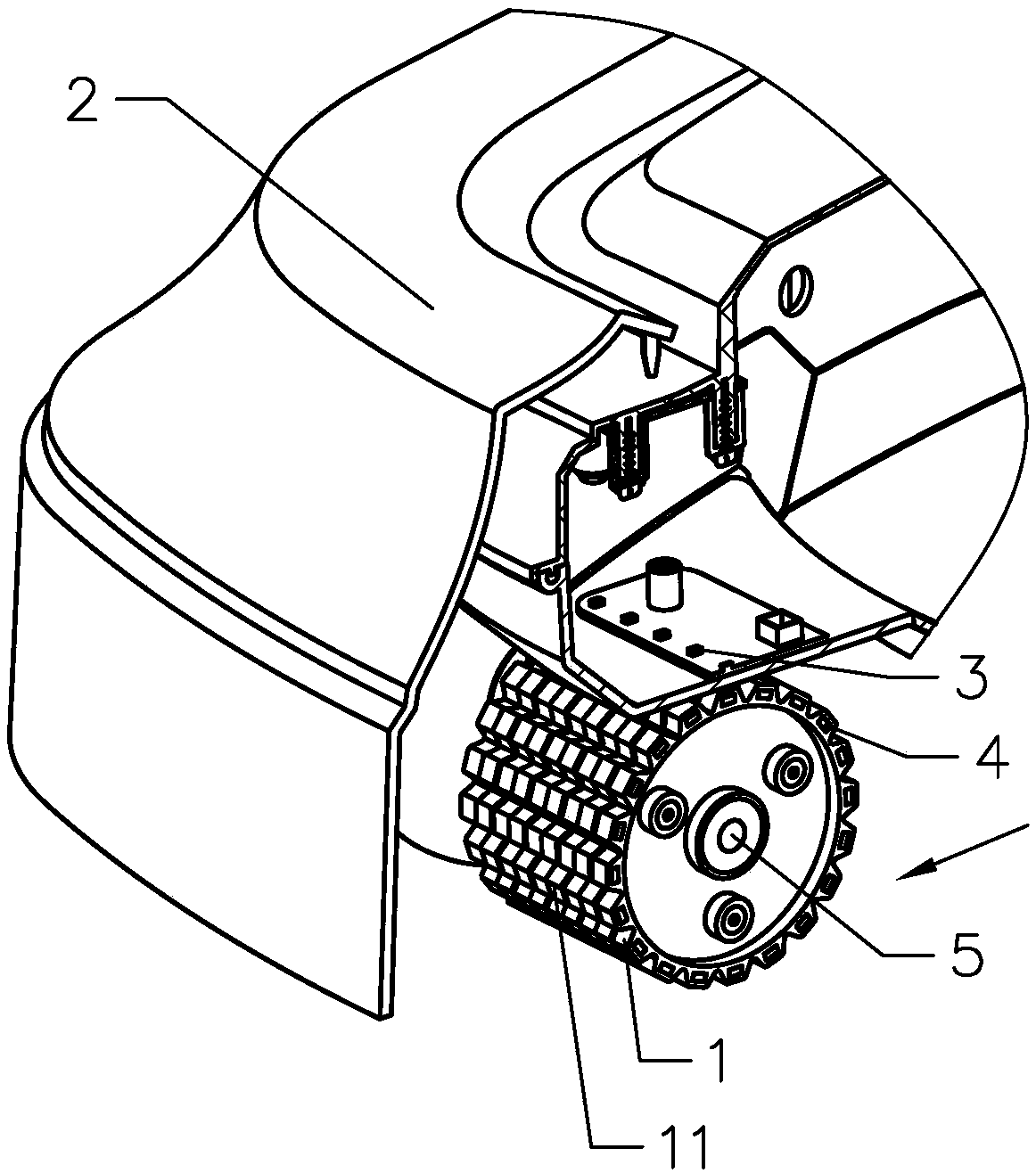

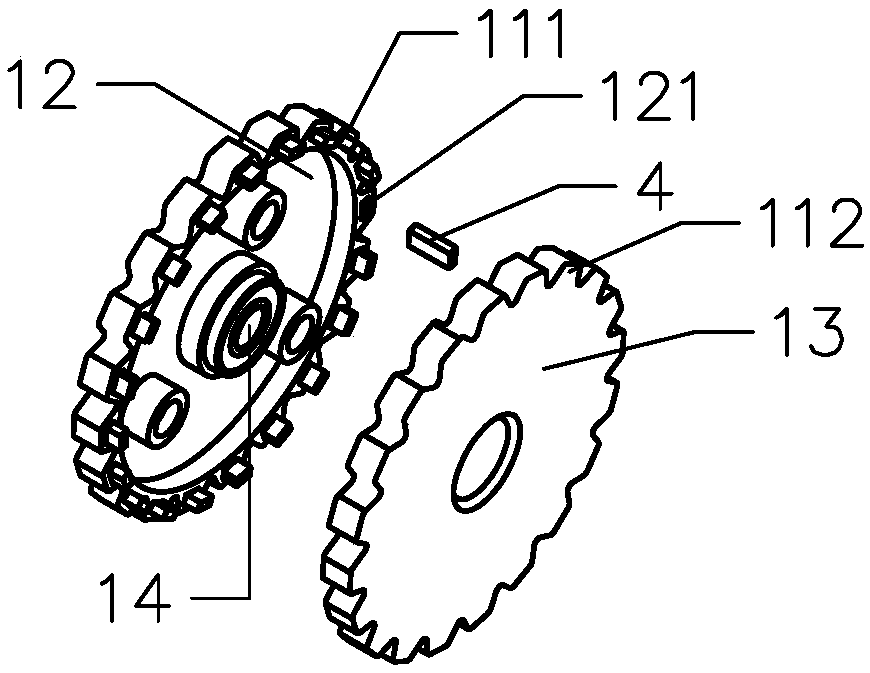

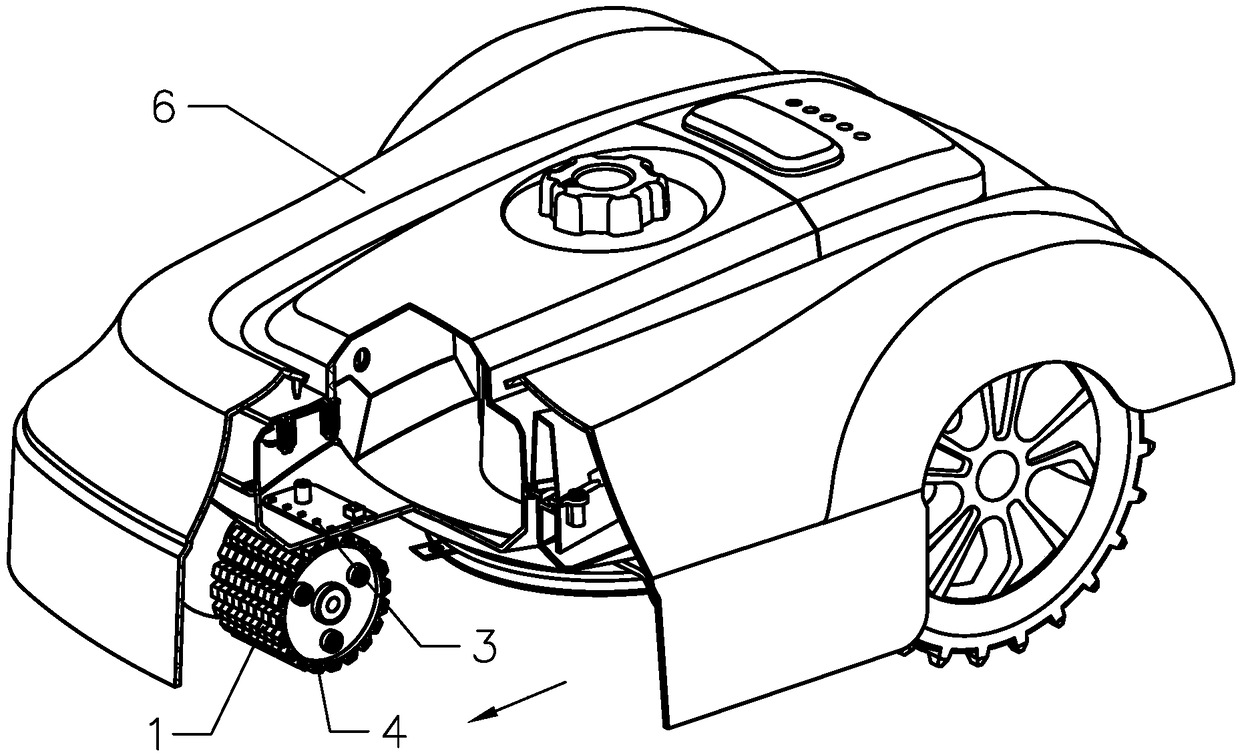

[0031] like figure 1 and figure 2 As shown, the present invention provides a kind of grass density detection device, which is installed on the mobile body 2. The grass density detection device includes a roller 1, which is connected in rotation with the mobile body 2, and the axis of the roller 1 is perpendicular to the mobile body. 2's movement direction setting, figure 1 The direction indicated by the middle arrow is the moving direction of the moving body 2. The circumferential surface of the roller 1 is not in contact with the ground but is in contact with the grass. Because the roller 1 moves with the moving body 2, the grass will generate friction on the roller 1 after the roller 1 contacts the grass. The grass density detection device also includes a speed measuring mechanism for detecting the real-time rotation speed of the roller 1. By measuring the real-time rotation speed of the roller 1, the friction force of the grass acting on the roller 1 can be known to deter...

Embodiment 2

[0047] The main difference between this embodiment and Embodiment 1 is that the speed measuring mechanism includes a photoelectric sensor.

[0048] The speed measuring mechanism includes a photoelectric sensor, and the circumferential surface of the roller is coated with white paint and black paint at intervals. The advantage of this setting is that the white pigment and black pigment make the reflected light and non-reflected light appear alternately, and the photoelectric sensor receives the reflected light signal at intervals accordingly, and outputs intermittent electrical signals, and the real-time rotation speed of the roller can be obtained according to the electrical signals. Know the frictional force of the grass on the roller to judge the density of the grass. Due to the high measurement accuracy and fast response of the photoelectric sensor, the results obtained are more accurate.

[0049] It can be understood that a plurality of reflective plates can also be unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com